Platen Machine Die Cutting Equipment

DONGGUANG CANGHAI PACKING MACHINE CO., LTD.- Species:Die Cutting and Creasing Machine

- Imprinting Type:Platen

- Placing Form of Template:Horizontal

- Die Cutting Tool:Steel Blade

- Computerized:Computerized

- Automatic Grade:Semi-Automatic

Base Info

- Application:Paper Packaging Materials

- Name:Platen Machine Die Cutting Equipment

- Keyword:Platen Machine Die Cutting Equipment

- Color:Green Gray

- Max Speed:60-100 PCS,Min

- Warranty:3 Year

- Feature:Easy Operation

- Function:Cardboard Cutter

- Weight:3000kg

- Voltage:380V

- Dimension:1260*1350*1280 mm

- Transport Package:Waterproof Plastic, Wooden Case, Iron Frame

- Specification:ML750,930,1100,1200,1300,14001500,1600,1800,2000

- Trademark:Canghai

- Origin:Hebei

- HS Code:8441309000

- Production Capacity:1 Set,30days

Description

Basic Info.

Application Paper Packaging Materials Name Platen Machine Die Cutting Equipment Keyword Platen Machine Die Cutting Equipment Color Green Gray Max Speed 60-100 PCS/Min Warranty 3 Year Feature Easy Operation Function Cardboard Cutter Weight 3000kg Voltage 380V Dimension 1260*1350*1280 mm Transport Package Waterproof Plastic, Wooden Case, Iron Frame Specification ML750/930/1100/1200/1300/14001500/1600/1800/2000 Trademark Canghai Origin Hebei HS Code 8441309000 Production Capacity 1 Set/30daysProduct Description

Platen Machine Die Cutting Equipment

corrugated rotary die cutting machine according to the different forms of embossing, mainly divided into three types of rotary die cut machine, flat bed die cut machine, flat platen die cut machine.

corrugated rotary die cutting machine is characterized by line contact, die cutting pressure, high production efficiency, and offset printing machine, flexo printing machine, gravure printing machine and other printing equipment can be connected to the line die cutting, so the scope of application is relatively wide.

Complete Machine Specification

| Code | Max.effective cutting area | Speed | Motor | Weight | Overall Size(L×W×H) |

| ML-750 | 750×520mm | 28±2(strokes/min) | 2.2kw | 2000kg | 1260×1350×1280mm |

| ML-930 | 930×670mm | 23±2(strokes/min) | 4.0kw | 3000kg | 1670×1670×1630mm |

| ML-1100 | 1100×800mm | 20±2(strokes/min) | 5.5kw | 4500kg | 1900×1800×1700mm |

| ML-1200 | 1200×830mm | 20±2(strokes/min) | 5.5kw | 4800kg | 1900×2000×1700mm |

| ML-1300 | 1300×920mm | 18±2(strokes/min) | 7.5kw | 6000kg | 2000×2400×1800mm |

| ML-1400 | 1400×1000mm | 18±2(strokes/min) | 7.5kw | 6500kg | 2000×2450×1900mm |

| ML-1500 | 1500×1050mm | 18±2(strokes/min) | 7.5kw | 7000kg | 2000×2500×1930mm |

| ML-1600 | 1600×1250mm | 16±2(strokes/min) | 11.0kw | 11000kg | 2170×2560×2230mm |

| ML-1800 | 1800×1300mm | 16±2(strokes/min) | 15.0kw | 13500kg | 2240×2800×2130mm |

| ML-2000 | 2000×1400mm | 16±2(strokes/min) | 15.0kw | 14500kg | 2280×2900×2230mm |

Detailed Images

Product features:

1. The casting is made of HT250 gray cast iron, which is annealed to ensure that the casting (including the fuselage and pressure frame) is not easy to deform or break.

2. The spindle is made of four-phosphor chromium steel, which is processed by tempering and tempering to improve the strength, rigidity and hardness of the spindle so as to achieve the effect of non-deformation.

3. The gear of the main part is made of four-phosphor chromium steel, which is processed by tempering and tempering.

4. The lining plate of the guide rail of the machine is made of 38 chromium-molybdenum aluminum. Through nitriding treatment, the hardness is strengthened and it is not easy to wear out.

