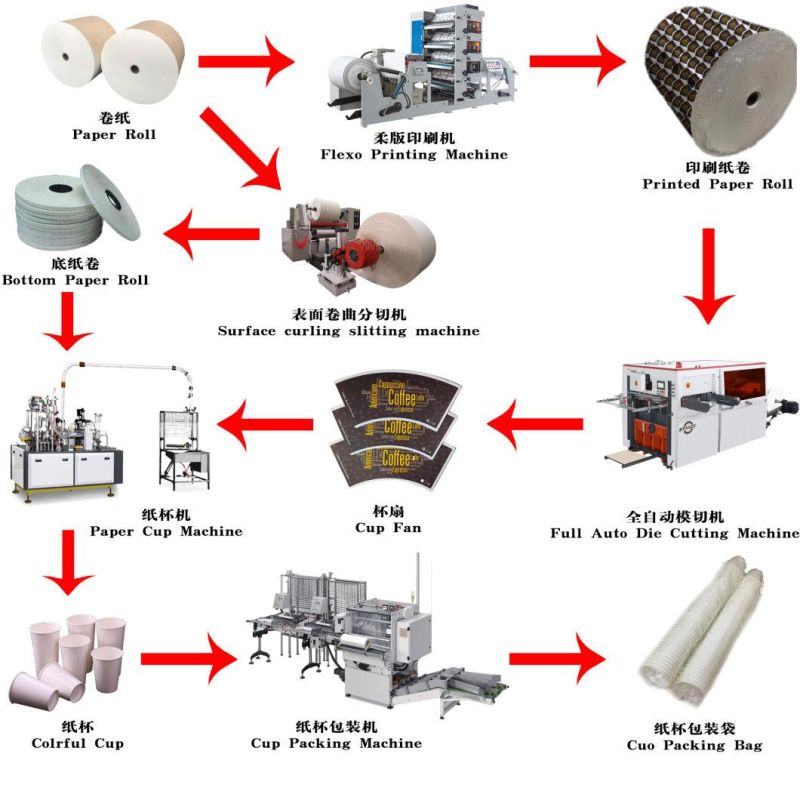

Automatic Hydraulic Loading and Unloading Roll Die Cutting and Creasing Heavy Duty Machine

Ruian Nice Machinery Co., Ltd.- After-sales Service:1 Year

- Warranty:1 Year

- Species:Rotary Die-Cutting Machine

- Imprinting Type:Rotary Platen

- Placing Form of Template:Horizontal

- Die Cutting Tool:Metal Mold

Base Info

- Model NO.:NICE-970*640

- Computerized:Computerized

- Automatic Grade:Automatic

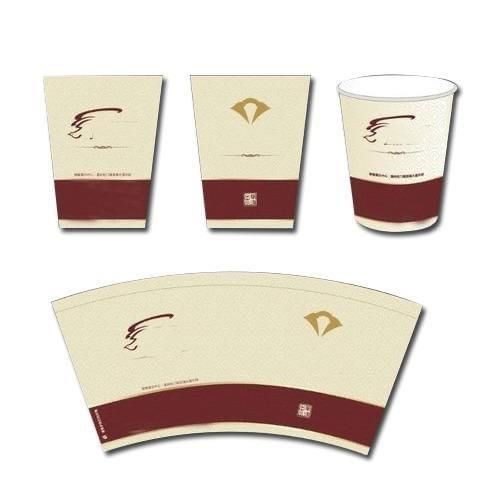

- Application:Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials, Earthquake Products

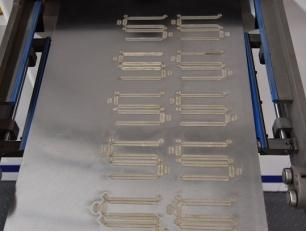

- Cutting Precision:±0.15mm

- Transport Package:Wooden Packaging

- Specification:4500x2200x1800

- Trademark:NICE

- Origin:China

- HS Code:8441100000

- Production Capacity:20sets,Month

Description

Motor:

Motor:Frequency converter controls the main motor, with features of low energy and high efficiency.

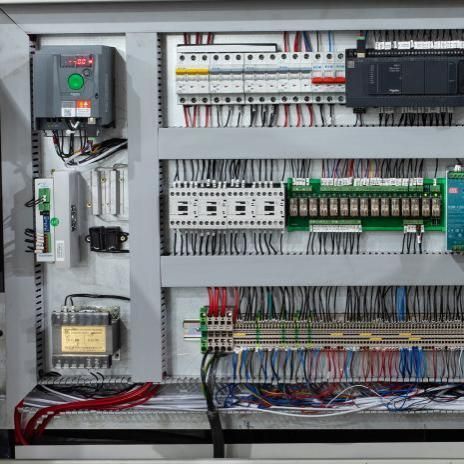

Electrical control system:

adopts micro computer control, encoder angle detect and control, photoelectric chase and detect, achieving from paper feeding, convey, die-cutting and delivering process automatic control and detect.Pneumatic clutch brake:

through adjust the air pressure to control the driving torque, low noise and high brake performance. The machine will shut down automatically if overload happened, response sensitive and fast.

The die-cutting force is provided by a 7.5KW inverter motor driver. It is not only power-saving, but also can realize the stepless speed adjustment, especially when coordinate with the extra large flywheel, which make the die-cutting force strong and steady, and the electricity can be further reduced.

Die cutting plate:

Die cutting plate: 65Mn steel plate heating treatment, high hardness and flatness.

Die cutting knife plate and plate frame can be take out so that it can save plate-changing time.

Die cutting department adopts pneumatic lock version of the device to avoid come off from the machine.

Worm Gear Structure:

Perfect worm wheel and worm transmission system ensures the powerful and steady pressure and makes the cutting accurately while the machine runs with high speed, has features of low noise, smooth running and high cutting pressure Main base frame, moving frame and top frame are all adopts high strength Ductile Cast Iron QT500-7, which has features of high tensile strength, anti-deformation and anti-fatigable.

Automatically fold:

Automatically fold:Automatically fold and flatten the cornering materials at the paper core. It realized the multistage adjustment of the folding degree. No matter how bent the product is, it can be flatten or refolded towards other directions.

>>> RFQ

1.Q:What is the machine warranty?

A:one year.

2.Q:Does your machine with CE certificate?

A:Yes.

3.Q:What is the production time while placing order?

A:About 30 days

4.Q:What is the delivery time?

A:Within 30 days after get the payment.

5.Q:Can your company handle shipping for customers?

A:Yes.(Please provide us your requested seaport and we can check the shipping charge and arrange shipping for your order)

6.Q:Does the packing strong?

A:Yes, of course! All of our export packing is with strong wooden pallets, all are confirmed to export packing standard.

7.Q:How about after-sales service process?

A:When your machine has problem, contact your sales and we will solve your problem soon as possible.

8.Q:Are you manufacturer?

A:Yes, we are manufacturer with 10-year experience and profession.

9.Q:Do you have stock product to sell?

A:Actually our machine need15-30 days to manufacture, and there are many orders from China and foreign countries, and your order will be highly attention to manufacture.

10.Q:Do you inspect the finished products?

A:Yes, we have QC department, they will inspect the machine before shipping, to ensure there is nothing problem of the machine .

11.Q:What's the payment term?

A:T/T 30% in advance, the balance paid before delivery. We also accept payment via West Union and L/C.

We are professional manufacturer since 2009. We believe our products will provide you with great business benefits and advantage.