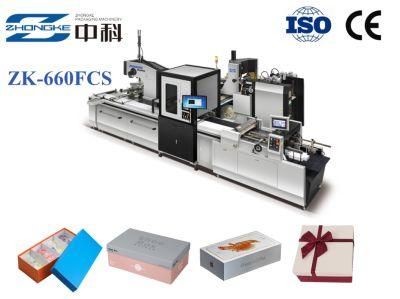

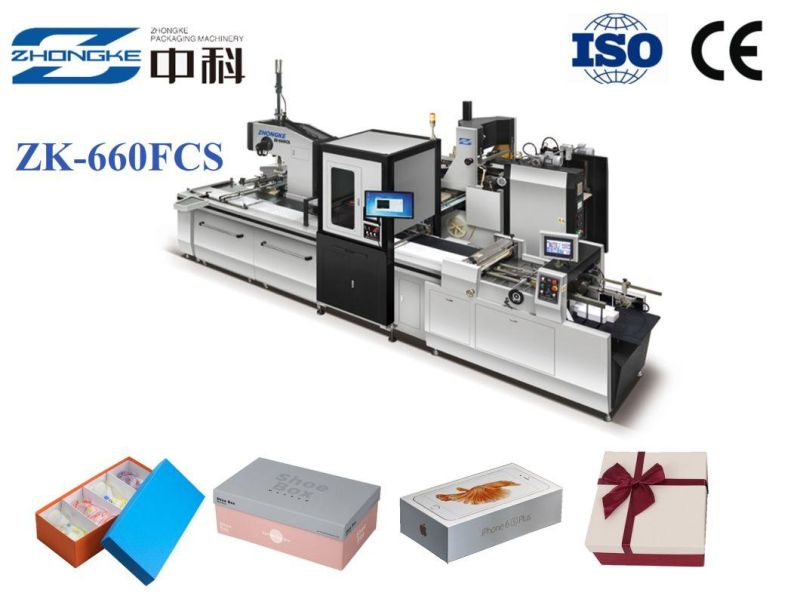

- Model NO.:ZK-660FCS

- Cover Paper Length Available:190-660mm

- Cover Paper Width Available:155-560 mm

- Precision Error:+-0.05mm

- Electrical Power:38kw

- Material Thickness:0.8-3mm

- Max Box Length:400 mm

- Max Box Width:300 mm

- Max Box Height:125 mm

- Computerized:Yes

- Machinenet Weight:8100kgs

- Air Supply:410L,Min 0.6MPa

- Transport Package:Wooden Pallet

- Specification:CE, ISO9001; 2000

- Trademark:ZHONGKE

- Origin:Zhejiang, China

- HS Code:84414000

- Production Capacity:15-20sets,Month

Basic Info.

Model NO.