5. Single-disc electromagnetic clutch is sensitive and reliable.

6. Continuous pressure cutting and open delay function, delay range can be adjusted at will.

7. The driving connecting rod (pulling arm) is made of ductile iron with high strength and toughness and strong tensile strength.

8. Harbin tile bearing is used for key parts.

9. The lubrication system of centralized refueling and manual refueling (optional) can better guarantee the smooth oil path and facilitate the maintenance of the lubrication system.

10. The shaft sleeve of the transmission part adopts compound copper sleeve (to ensure lubrication) and pure copper copper sleeve of the connecting rod.Make the machine more precise.

11. Indentation plate is made of 201# stainless steel plate.

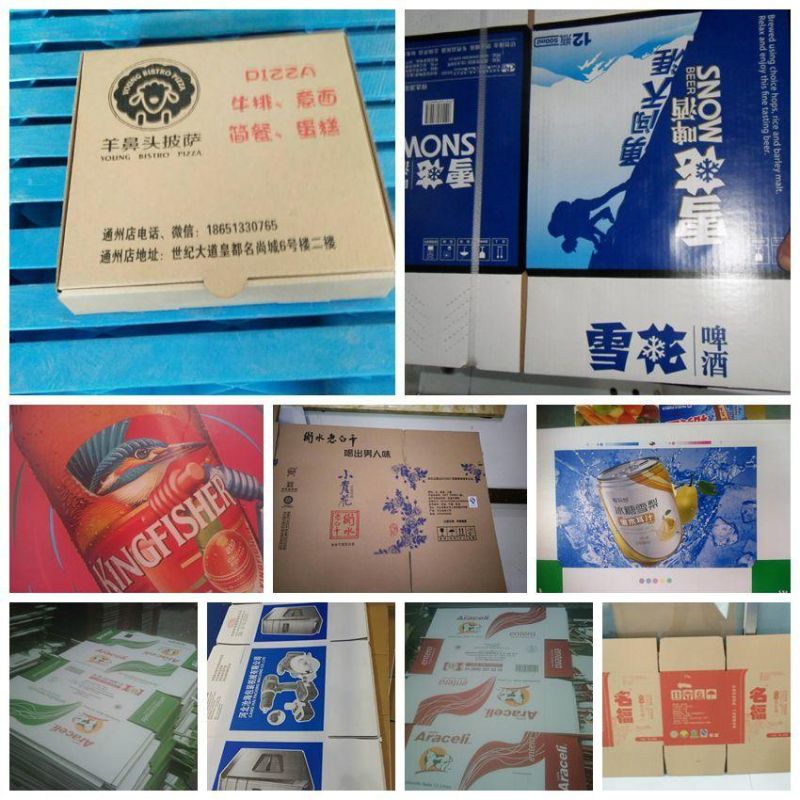

Finished Carton box

Applicable industry

Clothing factory, shoe factory, food factory, pharmaceutical factory, pesticide packaging, beverage packaging box, handicraft packaging, cup packaging, electrical packaging, battery car packaging, children's toys packaging, logistics packaging, furniture packaging, all kinds of small commodity packaging, industrial small parts packaging.

