China High Speed Corrugated Laminating Machine (QTM1450)

Tangshan Jiasun Import and Export Co., Ltd.- Type:Roll Coater

- Driven Type:Electric

- Automatic Grade:Automatic

- Packaging Material:Metal

- Packaging Type:Pallet

- Application:Electronics

Base Info

- Model NO.:QTM1450

- High Speed:450mm Sheet Can Do 12000 Piece,Hour

- Glue Saving:Only 30g Per Square Meter

- Max. Sheet Size:1300*1300mm

- Min Sheet Size:500*440mm

- Face Paper Thickness:120-450GSM

- Bottom Paper Thickness:Acbef 3&5 Ply

- Transport Package:Steel Palte

- Specification:CE

- Trademark:Jiasun

- Origin:China

- HS Code:84393000

- Production Capacity:4 Sets,Month

Description

Basic Info.

Model NO. QTM1450 High Speed 450mm Sheet Can Do 12000 Piece/Hour Glue Saving Only 30g Per Square Meter Max. Sheet Size 1300*1300mm Min Sheet Size 500*440mm Face Paper Thickness 120-450GSM Bottom Paper Thickness Acbef 3&5 Ply Transport Package Steel Palte Specification CE Trademark Jiasun Origin China HS Code 84393000 Production Capacity 4 Sets/MonthProduct Description

High speed Automatic Flute Laminator- Specifications:

| Model | ―1300 | ―1450 | ―1650 |

| Max. Sheet Size | 1300mmx1300mm | 1450mmx1450mm | 1650mmx1600mm |

| Min. Sheet Size | 500mmx440mm | 500mmx440mm | 500mmx440mm |

| Thickness of face Paper | 120~450g/m2 | 120~450g/m2 | 120~450g/m2 |

| Thickness of Bottom Paper | ABCEF 3&5 Ply | ABCEF 3&5 Ply | ABCEF 3&5 Ply |

| Max. Speed | 153m/min | 153m/min | 153m/min |

| Laminating Precision | ±0.75mm | ±0.75mm | ±0.75mm |

| Total Weight | 8700kg | 9500kg | 10500kg |

| Total Length | 10700 mm | 12000 mm | 13000 mm |

| Operation Space (mm) | 3000x13500 | 3100x13500 | 3200x13500 |

| Power | 3~380V(50Hz) | 3~380V(50Hz) | 3~380V(50Hz) |

- Features of the machine:

- Key Points

- High Speed: It can run 12000 sheets per hours for sheet length 450mm.

- High Precision: At normal speed the precision can be controlled at ±1 mm with the yield 98%.

- Glue saving: It can be 30 grams of glue per square meter.

- General Introduction:

- Key Points

The machine adopts chasing registration method with the help of imported low-voltage parts, liquid sensor and motion control system.

- Machine Structure:

Bottom Feeding Part:Feed different kinds of corrugated sheet between ABCEF 3&5 Ply.

Conveyor:Press the laminated paper and convey to the paper delivery unit.

Gluing Part:Coating glue on the bottom paper.

- Features by Parts:

- Upper Feeding Part:

- High speed feeder with 3 sucking suckers and 4 delivery suckers with the highest speed 12000 sheets per hour.

- Double sucking rubber and single rubber forwarding which can avoid effectively double paper.

- There are two side blowers as well. The position of the side blower can be adjusted to ensure the smooth feeding of paper.

- Upper Feeding Part:

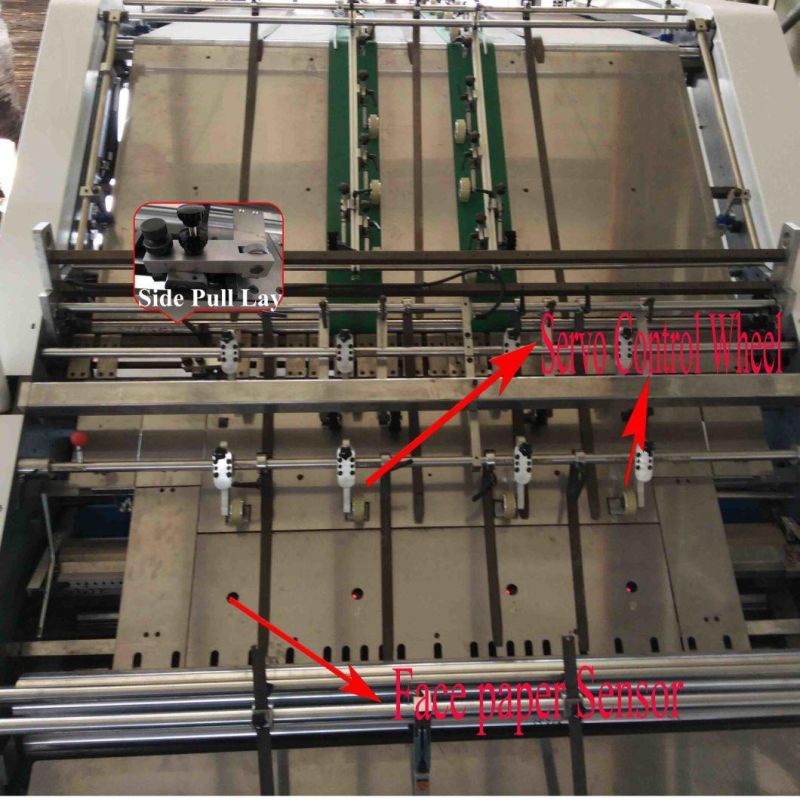

- Top Paper Conveying Part:

- Lay for the Pre-loading Paper Pile Part

- Side Lays of top paper to ensure the precision at side-way

Lays For bottom sheet

The adjustment of corrugated board includes side board adjustment front lay adjustment and paper frame adjustment.Side board and front lay can be adjust by manual and lock button based on paper size.

- When order is changed, the operator can do the order change easily by turning these wheels which makes the operation easy and fast. It also can control with hand wheel or the model of corrugated board.

- Automatic Glue Supply System: The machine adopts imported liquid level controller for glue supply. When detecting no glue in the glue barrel, it can stop the feeder automatically to avoid waste of paper.

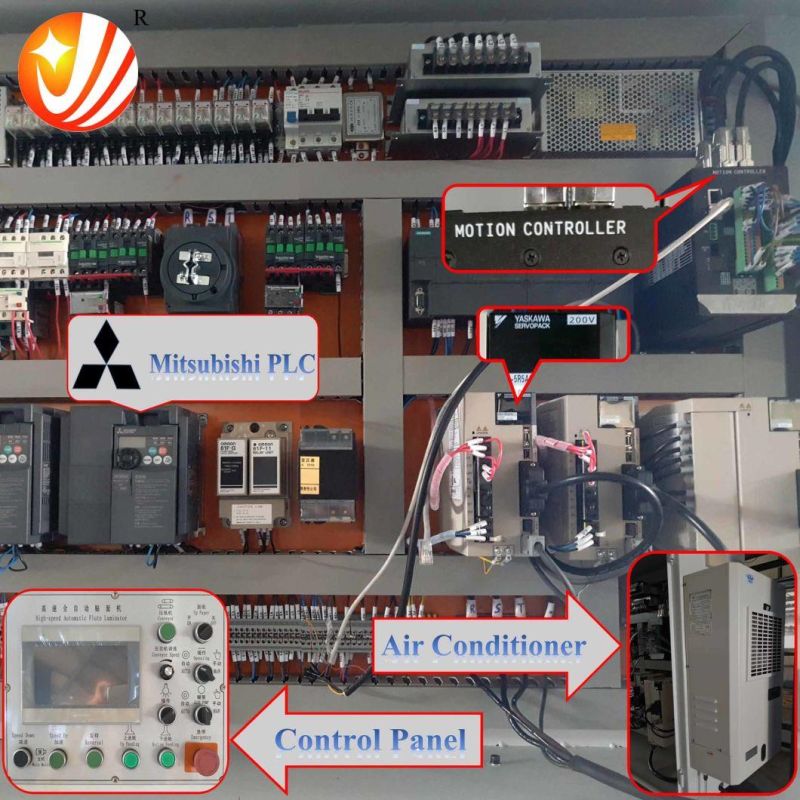

- Motion Control System: This machine adopts perfect combination of motion control system and servo system for better lamination precision. It only needs data input.

- The advantage of adopting motion control system is to keep face paper and bottom paper with good lamination precision.

