UV Coating Machine for Spc Flooring Production Line

Romeroca Industry Co., Limited- After-sales Service:on-Site Installation, Commissioning, Technical Sup

- Warranty:12 Months

- Type:Roll Coater

- Driven Type:Electric

- Automatic Grade:Automatic

- Application:Producing Spc Flooring

Base Info

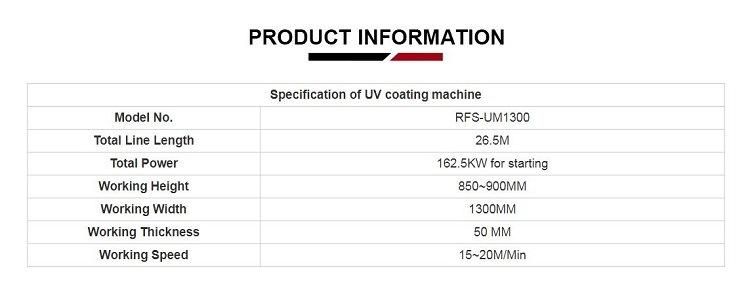

- Model NO.:RFS-UM1300

- Transport Package:Pallet

- Trademark:Romeroca

- Origin:China

- Production Capacity:10 Sets, Month

Description

Basic Info.

Model NO. RFS-UM1300 Transport Package Pallet Trademark Romeroca Origin China Production Capacity 10 Sets/ MonthProduct Description

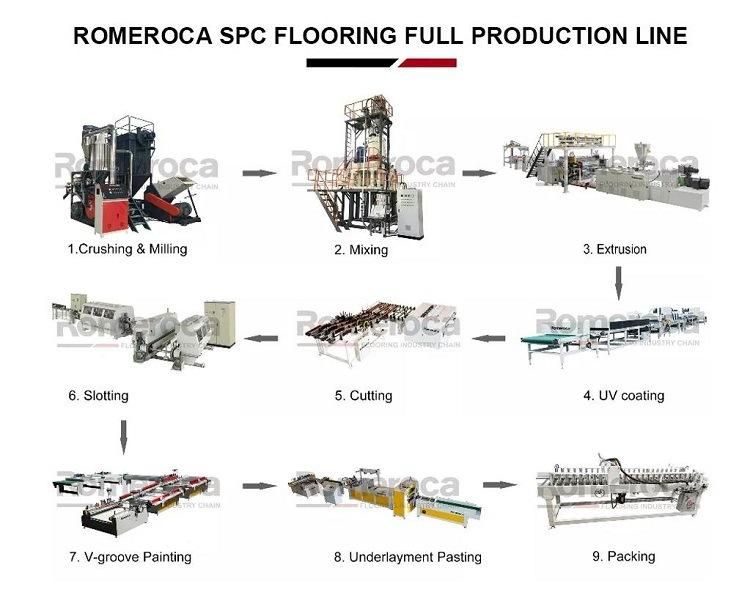

Romeroca SPC Flooring UV Coating Machine is used to coat UV paint on the surface of SPC board. It can help to keep the glossy uniform and improve the scratch resistance of the surface.

Romeroca SPC Flooring UV Coating Machine is used to coat UV paint on the surface of SPC board. It can help to keep the glossy uniform and improve the scratch resistance of the surface.UV coating directly affects the wear resistance and scratch resistance of the SPC flooring products.

Advantages of Romeroca UV coating Machine:

Romeroca SPC flooring UV coating line is energy-saving, efficient and stable. The roller coater is divided into three sections. The whole machine has 3 sets of motor groups independently controlled, convenient operation and maintenance, high safety factor, and good effect during the coating process. UV dryer can be equipped with electronic variable control system/UV-LED cold light source, power dryer, paint film drying effect is more perfect.

| 1) 12-months warranty on all machine products (non-consumable parts). |

| 2) 36-months tracking service, prompt response within 24 hours. |

| 3) Provide factory production process and machine layout design. |

| 4) Provide technical guidance, training and support. |

| 5) Provide timely supply support for spare parts. |

| 6) Other support from raw materials, machines to finished products. |