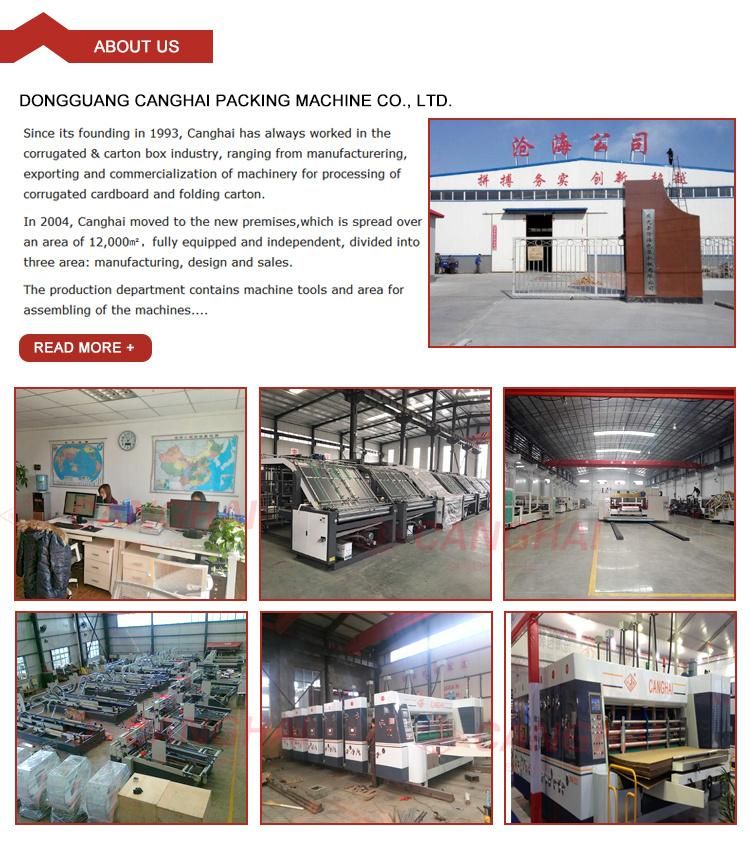

Company Information

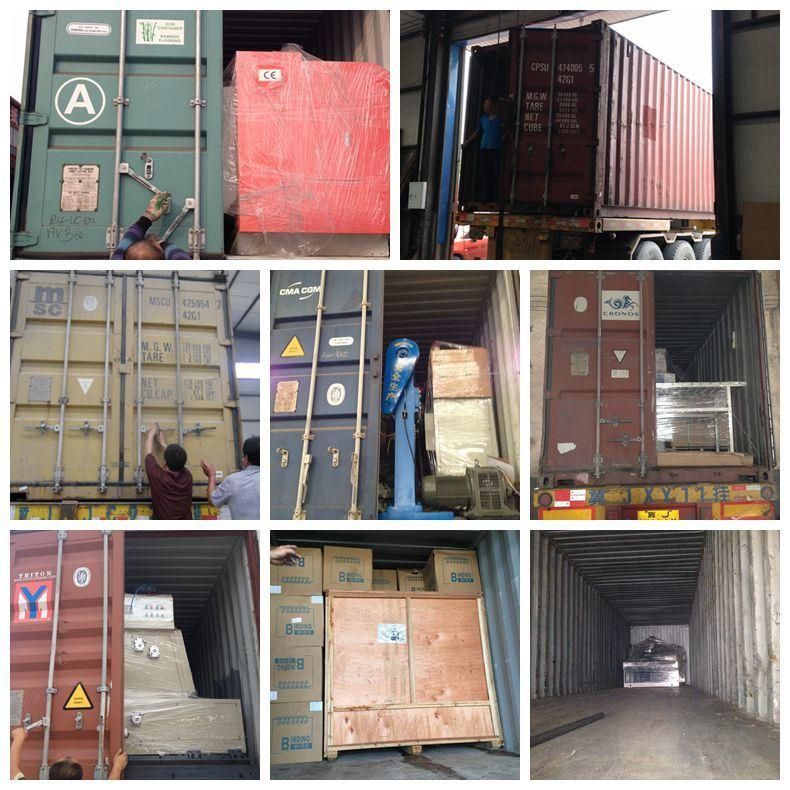

Packaging & Shipping

1)Inside packaging could be iron frame:It is more firm to avoid shake and damage.

2)Outside packaging could be wooden case:The wooden case is of soft texture could reduce damage from impact

3)Waterproof plastic:Keep goods dry and avoid damp

4)We also accept customized regarding the package

Customer visit

For now, we have client from South east Asia and south Asia, Middle east, Europe, American, Africa and so on place. They buy not only chain printing slotting die cutting machine but also other product we supplied.In addition, we could help customer to order other product we dont production.Customers are welcome to visit our factory and most of them satisfied with our product quality, factory scale as well as our service.If you are interesting, please dont hesitate to come meet us!

Certificate

Our Services

1)Three years warranty for machine.Technical to door service.

2)English manual and Video for machine using and maintenance.

3)We offer free training in our factory, welcome to visit and learn more about our machines.

4)Free accessories:Software ,manual, book, videos, USB control

FAQ

1.Are you a trading company or factory?

We are the manufacturer and also we have import export license.

2.Where is your company located?How can I visit there?

Our factory address:Dongguang county, Cangzhou city, hebei province,China

3.Can you send technician for installation and training?

Yes, we can send our technician abroad for installation and training, but all the charges must be paid by buyer, such as the plane tickets (a round trip), meals, hotel, traffic etc.

4.Whats your warranty time

We can take 3 years warranty, actually our longest cooperation customer have been using our product for more than 10 years with no problem.