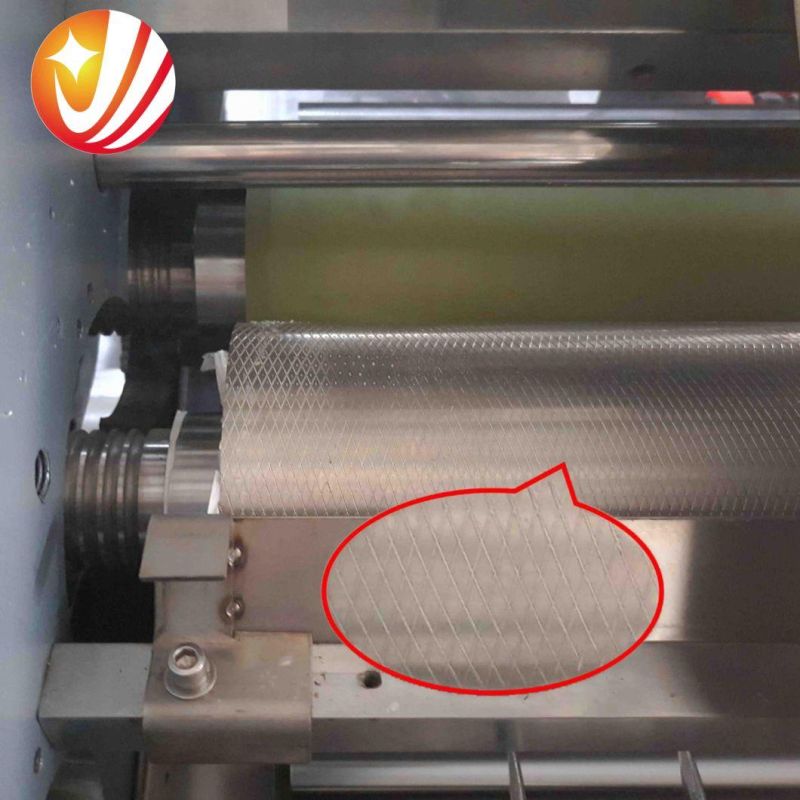

- Watering Roller: It can not only wash the dirt out of the bottom paper back, but also can pasting water on the bottom paper to make it soft and even to facilitate the lamination.

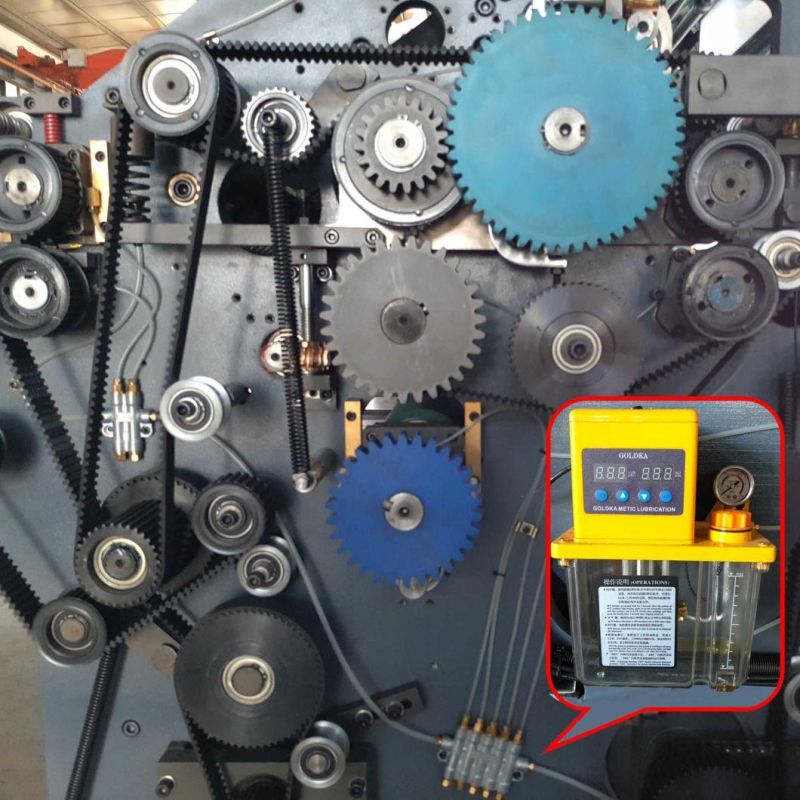

- Timing belt Transmission: Machine adopts timing belt transmission with stable running high precision and low noise.

- Front Lead Feeding Device: The bottom paper section adopts accurate vacuum feeding with big volume fan for better conveyor of curve paper. It is much better and convenient for five layer board stick. The servo motor control the red feeding wheel which makes the bottom paper run smoothly and accurately.

- The special parameters on the touch screen can be adjusted according to the paper type, for example, the distance of feeder lifting

- It is convenient when adjust the position of face paper and bottom paper. If you want to the face paper exceed the bottom paper 3mm, enter 3 on the screen. The data can not be changed when the machine speed is changing, the max data can be 30-40.,it can satisfy the demand of some special user.

- Configurations:

| Name | Brand |

| PLC | SIMENS S7-200 |

| Servo motor and controller | JAPAN YASKAWA |

| Touch screen | TAIWAN WEINVEW |

| Frequency transformer | JAPAN MITSUBISHI E740 |

| Photoelectric switch | SWITZERLAND BANMER |

| Contactor | FRENCH SCHNEIDER |

| Relays | JANPAN OMRON |

| Button | SHANHAI TIANYI |

| Glue liquid control | JAPAN OMRAN |

| Cog belt | TAIWAN SANWU |

| The key bearing | JAPAN NSK |

| Other Bearings | RENBEN BEARING |

| Main Power Motor | GERMANY SIMENS |

| Air Pump | Tai Wan Brand EUROVAC Rotary Vane Pump |