UV Cold Foil Cold Stamping Machine with Convex Cold Foiling Snowflake Ice Flowers Embossed Wrinkle Detonating Machine

Shantou Sinhosun international trade co., Ltd.- After-sales Service:Lifetime Service

- Warranty:One-Year Warranty

- Classification:Screen-Printing Cold Foil Machine

- Plate Type:Screen Printer

- Color & Page:Multi-Color

- Suitable Material:Paper

Base Info

- Model NO.:SH-1050CF

- Automatic Grade:Automatic

- Application:Business Card, Plastic Flexible Packaging, Arts and Crafts, Labels and Tags

- Usage:Label Printer, Paper Printer

- Hot Stamping Pressure Factor:Cold Stamped by a Screen-Printing

- Decisive Factor:Cold Foil Paper

- Type:Automatic Screen Printing Machine

- Style:Screen-Process Printing Press

- Structure:Flat-Bed Cylinder Press

- System Supported:Windowsxp32

- Print Interface:USB2.0

- Max. Sheet Size:1050&*750mm

- Min. Sheet Size:560*350mm

- Conveying Speed:800-4000 Sheets,Hour

- Paper Thickness:157-450g

- Power for UV Detonation:12kw

- Power for UV Curing:35kw

- Power for Cold Foil Printing:35kw

- Size of The Machine:5950*2700*2100mm

- Transport Package:Wooden Case

- Specification:5950*2700*2100mm

- Trademark:SXL

- Origin:China

- HS Code:8441309000

- Production Capacity:200 Pieces,Year

Description

- Touch screen control

- With automatic sheet patting and alignment control; automatic lifting of the paper table and intelligent paper counting function, etc.

Conveying

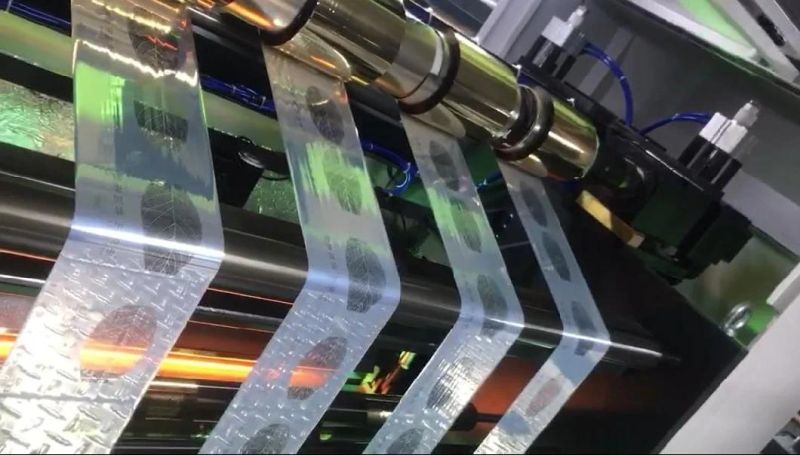

Conveying- The snowflake section is conveyed by a Teflon flat belt, so that there will be no net shadow when the product blasts snowflakes; the air-conditioning is conveyed by a Teflon mesh belt. The device is equipped with a fully automatic correction system, thus the conveyor belt will not be damaged due to deviation.

- The converter can adjust speed freely and the speed range can be adjusted to 10M-60M/Min.

- The automatic turning conveyor is a paper transfer mechanism that connected to the screen printing machine. The conveyor table can be lifted and turned at 90°, which is convenient for cleaning and maintenance of the screen printing machine.

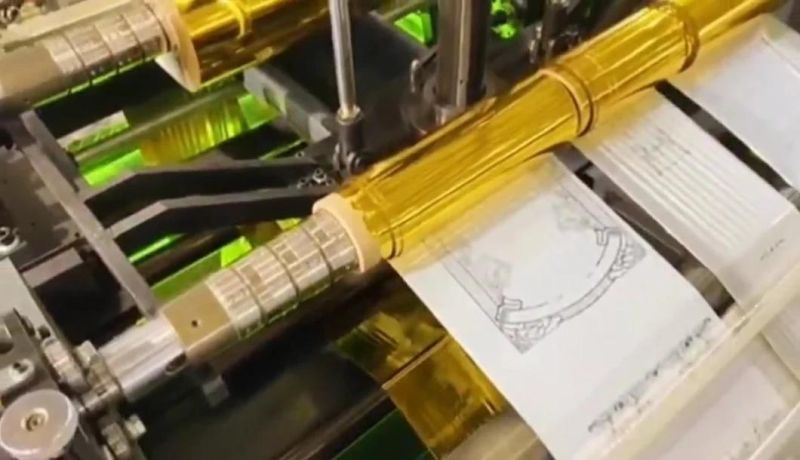

Snowflake wrinkle

Snowflake wrinkle- There're 3*40W wrinkle (MK) lamps, divided into 3 groups of control, adjustable height, convenient for customers to adjust.

- There're 2*2.5KW leveling (KF) lamps and controlled in 2 groups to make the product leveling better.

- Snowflake lamp adopts 1*8KW stepless dimming electronic power supply and the adjustment range is 10%-100%. Customers can adjust the lamp power to change the snowflake's detonation situation, so the adjustment range is more flexible and accurate.

Cold foil UV

Cold foil UV- UV curing adopts 2*12KW UV mercury lamps stepless dimming electronic power supply, the adjustment range is 25%-100%, customers can adjust the curing power according to the curing situation of the product to achieve refinement. Compared with traditional transformer + capacitor mode, stepless dimming power supply can save power by 15%-20%.

- There is a UV IR filter and a shutter baffle underneath the UV lamp to insulate heat and protect the tube.

- The UV curing mechanism has a special structure and an ultra-low temperature design. With independent research and development patents, the advantage is that the product can be cured within 55° when it exits the UV mechanism, so that the product is not easy to deform, resulting in paper jams or misregister.

- When there is no paper passing by, the UV lamp of paper-passing electric eyes mechanism will automatically turn into standby power to save electricity.

- The rewinding and unwinding device adopts a high-precision digital display automatic tension control system, which makes the rewinding and unwinding in high precision and the operation is stable and smooth.

Air cooling(Optional)

Air cooling(Optional) ServiceSXL give our heartfelt thanks for your choosing of our products, service is our core. Our "lifetime worry-free service" covering the whole life cycle of equipment from service efficiency, service speed, maintenance cost and quality standard, and realize a customer-oriented value chain.

ServiceSXL give our heartfelt thanks for your choosing of our products, service is our core. Our "lifetime worry-free service" covering the whole life cycle of equipment from service efficiency, service speed, maintenance cost and quality standard, and realize a customer-oriented value chain.Pre-sale

According to your requirements and the providing box sample specification , our sale person will provide professional technical consultation services, and develop relevant solutions, and providing the performance and characteristics of products, etc.. In the early stage, sale person will communicate with you, ensure the models and specification of the equipment. Also we can custom machine for your special requirements, providing you a satisfactory reasonable production line.

After-sales

1. Establish one machine and one record management system

Our company implements the whole-process tracking management system from the factory to the useful lifespan of the products. Archiving management including the product name, specification model, factory number, date and user information , also including product acceptance registration, product assembly, the factory state, installation, customer situation, training, warranty and maintenance period of technology, quality records, and product transfer track records, etc, to ensure the quality security work of each sold equipment .

2. One-year warranty and lifetime service

From the day of equipment acceptance, we will provide free parts replacement services to you during warrant period, the freight of parts will be borne by buyer.

After one-year warranty, if your equipment failure, we will provide technical assistance, and provide you with paid maintenance services, including fault maintenance, replacement of the original factory parts.