High Speed Paper Cup Fan Roll Paper Metal Die Punching Machine 400 Strokes/Min

Zhejiang Feida Machinery Co., Ltd.- Species:Metal Die Punching Machine

- Imprinting Type:Platen

- Placing Form of Template:Vertical

- Die Cutting Tool:Metal Mold

- Computerized:Computerized

- Automatic Grade:Automatic

Base Info

- Model NO.:FDC850,920,1000,1200

- Application:Printing and Packaging

- Weight:3.5t

- Max Roller Diameter:1500mm

- Total Power:10kw

- Air Pressure Consumption:0.25m3,Min

- Paper Gram Weight :150-350GSM

- Cutting Precision:0.2mm

- Transport Package:Wooden Packaging

- Specification:14CMB

- Trademark:FEIDA

- Origin:China,Wenzhou

- HS Code:844110000

- Production Capacity:200 Sets Per Year

Description

Basic Info.

Model NO. FDC850/920/1000/1200 Application Printing and Packaging Weight 3.5t Max Roller Diameter 1500mm Total Power 10kw Air Pressure Consumption 0.25m3/Min Paper Gram Weight 150-350GSM Cutting Precision 0.2mm Transport Package Wooden Packaging Specification 14CMB Trademark FEIDA Origin China/Wenzhou HS Code 844110000 Production Capacity 200 Sets Per YearProduct Description

| Model | FDC850 |

| Max Paper Width | 850mm |

| Cutting Precision | 0.20mm |

| Paper Gram Weight | 150-350g/m2 |

| Production Capacity | 300-380times/min |

| Air Pressure Requirement | 0.5Mpa |

| Air Pressure Consumption | 0.25m³/min |

| Weight | 3.5T |

| Max Roller Diameter | 1500 |

| Total Power | 10KW |

| Dimension | 3500x1700x1800mm |

Introduction:

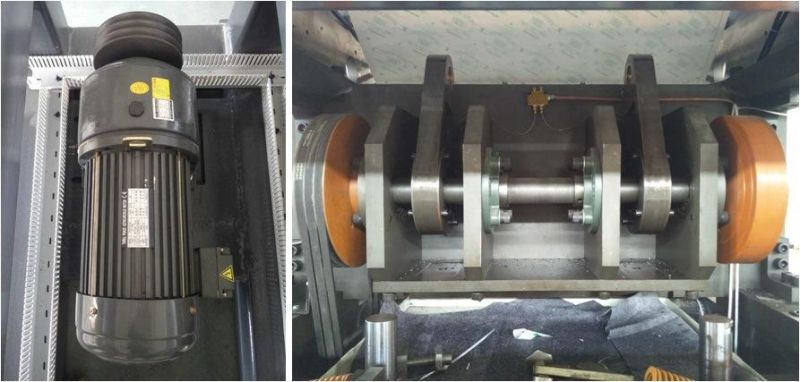

FDC series automatic roll punching machine based on international advanced technology, it's widely used in paper cup fan products. It adopts micro-computer, human-computer control interface, servo positioning, alternating current frequency converter, photoelectric correcting deviation system, centralized oil lubrication.

1. It adopts micro-computer, human-computer control interface, servo positioning, and we make the wallboard, base much stronger than others, it guarantees that when the machine runs with 300 strokes/min, you won't feel that machine is shaking.

2.Lubri cation System: Adopts forced lubrication system to ensure main driving oil supply regularly and reduce friction and prolong the machine life, you could set it to lubricate one time every 10 minutes.

3.The die-cutting force is provided by a 5.5KW inverter motor driver. It is not only power-saving, but also can realize the stepless speed adjustment, especially when coordinate with the extra large flywheel, which make the die-cutting force strong and steady, and the electricity can be further reduced.

4. The coordination between stepping motor and photoelectric eye which can identify colors assures the perfectly fit of the die-cutting position and figures.

>>> RFQ

1.Q:What is the machine warranty?

A:one year.

2.Q:Does your machine with CE certificate?

A:Yes.

3.Q:What is the production time while placing order?

A:About 30 days

4.Q:What is the delivery time?

A:Within 30 days after get the payment.

5.Q:Can your company handle shipping for customers?

A:Yes.(Please provide us your requested seaport and we can check the shipping charge and arrange shipping for your order)

6.Q:Does the packing strong?

A:Yes, of course! All of our export packing is with strong wooden pallets, all are confirmed to export packing standard.

7.Q:How about after-sales service process?

A:When your machine has problem, contact your sales and we will solve your problem soon as possible.

8.Q:Are you manufacturer?

A:Yes, we are manufacturer with 10-year experience and profession.

9.Q:Do you have stock product to sell?

A:Actually our machine need 20-30 days to manufacture, and there are many orders from China and foreign countries, and your order will be highly attention to manufacture.

10.Q:Do you inspect the finished products?

A:Yes, we have QC department, they will inspect the machine before shipping, to ensure there is nothing problem of the machine .

11.Q:What's the payment term?

A:T/T 30% in advance, the balance paid before delivery. We also accept payment via West Union and L/C.

We are professional manufacturer since 2010. We believe our products will provide you with great business benefits and advantage.

Contact Person: Marco Lin

Zhejiang Feida Machinery Co.,Ltd

NO.529, Zhengsong Road, Wanquan Town, Pingyang City, Zhejiang, China

Video: feidamachine.en.made-in-china.com