Paper Coating Machine for Thermal Paper, POS Paper, ATM Paper

QINGDAO JIERUIXIN MACHINERY AND TECHNOLOGY CO., LTD.- Type:Blade Coater

- Driven Type:Electric

- Automatic Grade:Automatic

- Packaging Material:Wood

- Packaging Type:Case

- Application:Thermal Paper,POS Paper,ATM Paper Making

Base Info

- Model NO.:JRX

- Customized:Customized

- Certification:Ce,ISO

- Paper Type:Thermal Paper

- Coating Type:Three-Roller Type Back Coater

- Machine Wide:2200mm

- Machine Speed:300m,Min

- Transport Package:Wooden Case

- Trademark:JRX

- Origin:China

- Production Capacity:60sets,Year

Description

Basic Info.

Model NO. JRX Customized Customized Certification Ce,ISO Paper Type Thermal Paper Coating Type Three-Roller Type Back Coater Machine Wide 2200mm Machine Speed 300m/Min Transport Package Wooden Case Trademark JRX Origin China Production Capacity 60sets/YearProduct Description

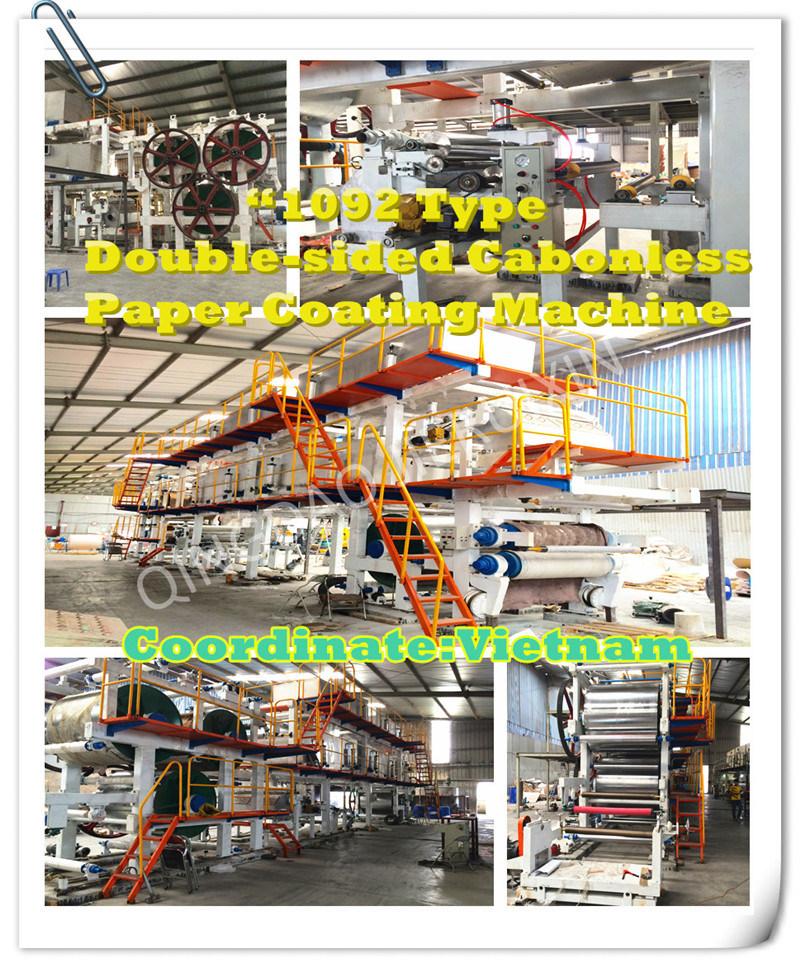

Paper Coating Machine for Thermal Paper,POS Paper,ATM Paper

1.Overview:

Our thermal paper coating machine mainly include single-station release paper unit, blade coating, pneumatic open type hot air drying system, back coating wet Mizube, *dryer coherent states finishing department, two roll calender machines, single station automatic correction reel,drive unit and electrical control nine parts. Drives with frequency step motor drive. The machine has a simple structure, easy operation and maintenance, loss of paper rate, etc.

