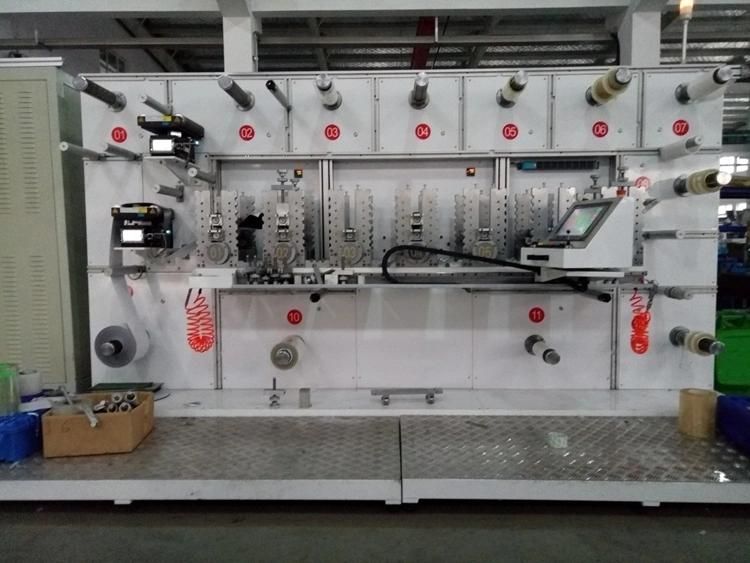

Silicon 3m Adhesive Tape 5 Stations Rotary Die Cutting Machine

Chuan Zhen Precision Machinery (Suzhou) Co., Ltd.- After-sales Service:Staff Training and Installation Guide

- Warranty:One Year

- Species:Rotary Die-Cutting Machine

- Imprinting Type:Rotary

- Placing Form of Template:Horizontal

- Die Cutting Tool:Metal Mold

Base Info

- Model NO.:MQ-R-5

- Computerized:Computerized

- Automatic Grade:Automatic

- Application:Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials

- Driven Type:Electric

- Driven System:Servo Motor

- Station:5 Stations

- Certification:CE ISO

- Transport Package:Wooden Case

- Trademark:chuanri

- Origin:China

- HS Code:8411100000

- Production Capacity:200 Sets,Month

Description

Basic Info.

Model NO. MQ-R-5 Computerized Computerized Automatic Grade Automatic Application Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials Driven Type Electric Driven System Servo Motor Station 5 Stations Certification CE ISO Transport Package Wooden Case Trademark chuanri Origin China HS Code 8411100000 Production Capacity 200 Sets/MonthProduct Description

Silicon 3M Adhesive Tape 5 Stations Rotary Die Cutting MachineScope applicable:

It is suitable various material, double stick tape, one side tape, non-adhesive label, bubble cotton, protection film, metal foil etc. It is suitable for process of profession products, such as electronics, vehicle, medical treatment and printing etc. Multiple layout material precision compound, the shape and structure complications product can be processed into model at a time.

Functional characteristics:

A: Speed 0-50 m/min, max width of original material 160 mm.

B: Each work station unit equipped with separated servo electrical engineering drive.

C: PLC and profession sport controller with multiple stalks, touching interface

D: Each winding and rewinding system with separated serve motor drive.

E: Each winding and rewinding tension controlled by automatic control consistent tension controller.

F: Multiple molding tool sets harmonized, automatic and handle mode.

G: CCD on-line examination system (choosing installation)

H: Original material rewinding automatic deviation-correcting system.

Main devices:

1. 5 sets of work station is.

2. The work station main drive electrical engineering and 5 sets of servo motor.

3. 14 sets of winding/rewinding system, 14 sets winding/rewinding of servo motors 14 sets of tension controller.

4. 10.4 inch color touching interface

5. 1 set of rewinding automatic deviation-correcting system.