Automatic Core Pulling 150-280m/Min Henan China Sheeting Paper Cutting Machine

Qinyang Haiyang Paper Machinery Co., Ltd. Zhengzhou Branch- After-sales Service:1 Year

- Warranty:1 Year

- Classification:Single-blade Cutter

- Driven Type:Electric

- Type:Living Paper Cutting Machine

- Blade Material:Stainless Steel

Base Info

- Model NO.:1092,1575,1880,2100,2400

- Computerized:Computerized

- Paper Width(mm):1092mm,1575mm,1880mm,2100mm,2400mm

- Paper Diameter(mm):1200mm(Please Specify)

- Paper Core Inner Diameter:76mm(Please Specify)

- Product Diameter:40mm-200mm

- Production Speed:150-280m,Min

- Power Configuration:380V50Hz

- Required Air Pressure:0.5mps(The Self)

- Outline Dimension:6200mm-7500mm*2600mm-3200mm*1750mm

- Machine Weight:2900kg-3800kg

- Punch:2-4 Knife,Spiral Cutter Line

- Paper Backing:1-4layer,General Chain Feed

- Hole Pitch:Positioning of Belt and Chain Wheel

- Product Range:Core Paper,Non Core Roll Paper

- Drop Tube:Manual,Automatic(Optional)

- Non Core Roll Paper:Automatic Core Pulling

- Transport Package:Wooden Case & Plastic Film

- Trademark:haiyang

- Origin:Henan China

- HS Code:843920000

- Production Capacity:100 Sets,Year

Description

3. Productiong Process

Working Principle

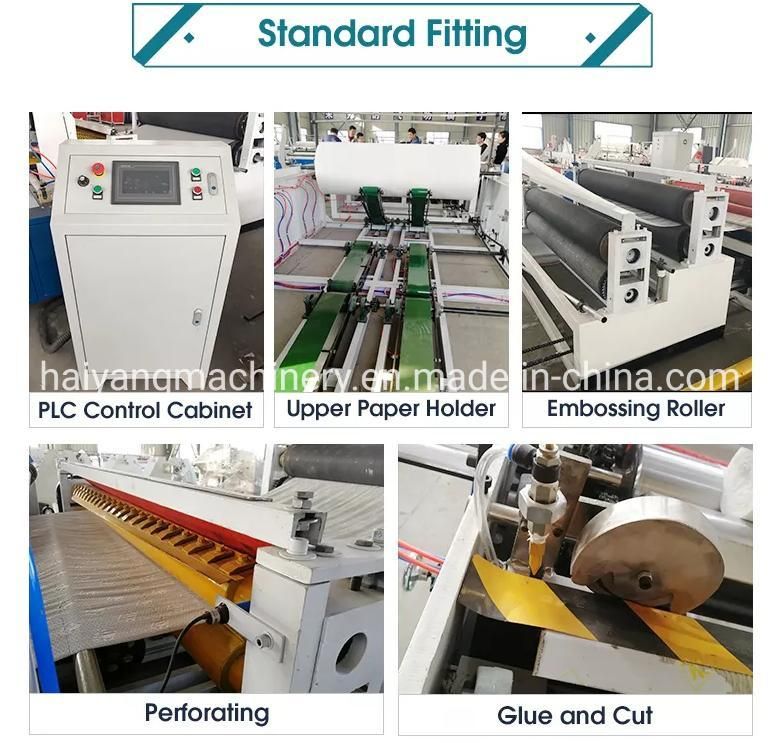

Four-roller automatic feeding→synchronous conveying→embossing→punching→automatic winding→cutting→packing→sealing.

1. Rewinding---The main purpose of the toilet paper rewinding machine is to process the large shaft paper into a long strip of toilet paper roll.

2. Cut the paper---The long piece of toilet paper cut by the paper cutter is cut into semi-finished products of the length required by the customer.

3. Packaging---Packaging can be packaged in a packaging machine or manually wrapped, and the semi-finished products of the toilet

paper are packaged and sealed by a sealing machine.

4. Performance Characteristics

1. Using PLC computer to program the finished paper in the rewinding process to achieve the tightness and looseness of the different

tightness to solve the looseness of the finished product due to long-term storage.

2. Full-automatic rewinding machine can choose double-sided embossing, gluing compound, which can make paper more soft than single-sided

embossing, the effect of double-sided finished products is consistent, and each layer of paper does not spread when used, especially suitable for

processing. Roll up kitchen paper towels and reduce weight by 15% or more when finished in the same size.

