Full Hydraulic Paper Cutter/ Paper Cutting Machine/Guillotine 68e

Zhejiang Guowei Intelligent Equipment Co., Ltd.- After-sales Service:Lifelong Service

- Warranty:1 Year

- Classification:Single-blade Cutter

- Driven Type:Hydraulic

- Type:Industrial Cutter

- Blade Material:Stainless Steel

Base Info

- Model NO.:68E

- Computerized:Computerized

- Resolution Rate:0.01mm

- Max Paper-Pushing Speed:5-10m,Min

- Max Cutting Width:68cm

- Height of Working Table:92cm

- Cutting Speed:20r,Min

- Power of Main Motor:1.5kw

- Max Paper Pressure:10000n

- Machine Weight:800kg

- Max. Cutting Depth:68cm

- Total Length of Working Table:145cm

- Transport Package:Wooden Case

- Specification:CE

- Trademark:GUOWEI

- Origin:China

- HS Code:84411000

- Production Capacity:1000 Sets,Year

Description

Basic Info.

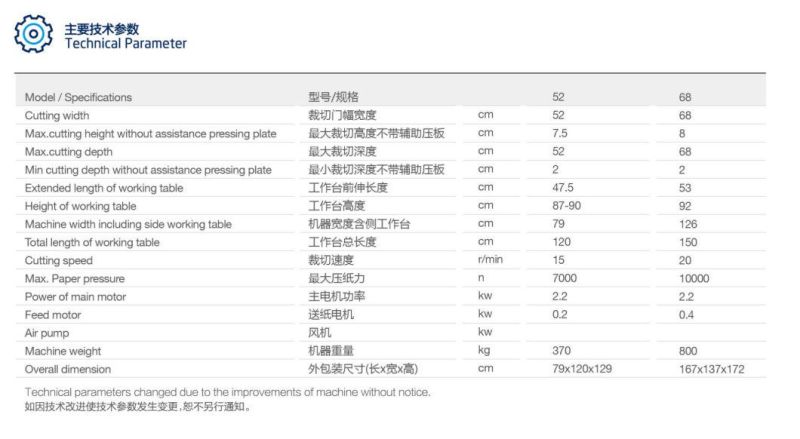

Model NO. 68E Computerized Computerized Resolution Rate 0.01mm Max Paper-Pushing Speed 5-10m/Min Max Cutting Width 68cm Height of Working Table 92cm Cutting Speed 20r/Min Power of Main Motor 1.5kw Max Paper Pressure 10000n Machine Weight 800kg Max. Cutting Depth 68cm Total Length of Working Table 145cm Transport Package Wooden Case Specification CE Trademark GUOWEI Origin China HS Code 84411000 Production Capacity 1000 Sets/YearProduct Description

Full Hydraulic Paper Cutter/ Paper Cutting Machine/Guillotine 68E1.The picture of our machine