2.Main Technical Parameters:

Paper types: thermal paper(three proofing)

Base weight: 40-100 g/m²

Operating Speed: 250-300 m / min

Designed speed: 350 m / min

Coating weight: 1-10 g/m² per coater

Coating type: blade knife

three-roller type back coater

Roller surface width: 2400mm

Tracks width: 2900mm

Compressed air pressure: 0.5-0.6 Mpa

Saturated steam pressure: 0.2-0.4 Mpa

Drying type: hot air blowing

Finishing type: hot cylinders and cool cylinders

Total power of Main frame: 116KW (excluding paint preparation system, paper rewinding and others)

Maximum dimensions: length 61300mm, width 12000mm, height 5000mm

3.Process:

unwinding roll - scrape-knife coating device - three drying ovens (four meters each drying oven) -scrape-knife coating device - four drying ovens (four meters each drying oven) -back wet device -3-1350 debugging mode Cylinder dryer-two roll calender machines -level rewinding roll device, please see process flow diagram

4.Hot air drying system:

*This machine adopts three 4 m hot air oven, oven a total length of 12 meters. The system includes hot air oven, heating fans, heat exchangers, thermometer and hot air ducts.

*Heat oven to pneumatic open type oven, oven body is made of welded steel , insulation thickness of 80 mm , box packaging material selection, color steel plate,galvanized sheet inside the package chosen . Hot air nozzle is stainless steel making . Each oven is equipped with four guide rollers ,guide rollers with gear .

*Air within the oven through the fan recycling, and add fresh air , the temperature of the air in the heat exchanger by regulating the steam pressure control .

Our Survice

♦. Reasonable suggestions for selection of equipment

♦. Provide detailed description and assembly drawing , to make you more aware of the device's ability to work

♦. Engineers on-site equipment installation and commissioning

♦. Train and teach your worker to operate the paper machine

♦. Professional technical guidance and technical support during your production, make sure the device's work properly and production

♦. Equipment modification and updating

♦. We will testing installation machine in the factory workshop , to ensure safety and quality

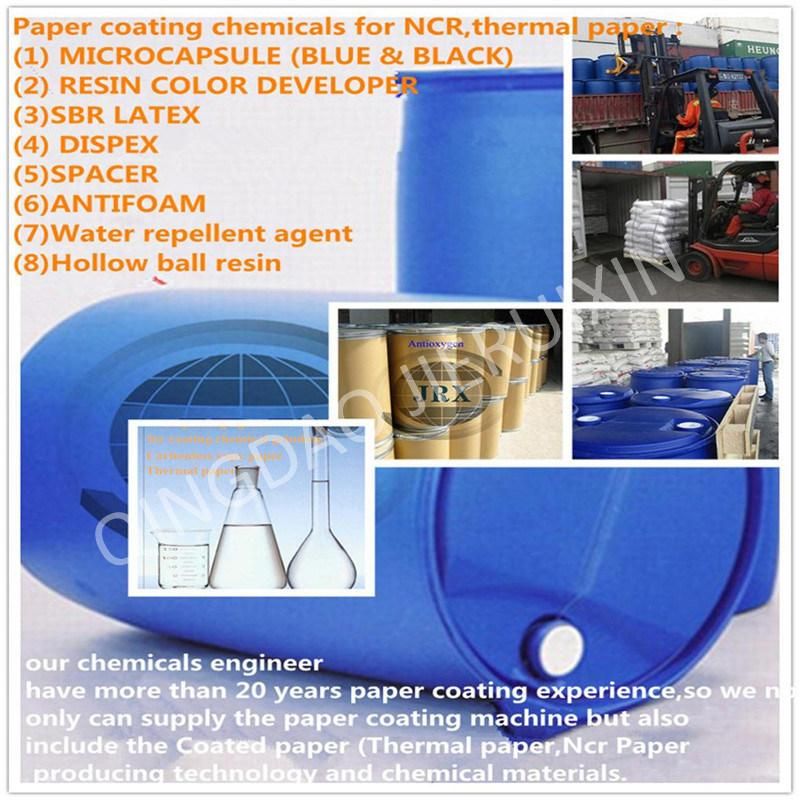

♦. Supply Carbonless paper and Paper coating chemicals ,formulation ,technology and other suggestion to customers.

