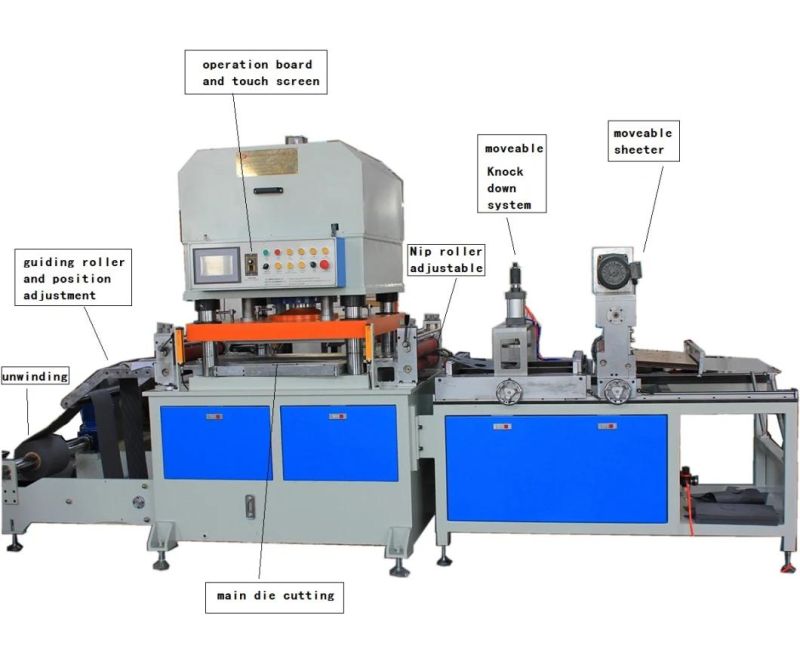

Large Size Automatic Roll to Roll Die Cutting Machine

Kunshan Dapeng Precision Machinery Co., Ltd.- Species:Hydraulic Die Cutting Machine

- Imprinting Type:Platen

- Placing Form of Template:Horizontal

- Die Cutting Tool:Steel Plate

- Computerized:Computerized

- Automatic Grade:Automatic

Base Info

- Model NO.:DP-700J

- Application:Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials, Earthquake Products

- Max Cutting Area:1000*800mm

- Cutting Force:40 Ton

- Transport Package:Wodden Case

- Specification:SGS

- Trademark:DP

- Origin:Kunshan, Jiangsu, China.

- HS Code:844110000

- Production Capacity:50 Sets,Month

Description

Basic Info.

Model NO. DP-700J Application Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials, Earthquake Products Max Cutting Area 1000*800mm Cutting Force 40 Ton Transport Package Wodden Case Specification SGS Trademark DP Origin Kunshan, Jiangsu, China. HS Code 844110000 Production Capacity 50 Sets/MonthProduct Description

DP-650 Hydralic Die-Cutting Machine for Roll Materiallarge size automatic roll to roll die cutting machine

Powerful, Precise, Fast.

Suitable for roll materials

Available in a wide range of powers from 8 tons to 80 tons with cutting surface from 650mm*600mm up to 1000mm*800mm.

Functional Characteristics

Flexible and convenient operation,

Photoelectric registering system,

A programmer controller (PLC)

Kiss Cut, through cut both available.

Anti-vibration machine feet,

A cutting speed up to 20-90 punches per minute.

Scope Application

It is applied to cut various materials, such as Rubber, Plastic, Paper Board, Aluminum Foil, Cooper foil, PET, Protective film, Mylar, Reflector, Diffuser, Gaskets, Silicon Tape etc.

Our kiss cutting flat-bed machines are studied and manufactured to make kiss-cutting and total cutting of any technical flexible material.

The kiss cutting machines are provided with strong steel bodies, they require very low maintenance and they have a simple and quick set up.

They can be easily managed and they can make simple and complex kiss cutting productions with accuracy and high quality standards.

All our kiss cutting flat-bed machines are managed by touch screen which can memorize a very high number of programs and ensure quick and easy set up and kiss cutting production process.

Kiss cutting high speed and high versatility with easy and fast set up

studied and manufactured to grant high precision, reliability and a very long life, allowing our customers to save their money.

Recommended for simple and complex productions, the kiss cutting flat-bed machines can be equipped with many optional systems to ensure excellent results in technical material kiss cutting converting in many different lines of business:

- Adhesive/double sided adhesives kiss cutting/total cutting

- Car emblems kiss cutting/total cutting

- Automotive kiss cutting/total cutting

- Abrasive materials kiss cutting/total cutting

- Plastics kiss cutting/total cutting

- Foam kiss cutting/total cutting

- Felts kiss cutting/total cutting

- Filters kiss cutting/total cutting

- Medical sector kiss cutting/total cutting

- Electronics kiss cutting/total cutting

- Gaskets kiss cutting/total cutting

- Labels kiss cutting/total cutting

- Rubber kiss cutting/total cutting.