ZK-660FCS

Cover Paper Length Available

190-660mm

Cover Paper Width Available

155-560 mm

Precision Error

+-0.05mm

Electrical Power

38kw

Material Thickness

0.8-3mm

Max Box Length

400 mm

Max Box Width

300 mm

Max Box Height

125 mm

Computerized

Yes

Machinenet Weight

8100kgs

Air Supply

410L/Min 0.6MPa

Transport Package

Wooden Pallet

Specification

CE, ISO9001; 2000

Trademark

ZHONGKE

Origin

Zhejiang, China

HS Code

84414000

Production Capacity

15-20sets/Month

Product Description

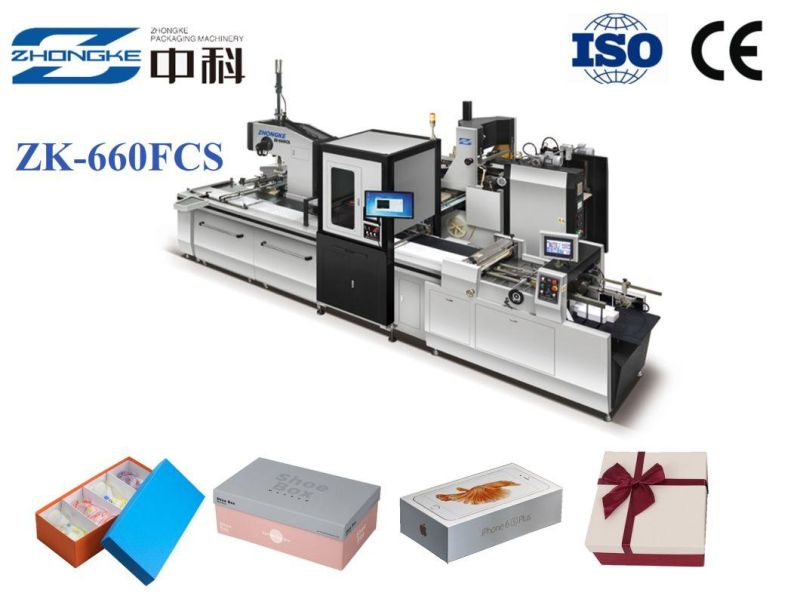

ZK-660FCS Automatic Rigid Box Making Machine

Machine Instruction

This machine using motion controller system,visual manipulator system and touch screen man machine interface system.which achieve automatic paper feeding gluing,cardboard four corner taping ,position,feeding,edge covering ,full ear folding,forming and shaping of finished box.whole operations are full automatic.

It is applicable to the production of high-end rigid boxes, such as business package boxes

for electronic products, mobile phone boxes, jewelry boxes, gift boxes, cosmetics boxes, watch box and so on.

Machine Features

1. Suitable for all kinds of automatic rigid box production line.

2. The whole machine adopts the control system of the motion controller,and touch screen man -machine interface control system

3. Visual manipulator positioning( error±0.05)

4.Automatic box lifting and conveying device automatic suction and conveying of paper and cardboard

5. 24-hour control glue preheating function,glue viscosity automatic control system