2. Introduction

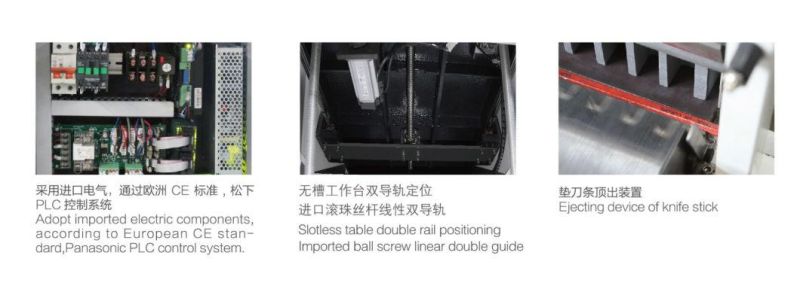

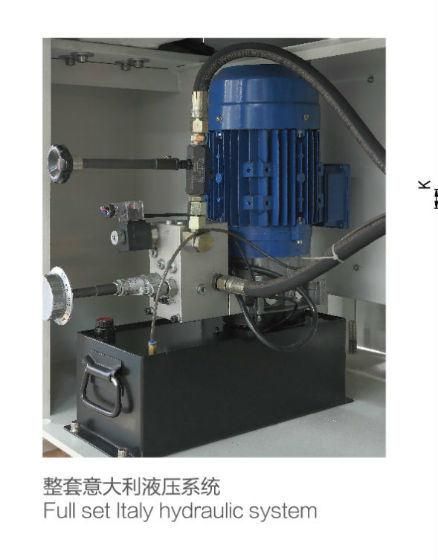

Cutting knife and paperweight are controlled by hydraulic transmission. Fully hydraulic drive makes the machine more secure and imported hydraulic parts ensure the stability of the system. The machine has the function of a reference setting and keeping, and the effectiveness of the reference and self-diagnostic function; infrared protection and hands button interlock protection device; pusher guide linear double guide, high precision of alignment and rear angle. Computer system adopts 10-inch colorful full-touch screen, servo motor driven,. The data resolution is 0.01mm, with self-diagnostic function and operation mode display, 100 program groups, more than 10,000 different cutting positions, dynamic tracking, max paper pushing speed 5-10 m / min, and it has imported hydraulic components,electrical configuration for the programmable logic controller PLC, electric components from France, Japan, Korea. Its key parts adopt imported bearing of low maintenance.

3.Main Specification

4.The System Of Computer:

1.The displaying panel use 10 inch, you can adjust the color by yourself.

2.They have the high quality colors(25600), their storage can reach 100 groups,every group have 100 cut, Its storage time can reach 300,000 hours.

3.There are 8 multi-language operating interface, such as Chinese,English,Spanish...

4.It has colorful touching screen so as to ensure the high stability.

5.The Apparatus Controlled Ssystem:

| No. | Name | Brand Model | Origin |

| 1 | Display screen | 10 10inch Color touch screen | Taiwan |

| 2 | Ball lead screw | ABBA Ball screw | Taiwan |

| 3 | Control center | PLC/Panasonic PLC | Japan |

| 4 | Linear guide | High-precision linear double guide | Taiwan |

| 5 | Servo motor | Panasonic servo drive | Japan |

| 6 | Servo drive | Panasonic servo drive | Japan |

| 7 | Bearing | NSK | Japan |

| 8 | Locating switch | OMRON | Japan |

| 9 | Power switch | MEAN WELL | Taiwan |

| 10 | Relays | IDEC | Japan |

| 11 | Contactor | Sch | France |

| 12 | Hydraulic system | Brevini | Italy |

| 13 | Knife | BAIDI | Shanghai |

| 14 | Hydraulic Pump | Brevini | Italy |

| 15 | Body | HT2500 | Wanjin |

| 16 | Bed knife | HT3500 | Wanjin |

| 17 | Blade | Made in UK | England |

| 18 | IR | SWD | China |

| 19 | Main Motor | OTK | Italy-China |

6. The advantage of our company

(1) Over 25 years of international leading cutting equipment manufacturer

(2) Applied range including Paper sheet,Plastic sheet,Foil,Honeycomb board,Cardboard,Carbon fiber laminate,Leather,Glassine and Packing sheet ect.

(3)We have a special business mode,which is personalized production.We provide customized service according to each customer's specific way of production with the features of productions.

(4)We have our own warehouse to ensure the supply of spare parts at any time.

(5)Strictly follow ISO quality control, competitive price, fast delivery.

7.The Safety Production System:

1.Imported ball lead screw.

2. IR photoelectric protection and hands operating protection

3. Ejecting device for cutting stick

4. Inside electronic knife locker

5. Safety and convenience knife replacement system

6. Overloading protection device for cutting

7.Flat worm speed reducer transmission.

8.PLC control system

8.The Accessory With Machine:

1. Tool box: 1 set

2. Manual book

3. Guarantee sheet(details in contract

9.The Payment Terms:

30% TT in advance, balance before shipment.

10.The Delievry Time:

About 25 days after receipt of the deposit.