Kiss cutting machines with high modularity

Our kiss cutting flat-bed machines can be equipped with a high variety of optional systems in order to make with accuracy the following productions:

- lamination

- material feeding

- kiss cutting/total cutting at register

- scrap rewinding

- knock-out of the totally cut parts

- stacking

- remove or add a liner

- rewinding on one or more rolls

- cut the material in set (guillotine).

Kiss cutting with high quality and price

Our kiss cutting flat-bed machines are entirely mechanical and electronic, therefore they require a low maintenance, saving on the electric consumption and ensuring an easy utilization. Thanks to a software with an immediate interface, our kiss cutting machines have a high precision, which grants a very little waste of material.

They are strong machines, able to work on more than one shift and to grant high cutting precision for all their long life.

The kiss cutting flat-bed machines are also extremely versatile and they allow to make various productions on different materials, simple or complex.

High quality construction, high precision, silence, power and quality/price represent our cutting systems distinctive mark in the world.

Packing :

Wooden case packing

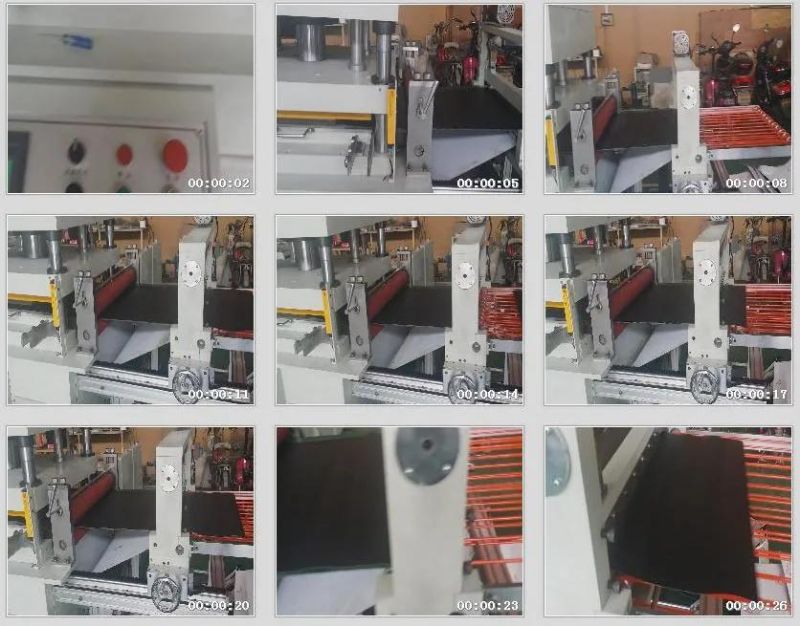

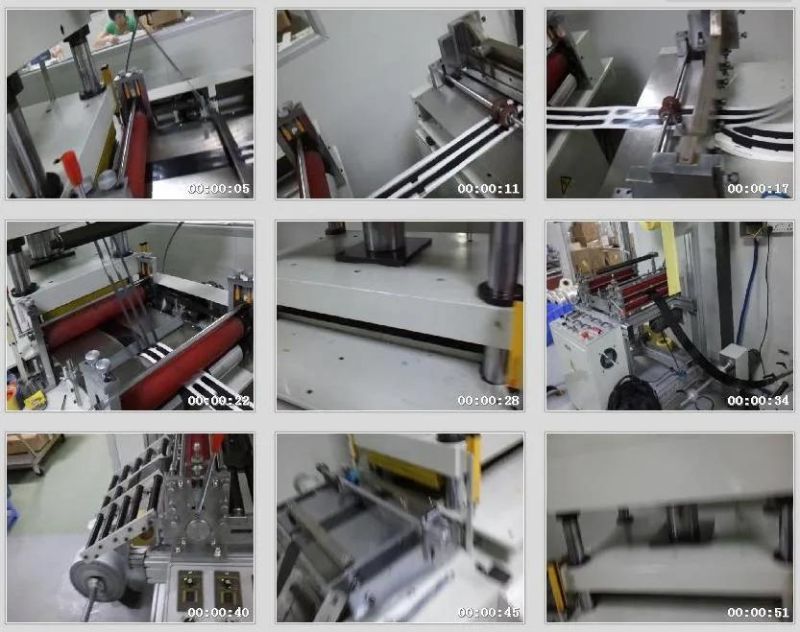

Our this machine video :

http://youtu.be/WGzsM48bmdU

http://youtu.be/SkgTtBaVMzo

Machine working picture :

through cut die cutting machine :

kiss cut hydraulic die cutter :

| Model | Working Area | Max Tonnage | Max Feeding Width | Drive Motor | Weight | Outline Dimension | Position Accuracy | Power |

| DP-650 | 650mm*600mm | 40t | 650mm | 7.5HP/5.5KW | 3 Ton | 1940mm*1500mm*1790mm | ±0.01 mm | 380V 50HZ |

| DP-850 | 850mm*600mm | 40t | 850mm | 10HP/7.5KW | 3.4Ton | 2140mm*1500mm*1790mm | ±0.01 mm | 380V 50HZ |

| DP-1000 | 1000mm*800mm | 80t | 1000mm | 15HP/11..2KW | 4.5Ton | 2290mm*1500mm*1790mm | ±0.01 mm | 380V 50HZ |