High Speed Cardboard to Cardboard Laminator Machine (BKJ1307)

Tangshan Jiasun Import and Export Co., Ltd.- Type:Packaging Machine

- Driven Type:Electric

- Automatic Grade:Automatic

- Packaging Material:Iron Plate Wrapped with Plasti⪞ Film

- Packaging Type:Iron Plate Wrapped with Plasti⪞ Film

- Application:Cardboard Laminating

Base Info

- Model NO.:BKJ1307

- Max. Sheet Size:1270*720mm

- Min. Sheet Size:500mmx380mm

- Thickness of Upper Paper:100~800GSM

- Thickness of Bottom Paper:200~2000 GSM

- Max. Speed:150PCS,Min

- Lamination Precision:±0.5mmmm

- Total Weight:9000kg

- Total Length:10500kg

- Operation Space:3000X13500

- Power:3~380V(50Hz)

- Transport Package:Inron Plate Wrapped with Plastic Film

- Specification:CE, ISO 9001

- Trademark:JUXING

- Origin:China

- HS Code:8439300000

- Production Capacity:4 Sets,Month

Description

Basic Info.

Model NO. BKJ1307 Max. Sheet Size 1270*720mm Min. Sheet Size 500mmx380mm Thickness of Upper Paper 100~800GSM Thickness of Bottom Paper 200~2000 GSM Max. Speed 150PCS/Min Lamination Precision ±0.5mmmm Total Weight 9000kg Total Length 10500kg Operation Space 3000X13500 Power 3~380V(50Hz) Transport Package Inron Plate Wrapped with Plastic Film Specification CE, ISO 9001 Trademark JUXING Origin China HS Code 8439300000 Production Capacity 4 Sets/MonthProduct Description

Automatic Card To Card Lamination Machine

- Specifications

| Model | BKJ1307 | BKJ 1310 | BKJ 1410 |

| Max. Sheet Size (WxL) | 1270mmx720mm | 1270mmx1000mm | 1410mmx1410mm |

| Min. Sheet Size (WxL) | 500mmx380mm | 500mmx400mm | 500mmx400mm |

| Thickness of Upper Paper | 100~800gsm | 100~800gsm | 100~800gsm |

| Thickness of Bottom Paper | 200~2000gsm | 200~2000gsm | 200~2000gsm |

| Max. Speed | 150m/min | 120m/min | 120m/min |

| Lamination Precision | ±0.5mm | ±0.5mm | ±0.5mm |

| Total Weight | 9000kg | 9000kg | 11000kg |

| Total Length | 10500 | 10500 | 12000 |

| Operation Space | 3000x13500 | 3000x13500 | 3000x13500 |

| Power | 3~380V(50Hz) | 3~380V(50Hz) | 3~380V(50Hz) |

- Introduction of The Machine:

- Function of the machine: The machine can laminate card to card together to make tags, boxes etc.

- Structure:

Lower Feeder: 180-800 gsm paper

Compressor: Compress the laminated paper and conveying them to the piling part.

Paper piling part: To pile the laminated paper

Gluing Part: To glue on the bottom paper

Registration Part: To ensure precise paper lamination.

- Features By Part;

