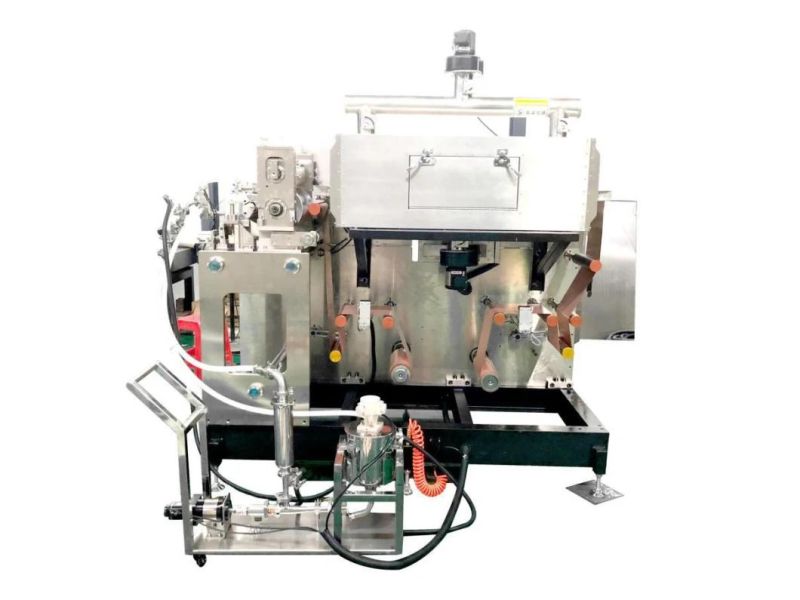

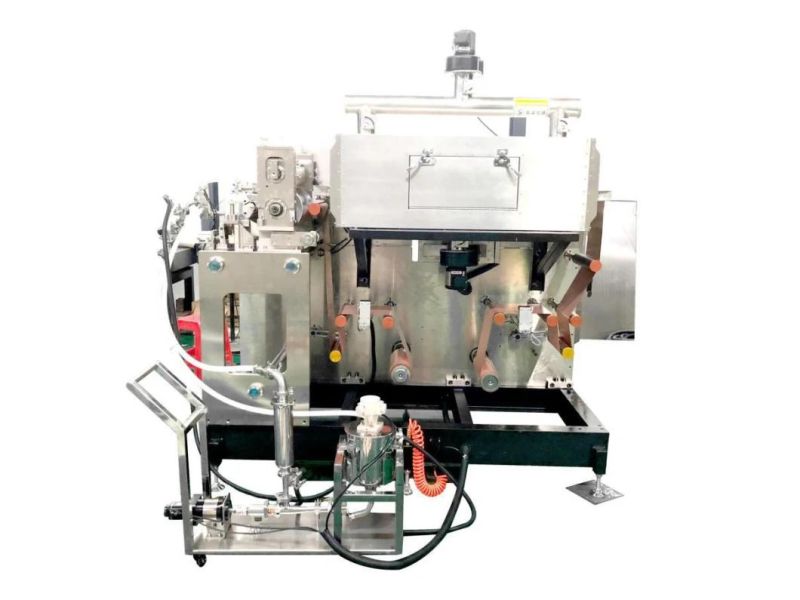

Precision Slurry Feeding Pump Battery Equipment Lab Slot Die Coating Machine for Lab Research Gn-360s