3. The machine is equipped with processing unintentional, solid, paper tube toilet paper, which can instantly switch between products, and can

also be selected according to user needs.

4. Automatic trimming, glue spraying, sealing, and shafting are completed synchronously, so that there is no paper loss when the roll paper is

cut into the band saw and packaged, which greatly improves the production efficiency and the grade of the finished product. Easy to enable.

5. Pneumatic belt feeding, double reel and each axis of the original paper have independent tension adjustment mechanism

5. Company profile

Qinyang City Haiyang Paper Making machinery Co.,Ltd has developed into a much more competitive company since

Qinyang City Haiyang Paper Making machinery Co.,Ltd has developed into a much more competitive company sinceestablishment in 1999. We mainly manufactures all kinds of paper machines, toilet paper production line, Kraft paper production line, copy/writing paper production line. We have 4 paper machine producing workshops and one international trade department, and more than 110 workers and more than 20 engineers. Our factory total area is 20,000(96000)square meters. We sincerely welcome clients from all over the world visit our factory, any requirement, please contact via email, we will reply you as the first priority.

7. Purchase Guide:

1.We have napkin paper machine,toilet paper machine,facial tissue paper machine and pocket tissue paper machine.etc. Firstly,what machine are you looking for ?

2.The one that you are checking is the toilet paper machine,there are various models for choice,1092,1575,1760 and 1880,etc. Which model do you want ? Among them,the

model 1575 is the most popular to export abroad,and the 1880 Model is the most popular in China.

3.Usually to make the toilet paper machine,three machines are needed,it contains rewinding machine,cutting machine and sealing machine.This is basic three machines.

4.Do you make the toilet paper roll with inner core or without inner core ? If you will make toilet paper with inner core,the paper core making machine is optional.Of course

you can buy finished paper core directly to use.

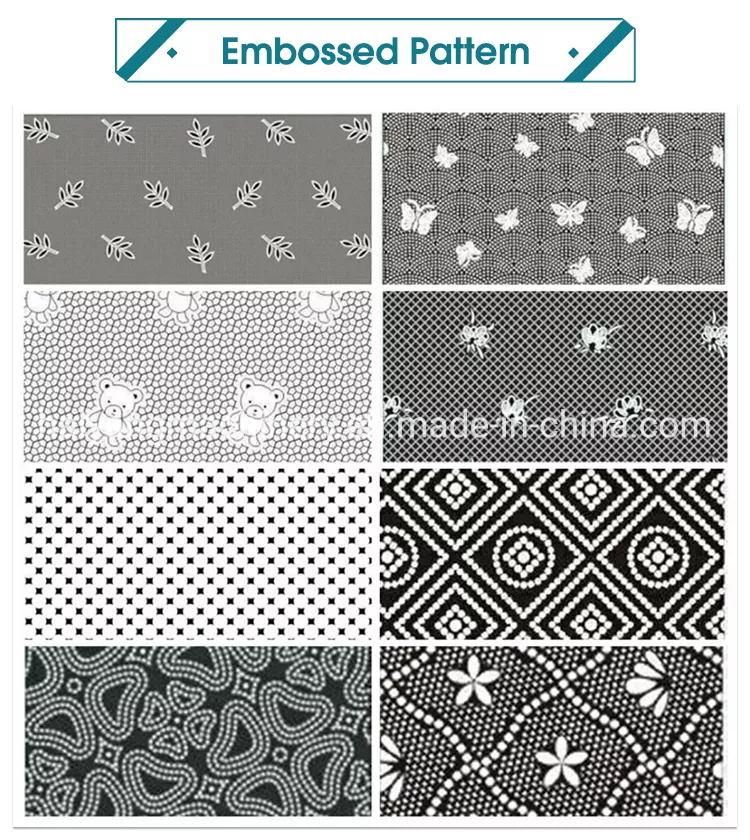

5.For the toilet paper rewinding machine,do you need embossing or not ? The basic function has no embossing function,if you need embossing,single embossing or double embossing ?

6.If you want embossing function,what embossing pattern do you want ? The embossing patterns can be designed as your request.Of course we also can supply some patterns designs for choice.

7.If you will make the toilet paper roll with inner core,do you need automatic paper core dropping function ? This is optional function.If no paper core dropping function,the machine

also can do both toilet paper with inner core and without inner core.

8.The rewinding machine own functions include automatic rewinding,perforation,cutting,glue spraying,automatic pneumatic paper loading,and automatic synchronous belt. Other functions are optional.

If you have any suggestions or opinions about our products, please leave a message, and we will immediately answer your questions. Thanks for your support.

Thanks for your cooperation!