High-Gloss Digital Photo Paper and Inkjet Paper Coating Machine Product Line

QINGDAO JIERUIXIN MACHINERY AND TECHNOLOGY CO., LTD.- Type:Air Doctor Coater

- Driven Type:Electric

- Automatic Grade:Automatic

- Packaging Material:Wood

- Packaging Type:Wooden Package or Customized

- Application:Making Paper

Base Info

- Model NO.:jrx

- Design Speed:100m,Min

- Width of Base Paper:2650mm

- Width of Net Paper:2600mm

- Coating Weight:2-10G,M²(Max)

- Work Speed:60-100m,Min

- Transport Package:Wooden Package or Plastic Film

- Specification:customized

- Trademark:JRX machinery

- Origin:Shangdong, China

- HS Code:8501330000

- Production Capacity:60 Set,Sets Per Year

Description

Basic Info.

Model NO. jrx Design Speed 100m/Min Width of Base Paper 2650mm Width of Net Paper 2600mm Coating Weight 2-10G/M²(Max) Work Speed 60-100m/Min Transport Package Wooden Package or Plastic Film Specification customized Trademark JRX machinery Origin Shangdong, China HS Code 8501330000 Production Capacity 60 Set/Sets Per YearProduct Description

High-Gloss Digital Photo Paper and Inkjet Paper Coating Machine Product Line

About production:

(1) Double- gyration paper feed frame :1 set

unwinding roll diameter: Max 1200mm

Width: 1300mm

paper-rolling drum diameter: 3 " air swelling shaft

unwinding Type: Rotary Eject

Tension: 540-1450kg / m

The Double- gyration paper feed frame composed of the rack, rotating arm, rotary worm gear box, brake and centre.

1)Rack: 1 set , painted steel plate welded. Foundation slab is the casting.

2)Rotating arm :1 set , painted steel plate welded, rotating arm driven by a worm gear box rotary swing.

3)rotary worm gear box: 1 set ,made of painted steel.

4)Centre: four sets, made of painted steel.

5) Air swelling shaft :2 sets, 3 " specialized factory production.

6)Brakes:1 set, equipped with a magnetic clutch brake.

7)Electrical control system :1 set, Equipped with electrical components used for electrical control and so on.

(2)Back coating device: 1 set

Feeding roller: ø170X1400 (steel roller rubber coating)

Coating roller: ø270X1400 (steel roller rubber coating)

Pneumatic pressure device :1 set

The feeding roller gap adjusting device :1 set

Coating tank device: (304 stainless steel)

| The equipment voltage: | 3 × 380/50 V / Hz |

| Equipment voltage: | 220/50 V / Hz |

| Equipment voltage: | 24 VDC |

| Compressed air pressure: | 0.5 M pa |

| Water pressure: | 0.3 M pa |

| Water temperature: | 25-37 ° C |

| Cooling water pressure: | 0.3 M pa |

| Cooling water temperature: | 5-15 ° C |

| Drying oven steam pressure: | 0.8 M pa |

| Indoor ambient temperature: | +3 / +30 ° C |

| Ambient humidity: | 75-90% |

About our company

QINGDAO JIERUIXIN MACHINERY AND TECHNOLOGY CO., LTD.

We are QINGDAO JIERUIXIN MACHINERY AND TECHNOLOGY CO., LTD., which company is mainly working on paper coating machine, paper making machine and related technology. Through more than 20 years effort, Besides the machine self, we have our own chemist and prefer to supply chemical, formulation, technology and other suggestion to customers. Then our formulation will match our machines, and get the best quality paper for them. Now Our company had been one of the famous paper coating machine manufacturer in China and our coating machine and technology had been exported to Iran, Egypt, Mexico, Australia, India and etc.

Our factory

Exhibition

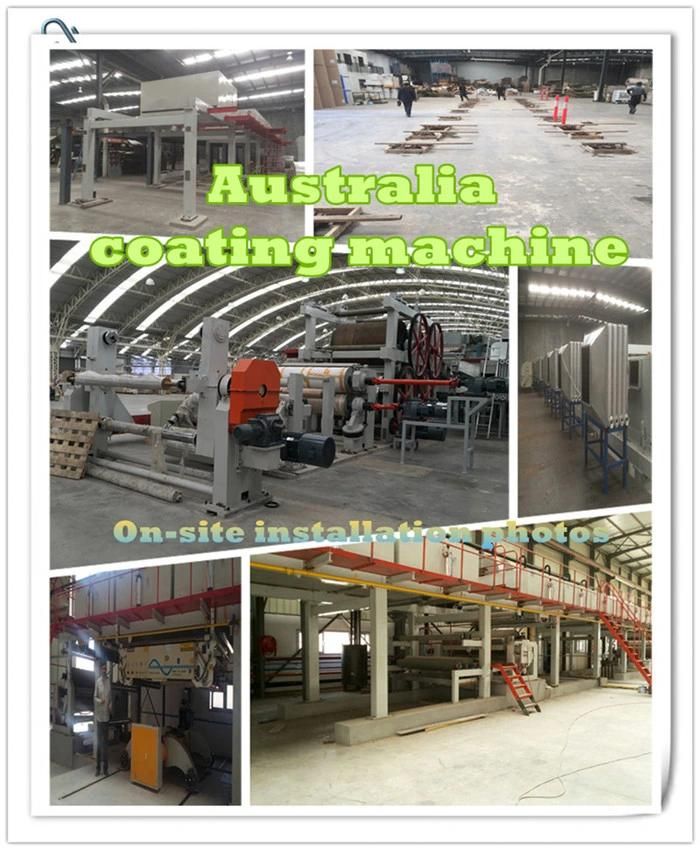

Overseas projects

Our company establishes a cooperative relationship with Australia, Mexico, Egypt etc. Our engineers will help install and test the machine exported.

Our professional team usually go abroad to tell them how to use the equipment, and will supply technical support of your worker training.

Packing and shipment

Our Services

1. Reasonable suggestions for selection of equipment.

2. Provide detailed description and assembly drawing, to make you more aware of the device's ability to work.

3. Engineers on-site equipment installation and commissioning.

4. Provide training for your employees.

5. Professional technical guidance and technical support during your production, make sure the device's work properly and production.

6. Equipment upgrade & remould.

7. We will testing installation machine in the factory workshop, to ensure safety and quality.

8. Supply chemical, formulation, technology and other suggestion to customers.

FAQ

1. How long does your product quality warranty last?

One year for all our products against any nonartificial quality problem since the product leave our factory.

2.What is your payment term?

It depends on your paper or pulp making technology.

Generally 60days after we receive the deposit or the prepayment. We will confirm you when we stat to ship.

3.Could your engineer teach and train our worker and stay in our factory for long time?

Yes, we have installation engineer team, they can train and teach your worker to operate paper machine, during which their salary is paid by you.

4.Can I visit your company?

Yes, you can.

It would be our honor that you can come and visit us.

√ If you want to know more information, please contact me!