High Quality Manual & Automatic Feeder Feeding Die Cutting and Creasing Machine Corrugated Carton Box Making Machine

DONGGUANG XINGLONG PACKAGING MACHINERY CO., LTD.- Species:Die Cutting and Creasing Machine

- Imprinting Type:Platen

- Placing Form of Template:Horizontal

- Die Cutting Tool:Steel Blade

- Computerized:Computerized

- Automatic Grade:Semi-Automatic

Base Info

- Model NO.:MY-1300

- Application:Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials, Earthquake Products

- Model:My-1300

- Die Cutting Way:Platen Press

- Max Paper Transmitting Size:1320*940mm

- Min Paper Transmitting Size:400*500mm

- Max Die Cutting Size:1300*920mm

- Min Gripper Size:6mm

- Max Die Cutting Pressure:320n,Cm*Cm

- Die Cutting Precision:+-0.1mm

- Voltage:380V

- Certification:Ce, ISO9001:2008

- Warranty:1year

- Max Die Cutting Speed:4500 Sheets,H

- Total Power:20.5kw

- Total Weight:17.5t

- Overall Size:6200*2200*2250mm (Not Including The Pedal)

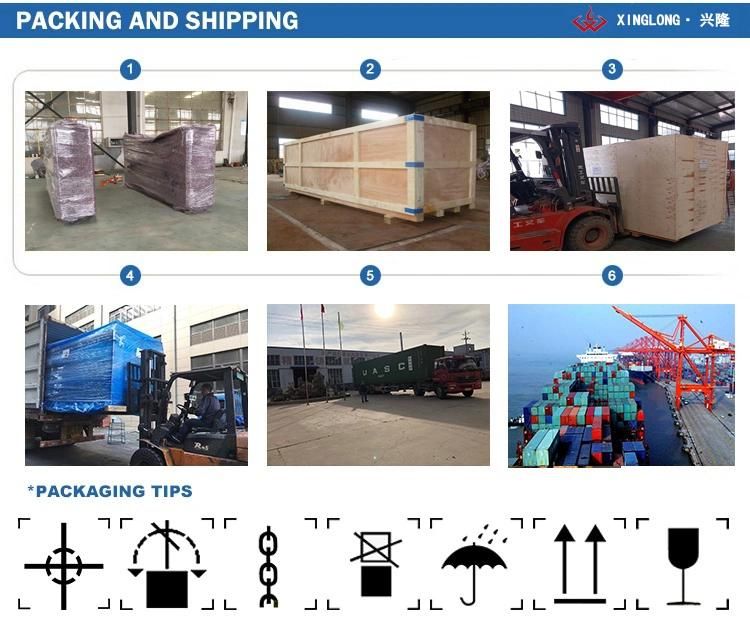

- Transport Package:Wodden Case, Container

- Specification:1300

- Trademark:XINGLONG

- Origin:Hebei, China

- HS Code:8501109901

- Production Capacity:1set,Month

Description

Machine Introduction: The MY-1300 Manual & Automatic Die Cutting and Creasing Machine is the main equipment for making high-grade color box, plug and different shapes of ink cartons. The machine adopts Anchuan servo system, Gogol four axes motion controller, non-pressure feeding system, high strength gripper teeth row, whole swing front guide, automatic pushing guide, high precision interval structure, pneumatic locking plate. Pneumatic clutch, overload protector, automatic paper collecting, makes our machine has a short paper feeding distance, positioning correctly, paper collecting in order, can also do non-gripper die cutting. Computer control makes the whole machine running automatically, man-machine interface display the working condition and trouble dealing method. Key components, control systems and fasteners are imported and carefully assembled to ensure the safety and reliability of the machine. With many sensors and protection devices to ensure machine working and workers safety.

Components and Features:

1. Paper feeding part:Feeder feeding can process the products such as E flute, card paper, hand bag, leather, plastic and so on. While the Manual Feeding can process B flute, 3 ply, 5 ply and 7 ply corrugated paper and the paperboard with camber.

2. Positioning part: the front guide, the side guide.

3. Die cutting part: grippers, die cutting sheet frame, die cutting steel plate, transmission structure, host bottom platform, the moving platform and the upper platform, intermittent structure, pneumatic clutch brake.

4. Paper collecting part: Collecting paper automatically and quantitatively.

5. Electric control part: Motor, PLC and man-machine interface, electronic control system, all kinds of safety protection device.

6. Lubrication system: Forced lubrication system and timing lubrication system.

FAQ:

1. Q: Are you a manufacturer, trading company or a third party?

A: We are a manufacturer, located in Mahai industrial area south of Dongguang county, Hebei province, China. Warmly welcome to visit our company.

2. Q: How does your factory do regarding quality controlling?

A: 1) All raw material we used are environmental-friendly

2) Skillful workers care every details in handling the producing and packing process

3) Quality control department are specially responsible for quality in each process

We have been kept providing high quality products by introducing advanced technologies for over 20 years, and our products are also widely exported to many different countries including Russia, the Middle East, Africa, Southeast Asia, EU, etc, which earned us a high reputation among the customers.

3. Q: What is the payment terms?

A: T/T, it is 30% deposit due at placing order and 70% balance due before loading.

4. Q: How about the after-sale service?

A: 1) TM online for 24 hours, also contact by email, skype, MSN, whatsapp, etc.

2) To solve the problems with videos/pictures.

3) One year warranty for spare parts change.