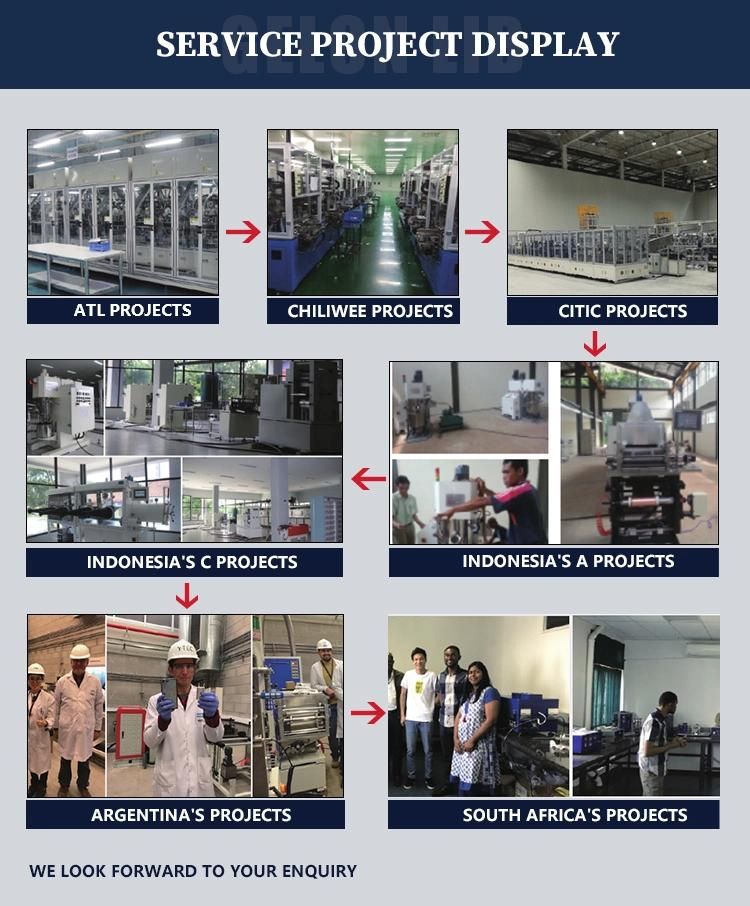

Shandong Gelon Lib Co., Ltd.- After-sales Service:Online

- Warranty:1 Year

- Type:Blade Coater

- Driven Type:Electric

- Automatic Grade:Automatic

- Packaging Material:Metal

Base Info

- Model NO.:GN-360S

- Packaging Type:Battery

- Application:Electronics, Battery

- Coating Width:< 300mm

- Baseband Material:Copper Foil, Aluminum Foil, etc

- Coating Methode:Slot Die Coating

- Baseline Width:100-320mm

- Mechanical Strip:0.5-7m , Min

- Coating Speed:0.5-1.5m,Min

- Oven Length:1.5-2m

- Transport Package:Wooden Box

- Specification:different size

- Trademark:GELON

- Origin:China

- Production Capacity:20sets,Month

Description

Overview

Solid content (t%) (38~80±3) (35~65±3)

Proportion of slurry(g/cm3)

1.5~3.0

1.0~2.0Viscosity(cps) 2000~20000 1000~10000 Binder PVDF/Water-based PVDF/SBR

Intermittence coating or continuous coatingDensity of one side

coated surface (g/m2) 35~300 35~300

Product Description

Detailed Photos

Product Parameters

NMP(Oily/DI-water( Water-based)Proportion of slurry(g/cm3)

1.5~3.0

1.0~2.0

Intermittence coating or continuous coating

coated surface (g/m2)

- Machine Parameters

| Roll width | 500 mm |

| Effective coating width | <380mm |

| Weight range of single coated film | 35~300g/m2 |

Power supply | 380V x 50Hz,3 phase (control power supply 220 V x 50Hz, single phase) voltage fluctuation range 10%~-10% voltage fluctuation range |

Total power | Maximum 15KW (When electric heating, the normal working power is about 40% of the maximum starting power.) Control heating with a power amplifier. |

Gas source | 0.6MPa~0.8MPa, air pressure fluctuation ±1%(clean air after water removal, no oil, filtration, steady pressure, )compressed air consumption 0.5 m3/h; compressed air is divided into two ways one for coating valve, equipped with special gas storage tank (0.3 m3/h), the other way to feed pressure belt cylinder, clamping cylinder and so on (0.2 m3/h). |

| Appearance Color | Nickel plated nose, box part stainless steel, black or customer specified |

| Ground requirements | The foundation is cement ground or terrazzo ground, flatness ±5 mm/m2, bearing capacity 1500kg/m2 |

| Coating Part temperature | 23 ± 4ºC |

| Coating part humidity | 45%RH (No condensation) |

- Oven Partial Parameters

| Air duct structure | Upper and lower air ducts |

| Drying oven | 1 ovens |

| Total oven length | 2m |

| Single oven length | 2m |

| Oven heat source | Electric heating, hot air circulation structure |

| Single oven heating power | 10KW/2m |

| Oven temperature | Max150ºC, temperature difference Max150ºC±5ºC in single oven |

| Blow mode | A hot fan provides air |

| Air circulation mode | Independent air volume control, up and down air volume through the valve control |

| Surface temperature outside the box | ≤50ºC |

| Oven materials | Stainless steel, inner tank (SUS304 :1.0mm), housing (SUS201 :2.0mm) |