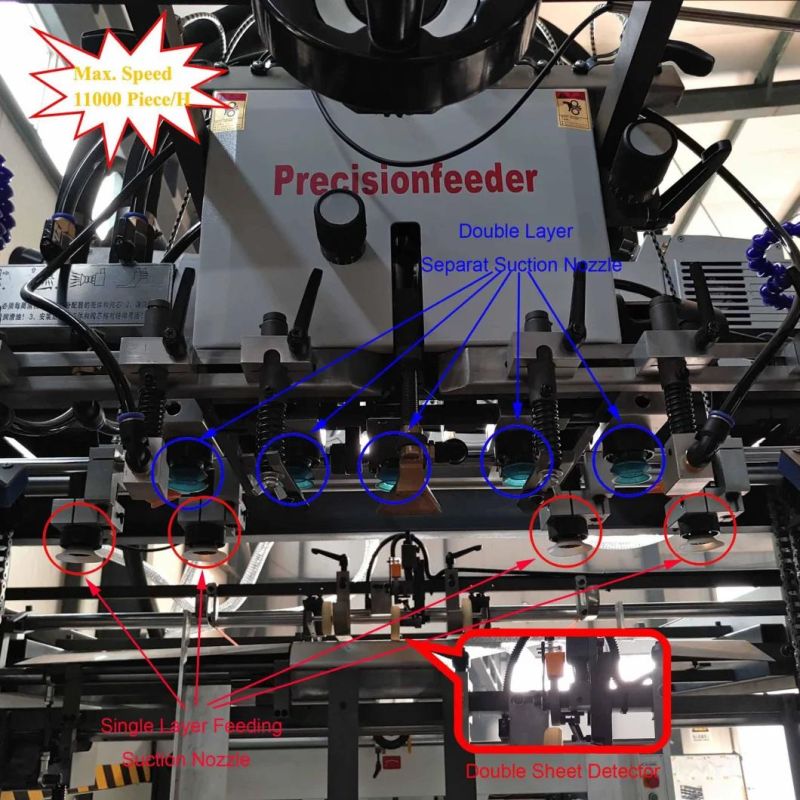

- The machine adopts mature high speed feeding structure with simple operation, easy maintenance which can fit to various kinds of paper.

- Four sucking and five forwarding which can do feeding of thin paper and wrapped paper.

- Double sucking rubber and single rubber forwarding which can avoid effectively double paper.

- Equipped with two blower to ensure paper separation smoothly.

- There are two side blowers as well. The position of the side blower can be adjusted to ensure the smooth feeding of paper

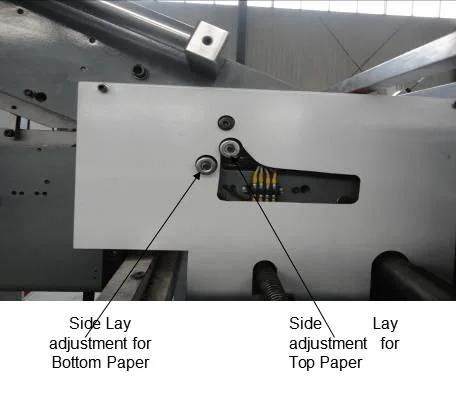

- Registration Adjustment:

- The operator can adjust the registration place of the paper either the wheel or by the fine adjustment handle to adjust the left and right position.

- For the in lamination, you can adjust the wheel according to the number it shows.

- The registration of lamination can be done when the paper is running. When fine adjustment is needed, you can only press related button to do the adjustment.

- The registration of the piling can be achieved by pressing the related buttons on the panel.

- Both of the pressure and glue volume adjust is easy by turning the adjustment wheel. You can record down the number in case you will have the same paper size.

- Three pressing belt to ensure smooth running of the paper

- Top and bottom front lay using chasing method to laminate the face paper and bottom paper.

- To protect paper roller with the roller, 6 anti-roll device is equipped with the machine.

- Two washing rollers are equipped with the machine, one is under gluing roller and one is under pressing roller to keep clean of the paper.

- Anilox roller makes the glue consumption even and less ( PVA is test for 30 gsm)

- Main bearings are NSK brand.

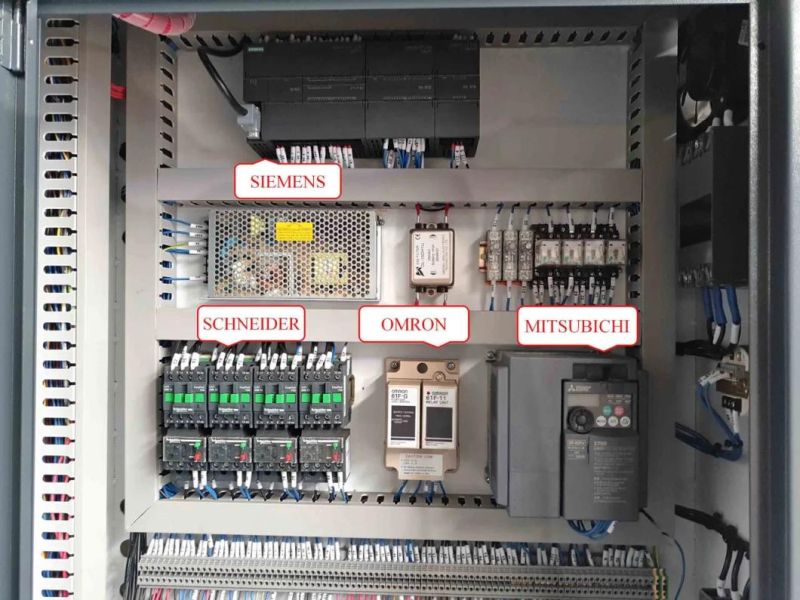

- Main electrical components are adopts famous brand, with features of long lifespan and good quality.