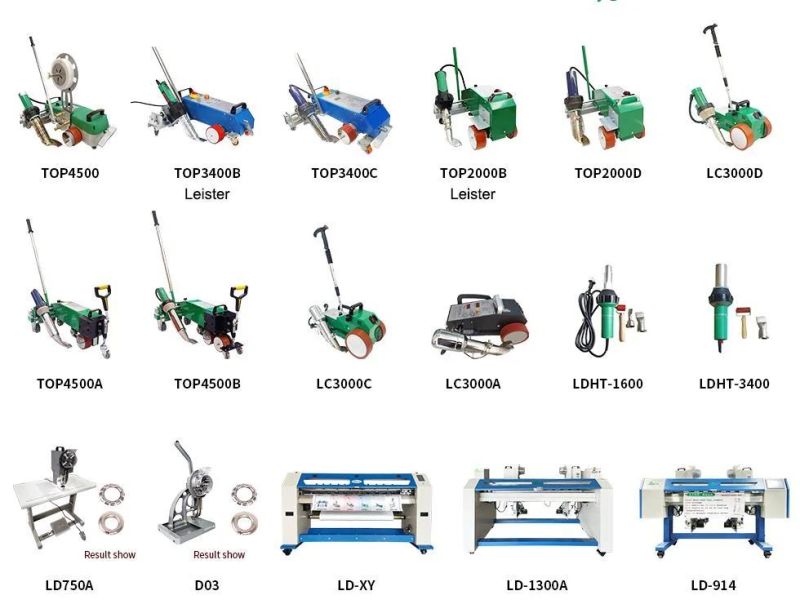

Automatic Eyelet Pressing Machine Hole Making Machine Buttonhole Machine

Zhengzhou Liudu Mechanical Electrical Equipment Co., Ltd.- After-Sales Service Provided:Factory After Sale Service