6. Taping machine using separate man-machine interface control system

7. Electronic cam and mechanical cam combine to pay their respective advantages

8. Full computer function parameter setting and fault alarm function

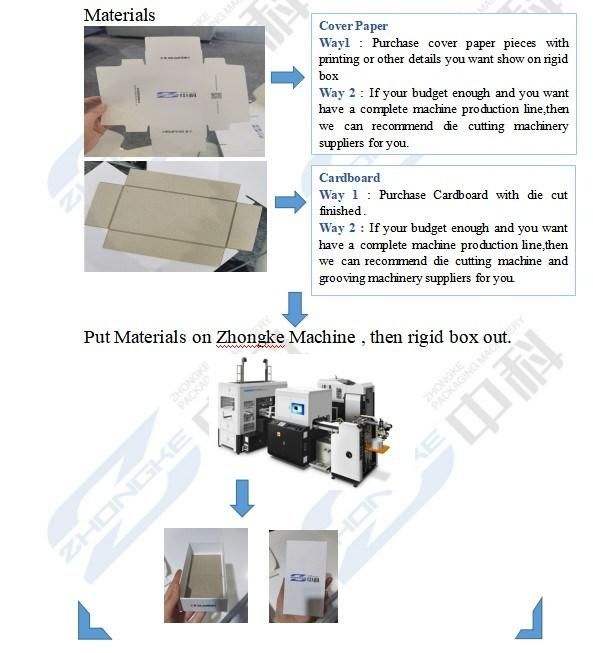

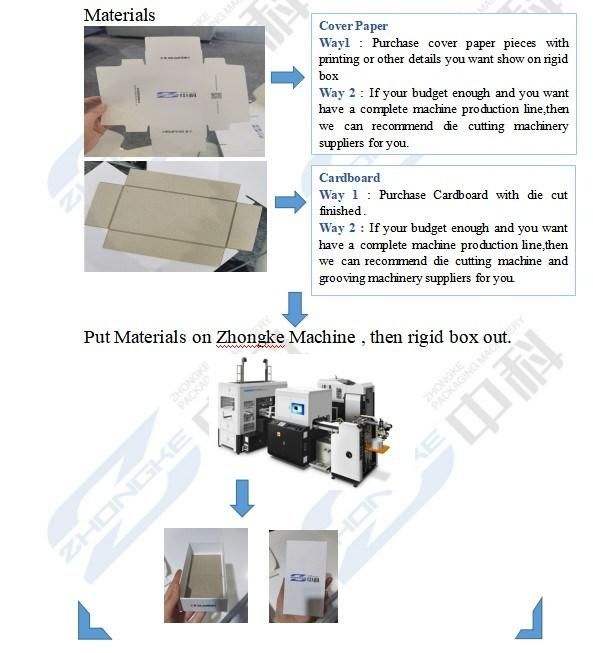

About Raw Material Preparations

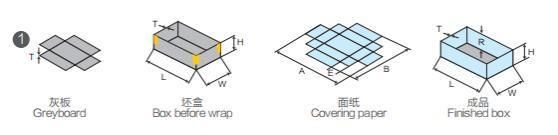

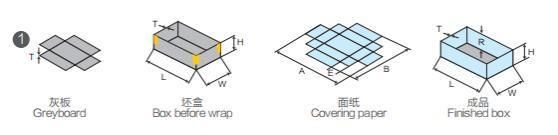

About Box Forming In Our Rigid Box Making Machine

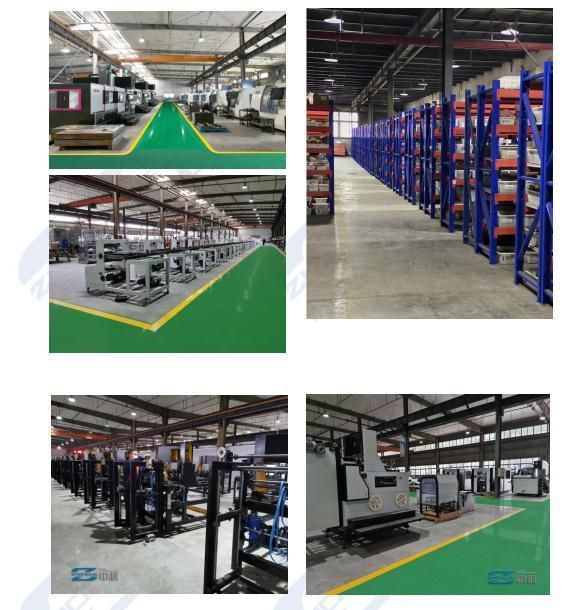

About Zhongke

Wenzhou Zhongke Packaging Machinery Co., Ltd. was established in 2002. It is the first leading enterprise in China to independently develop and create a series of automatic rigid box making machines. Founded the two major brands of "ZHONGKE" and "HEWANG Box King"

It is located in Zhejiang Province, covering an area of 100,000. It is a private economic entity integrating independent research and development, design, production, sales and service. On the basis of drawing on the advanced technology of similar foreign products, the company cooperates with well-known domestic universities to develop intelligent automatic rigid box making machines. Its technical department is at the domestic leading level, and many have filled the domestic gap, optimizing and upgrading the traditional industry. Promoted the development of China's packaging industry.

fter 20 years of development, the company has established perfect sales network and integrated after-sale service system at domestic and abroad, which enables the company to provide timely, accurate and efficient services, and won good customer reputations. The products are sold all over in China and exported to more than 100countries and regions such as Europe, America, Southeast Asia, South America, Middle East and Africa. The production, sales volume and scale are all ranked first in the same industry.

For the future development, we will continue to focus on the "Safe, high-quality, efficient and intelligent" project, which will be specialized, refined, strong and long-lasting. Adhering to the customer's needs as the core, we are committed to providing high-tech, high-quality rigid box technology solutions, which will drive the development of the packaging industry.

Zhongke Warehouse

Packing And Container Loading

Unforgettable Moments With Customers

More Details, Welcome Your Inquiries, Lets Find Out Togather!