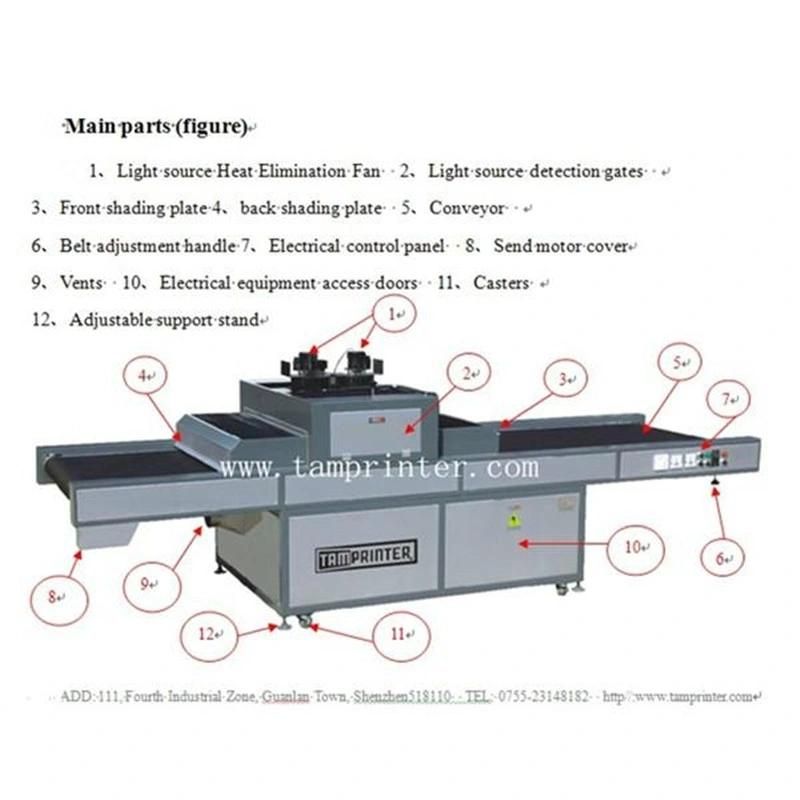

Screen Printing UV Drying Machine

Shenzhen Tamprinter Printing Machinery Co., Ltd.- Convey Belt Width(mm):730

- Effective Range (mm):750

- Max Thickness of Cured (mm):40

- Conveying Speed (M):2~20

- Power(P/V/Hz):3,380,50

- UV Lamp(Kw*PCS):5.6*2

Base Info

- Model NO.:TM-UV750

- Driving Power(W):90

- Total Power(Kw):12.1

- Size(L*W*H):2550*1050*1450

- Weight(Kg):350

- Transport Package:Plywood Case,Wooden Case,Carton,as Required

- Specification:CE; ISO9001-2000

- Trademark:tamprinter

- Origin:Shenzhen, Guangdong, China(Mainland)

- HS Code:8443198000

- Production Capacity:100sets,Month

Description

TM-UV750 UV curing machine 2.55m*1.05m*1.45m

Plywood 2.7m*1.2m*1.8m about 6m³

input 850+shade 200+tunnel 700+shade 200+output 550=2500mm

Distance from Handrail to ground 820mm

Distance from belt to ground 790~810mm can be adjusted

Belt 4900*730mm

Application:

It is apply to the special effects such as wrinkle, frosted refraction gem crystal and convex oil on the bullion paperboard, metal, glass, plastic, and also the UV curing of the offset printing ink on the offset press production.

Features:

1. With Teflon or stainless steel net, transmit speed steady and can be adjusted.

2. With two UV lighting tubes, can turn on the light according to the need.

3. Wink-dry make the surface of the stocks high hardness and rub resistance.

4. Tunneling-based make the whole machine light barrier good and without harm.

5. Equipped with powerful nether induced draughe system and big intake airway, can absorbs the stock on the mesh belthard. It can be used with production line and other equipment easily.

FAQ:

When machine in working have problem how to deal with it. Answer: Please sent us email first and tell us what the problem is. This is the standard machine, it's performance is very nice.

Even have question those will be below question. you can check first by yourself.

Q1, UV light can not light on.

A1: Check the electricity have connect in to machine. The indicator of power will showed red light. Than operate as manual showed.

Q2, UV light on, Belt stopped not run.

A2: Turn on the lamp quickly and waiting for machine power off automatically. (Our machine have function Only need turn off light the machine will turn off automatically.) Than Check the Motor of conveyor which under the unloading side of belt. If this question replace a new one. Check the Speed control: Change a new one if the new one worked. We will shipment a extra speed controller Marched with the machine when we package in each shipment.

Q3, The light twice again and gain than not light.

A3: Check your power supply is 220V +/_5% 50HZ, If Below 220V over the range of +/-5%, so keep your power supply steady. (our standard, any diffrent will be the machine we signed in purchase).

Q4, The light can not dry completely to product ( UV ink, UV glue,UV varnish, UV coating and so on)

A4: The lamp average lifetime is 800hours. if over this pls replace a new one. (We suggest when you purchase our UV machine, also purchase a new extra lamps as replacement) If a new lamp, than check the ignitor, transformer, and lamp they connect line is well connected. Especially the lamp line. there is screw in, if it is loosen. pls stick it lightly.

If find any parts need replacement , than within one year Guarantee we supply by free.

Also you can purchase a new one out of Guarantee.

We supply all parts of our machine. including: UV lamp, Transformer, Capacitor, Trigger, ignitor, reflector, Quartz, adapter, Phase protector, speed control, Speed motor, Exhausting fun, Air out tube ......

Welcome to contact us if any question.

About Us:

Tamprinter printing machinery group limited is one of the most professional special printer supplier of Plastic Field in China. We have supplied OEM service for the domestic counterparts since 2005. OEM products have been achieved CE certification.

Due to business expansion, Shenzhen Tamprinter printing machinery limited International trade department have been separated from the parent company in March 2013.

Key products: Pad printer, Screen printer, UV curing machine, Heat transfer machine.

Applications :

It mainly applies to the printing process and pre-postpress of plastic and hardware products .Our equipment is also applicable to other material as glass, ceramic, wood, leather, cloth, etc.