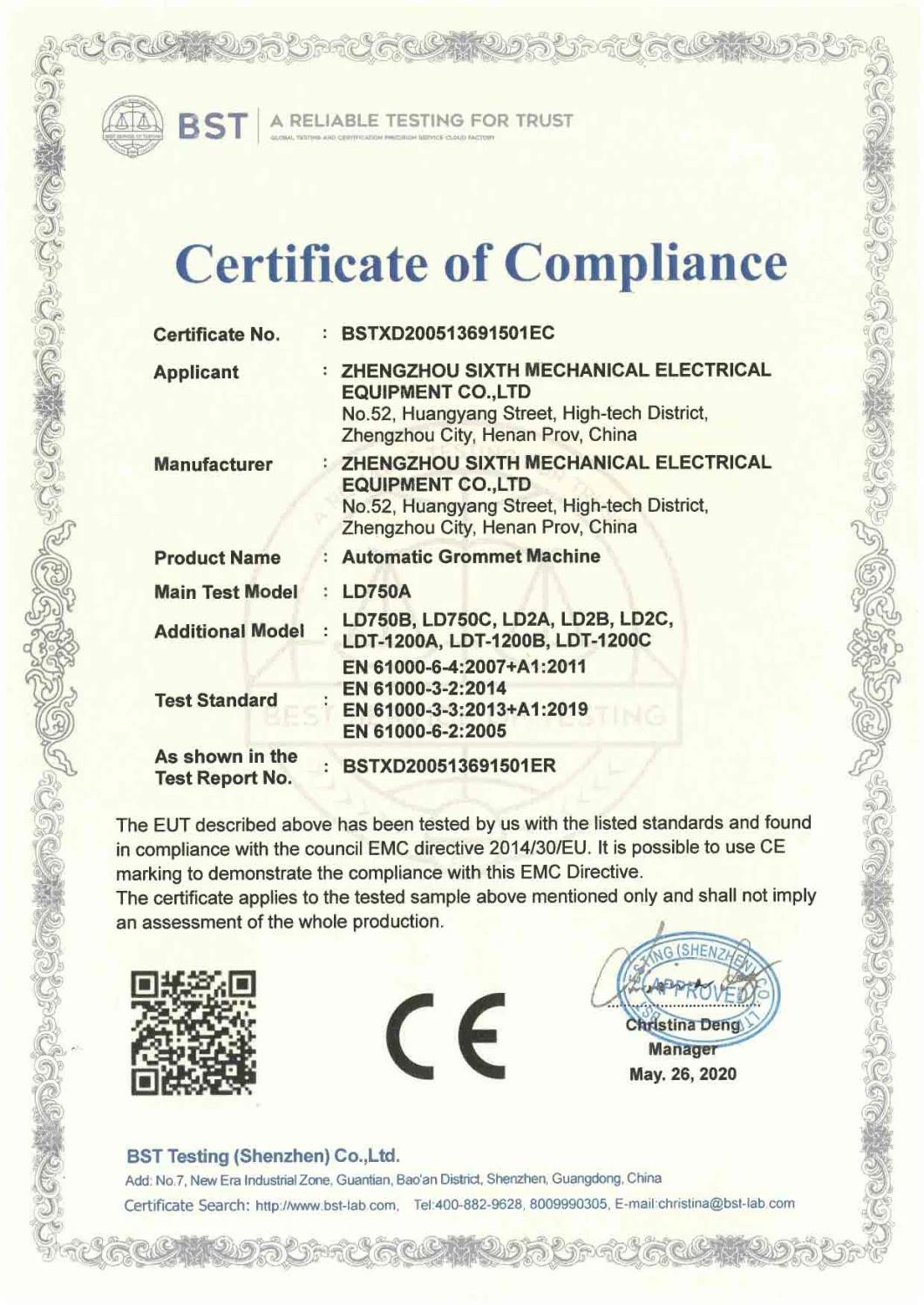

- Certification:RoHS, CE

- Controlling Mode:Automatic

- Power Source:Electricity

- Condition:NEW

- Type:Automatic Hole Puncher

Base Info

- Model NO.:LD750A

- Hole Number:One

- Voltage:220V

- Product Name:Automatic Eyelet Machine

- Size:10mm, 12mm, 6mm, 5.5mm, 8mm

- Transport Package:Wooden

- Specification:10mm, 12mm, 5.5mm, 6mm, 8mm

- Trademark:LIUDU

- Origin:China

- HS Code:8479819000

- Production Capacity:1000PCS,Month

Description

Basic Info.

Model NO. LD750A Hole Number One Voltage 220V Product Name Automatic Eyelet Machine Size 10mm, 12mm, 6mm, 5.5mm, 8mm Transport Package Wooden Specification 10mm, 12mm, 5.5mm, 6mm, 8mm Trademark LIUDU Origin China HS Code 8479819000 Production Capacity 1000PCS/MonthProduct Description

Description of Automatic grommet eyelet machine

Main Parameters:

Voltage:220V

Rated Power:750W

Frequency:50HZ

Rotate Speed:3000-5000r/min

Punching speed:up to 120pcs per minute

Size:10mm,12mm,6mm (we can do the size that you need)

usage range:flex banners, x banner,advertising cloth,flag,

Feature of automatic eyelet machine

1.The machine can punch along the cloth freely in fast speed .

2.The eye button punched by this machine is very firm and hard to turn .

3.The guiding laser controls the distance between the eyebutton and ruler .

4.The flinging has no crevasses , which is very beautiful and impossible to fray the rope .

5.The pressing plate is designed by project plastic that couldn't get rusted or dirt the picture .

6.It is one of the necessary equipments for spray painting industry . Because of its advantages of labor saving , time saving and good punching quality

Details photo for eyelet puncher

Certificate of eyelet machine :

Why Choose Us

1. We are factory,Minimum 10% Lower price

2.Accept OEM

3.One year Free warranty

4.Fast delivery,Perfect after-sale service

5.The best safety welder supplier

6..All prototype products have to go through 4 checks in the whole process: Raw material inspection, In processing inspection,Final inspection,Outgoing inspection