Automatic Lead Edge Rotary Die Cutter Machine for Clrrugated Carton Box Making

DONGGUANG XINGLONG PACKAGING MACHINERY CO., LTD.- Species:Rotary Die-Cutting Machine

- Imprinting Type:Rotary Platen

- Placing Form of Template:Vertical

- Die Cutting Tool:Steel Blade

- Computerized:Computerized

- Automatic Grade:Automatic

Base Info

- Model NO.:AM-1020

- Application:Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials, Earthquake Products

- Model:Am-1020

- Voltage:380V

- Certification:Ce, ISO9001:2008

- Warranty:1 Year

- Max Cardboard Size:2000*1000mm

- Min Cardboard Size:350*630mm

- Weight:2000kg

- Motor Power:5.5kw

- Adoptable Thickness of Paperboard:2-10mm

- Max Speed:140PCS,Min

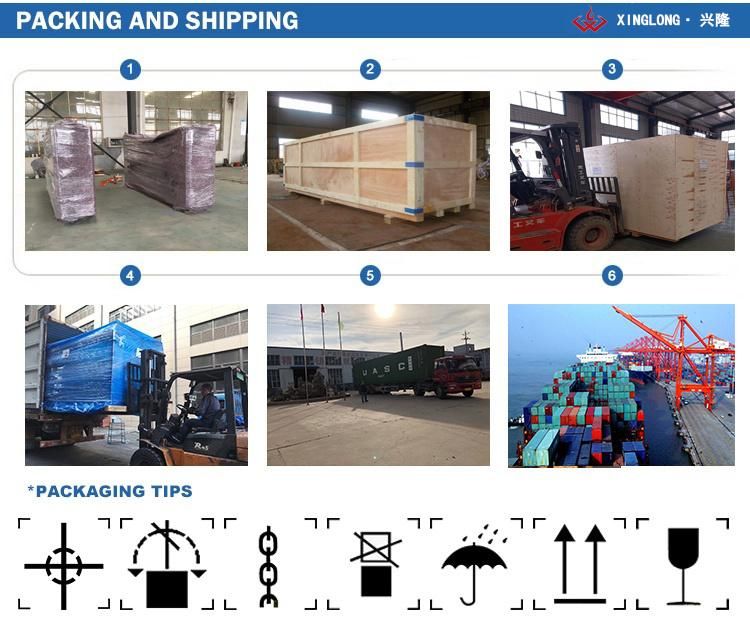

- Transport Package:Wodden Case, Container

- Specification:other

- Trademark:XINGLONG

- Origin:Hebei, China

- HS Code:4401210010

- Production Capacity:2set,Month

Description

Basic Info.

Model NO. AM-1020 Application Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials, Earthquake Products Model Am-1020 Voltage 380V Certification Ce, ISO9001:2008 Warranty 1 Year Max Cardboard Size 2000*1000mm Min Cardboard Size 350*630mm Weight 2000kg Motor Power 5.5kw Adoptable Thickness of Paperboard 2-10mm Max Speed 140PCS/Min Transport Package Wodden Case, Container Specification other Trademark XINGLONG Origin Hebei, China HS Code 4401210010 Production Capacity 2set/MonthProduct Description

Automatic lead edge rotary die cutter machine

Function and uses:

The machine adopts automatic lead edge feeding system and double roller rotary type. It can perform all process of slitting, creasing, corner cutting and hit special hole at one time. It has advantage of high precision, easy to operate, high speed ,long service life and low cost.

Technical parameter:

| Model | AM-918 | AM-1020 | AM-1222 | AM-1424 |

| Max. Cardboard size | 1800×900mm | 2000*1000mm | 2200*1200mm | 2400*1400mm |

| Min. Cardboard size | 350×630mm | 350*630 | 350*630 | 350*700mm |

| Total power | 5.5kw | 5.5kw | 7.5kw | 7.5kw |

| Max. speed | 140pcs/min | 130pcs/min | 120pcs/min | 100pcs/min |

| Adoptable thickness of paperboard | 2-10mm | 2-10mm | 2-10mm | 2-10mm |

Main characteristics:

▓Automatic compensation device for linear speed of rubber cushion roller to prolong the service life of superior adhesive.

▓The lead edge feeding has the advantages of good stability, fast working speed, low failure rate and high efficiency.

▓The rubber feeding roller with resorte device, feeding accurately, stably, not destroy paperboard strength if the feeding space is very small.

▓The left and right side baffles adopt electric control , the back baffles adopt electric adjustment, the front baffle space manual sync adjustment.

▓Equipped with colors touch screen take 360 degree set to die roller, display product speed and set production quantity.

▓Automatic lateral movement of cushion roller 40 mm from left to right, prolonging the service life of superior rubber

▓When the rubber pad is used unevenness, can open the function of the rubber roller, prolong the service life of the rubber pad.

▓Adopt high-quality Germany Depair rubber pad.

▓The roller is made of cast steel, with a wall thickness of 45mm,

▓Pneumatic manual or automatic control of die cutting roll, die cutting roll to lift cutting paper, stop the paper feed to fall to avoid damage to the rubber pad.

▓Electrically adjusted phase die-cutting position

▓The transmission gear is automatically sprayed and lubricated, and the service life of the gear is prolonged.

FAQ:

1. Q: What is your delivery term?

A: FOB,CIF,CFR usually.

2.Q: What is your payment?

A: T/T.30% deposit, 70% balance before delivery.

L/C. 100% at sight.

T/T and L/C, 30% TT deposit, 70% L/C.

3.Q: What is your delivery time?

A: Die cutting machine, 30-40 days usually. If urgent, 15 days only.

Paper cutting machine, 20-30 days usually. If urgent, 15 days only.

4.Q: What is your warranty and other terms?

A: One year warranty. Spare parts are free for customer in 1 year, but customer have to pay delivery. We can send our engineer to customer factory for 7 days free installing and trainning, customer have to pay tickets, visa, meals and hotel. If need more training, $100.00 per day to our engineer.