♦. After-sales service for one year: equipment maintenance guidance

♦. Provide Turnkey projects

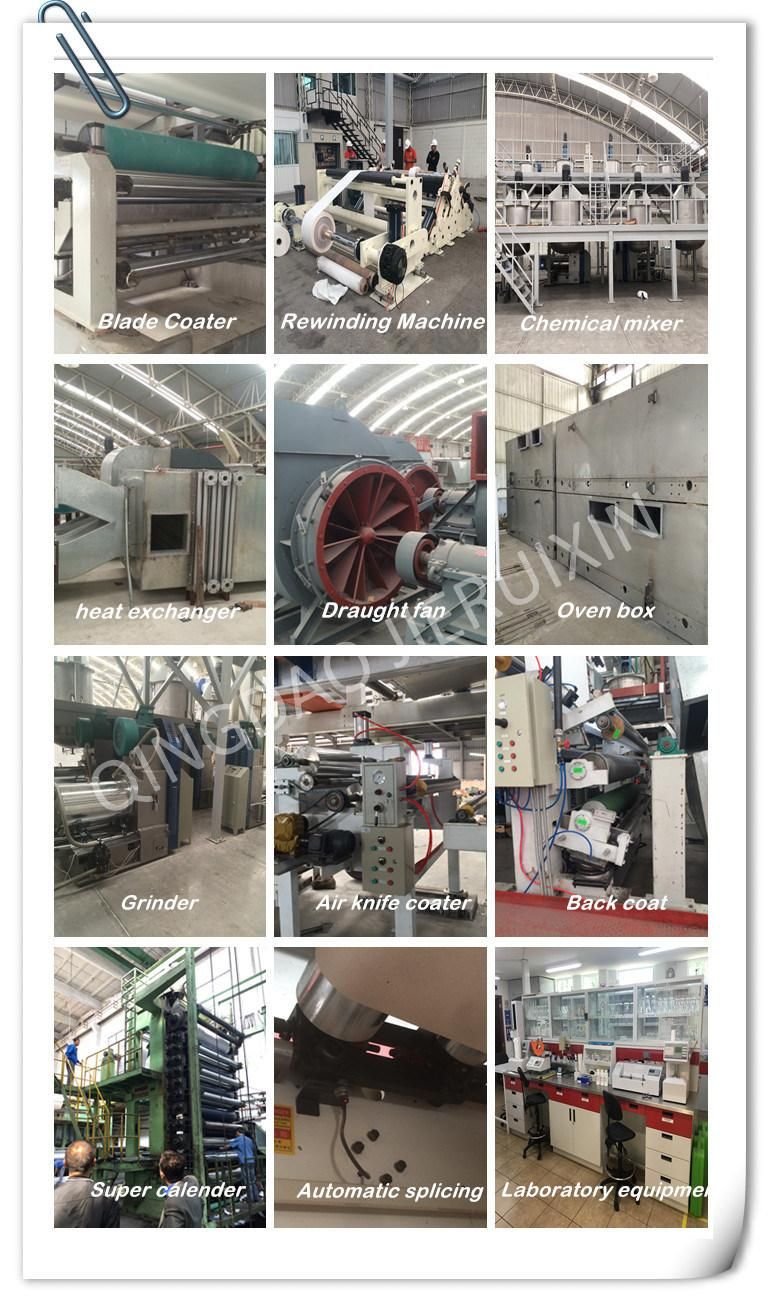

These are our Paper making machine.

These are our equipment accessory and machine parts as follows, meeting your needs is our belief, best service for you is our pleasure.

we have our own chemist and prefer to supply chemical ,formulation ,technology and other suggestion to customers.Then our formulation will match our machines ,and get the best quality paper for them.

Our Trade Shows

My Message