Lead Edge Feeder Flat Bed Creasing and Die Cutting Machine/High Speed Die Cutting Machine/Flat Bed Die Cutting and Creasing Machine

HRB PACK GROUP CO., LTD.- Species:Die Cutting and Creasing Machine

- Imprinting Type:Platen

- Placing Form of Template:Horizontal

- Die Cutting Tool:Steel Plate

- Computerized:Computerized

- Automatic Grade:Automatic

Base Info

- Model NO.:MY1300

- Application:Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials, Earthquake Products

- Max Paper Transmitting Size:1320*980mm

- Min Paper Transmitting Size:350*450mm

- Max Die Cutting Size:1300*960mm

- Speed:5000 Sheets,H

- Die Cutting Type:Pressed Flat Die Cutting

- Total Power:24.5kw

- Dimension:5900*2365*2346mm

- Transport Package:Plastic

- Specification:MY 1300

- Trademark:HRB PACK

- Origin:China

- HS Code:8501101000

- Production Capacity:100pieces Per Year

Description

Overall size5900*2365*2346mm

System introduction

Feeding and Collecting Part

Feeding table

Diecutting part and Delivery system

Electric system

System introduction

Feeding and Collecting Part

- The extra feeder can do paper and corrugated board,Install the vacuum pump of BECKER.

- At the middle of head install the monitor ,worker can easily see the back

- Pre-paper pile design and special pneumatic bench can save much time

- The non-stop sampling system can check the board accurate without stop the machine

Feeding table

- Additional brush wheels and pressing wheels for thin paper and corrugated board running

- Advance push and pull lay of registration can assure the die cutting precision

- Rikko light front lay detection system prevent the slanting paper move in main body

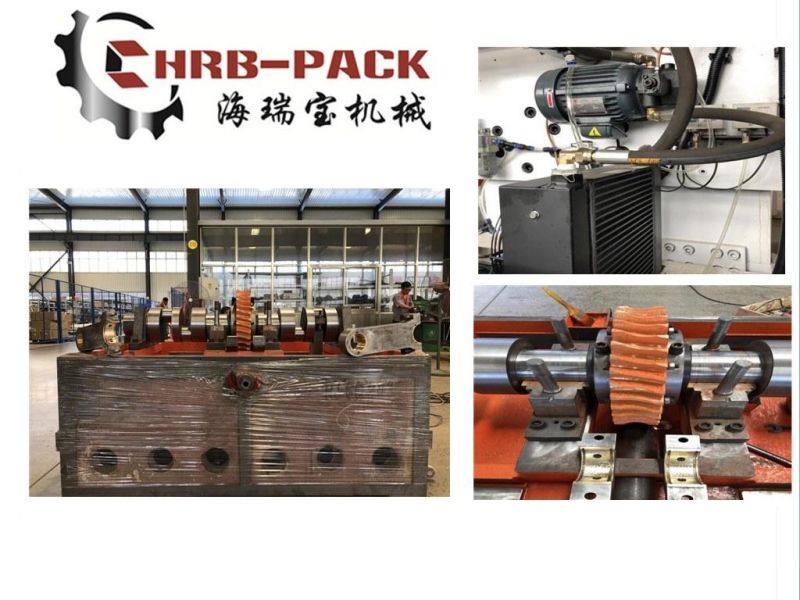

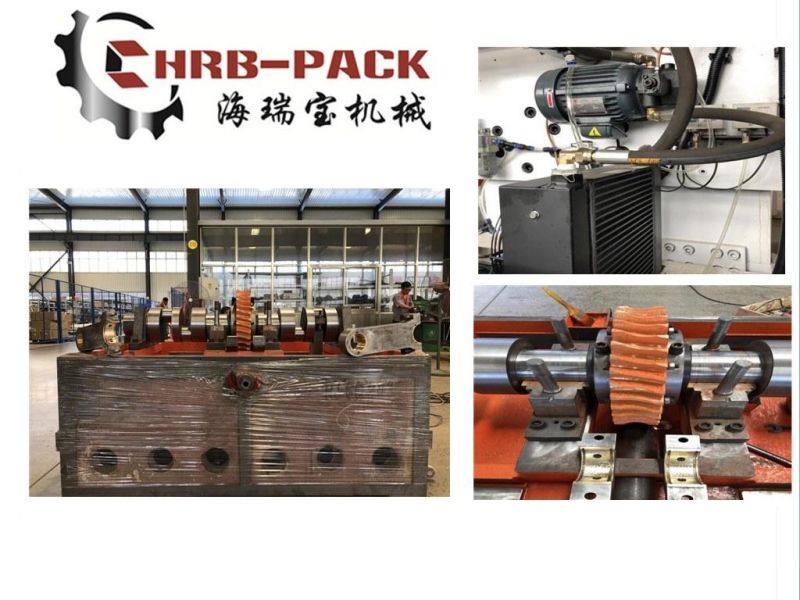

Main body

Main body - Adopt automatic centralized lubricating system and setting main chain lubricating system by HMI

- Patented design shock absorption system can prolong the life of main body and increase the pressure

- The intermittent gearbox made in Taiwan can assure the accurate registration and decrease the gripper attack

Diecutting part and Delivery system

- Diecutting chase fixed accurately by pneumatic lock system

- Diecutting plate is putted in and out by air floating device

- Electric clutch system of main chain can assure the chain steady when it is stopped at high speed

- Main chain and assist chain is lubricated periodically controlled by PLC

- Protection window of diecutting can hold the main body clean

- Lightweight and durable aluminum alloy gripper bars with chain of Renold UK or IWIS Germany ensure accurate

Electric system

- Electrical with European and Japanese famous brand imported parts in order to improve the operation quality control

- Adopt Mitsubishi PLC programmable control system ,simple circuit control procedures