Automatic Blanking Machine

Zhejiang Huawei Machinery Co., Ltd.- Blanking Head Type:Twin Head

- Customization:Supported

- Transport Package:Null , Wooden Box

- Specification:3500 x 1800 x 1900mm

- Trademark:Huawei

- Origin:Wenzhou

Base Info

- Model NO.:MS-1080

- Production Capacity:100+ Sets , Year

Description

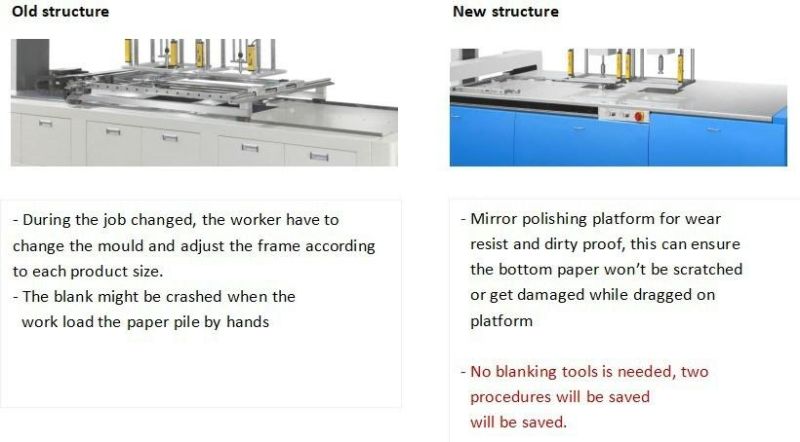

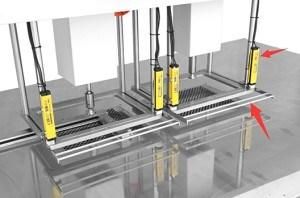

Double safe protection

the oil cylinder can goes down slowing when you

press the inching bottom, more convenient for

job change over.

Protection 1 : Mechanical safe protection

Protection 2: High density safe light curtain

After the blanking material has been picked up, the

sheets automatically slide into place, and blanking

is performed efficiently.

By simply arranging the pins, the blanking machine

can blank a variety of product shapes and sizes.

| Precise arranging pins loader | Mature manufacturing technique |

- The high density stripping pin loader is made by CNC processing center. - Reasonable and compact design makes the stripping pin changing jobs are easy and fast. - High precision and no need to change blanking tools  | The whole machine parts and accessories are made by fully automatic CNC processing center. Sealed and compact structure, dust proof. Longer machine service life. |

Solid structure and bear high pressure | Double servo, Ball-Screw and LM Rail Drive Systems |

The new generation of blanking machine adopts a double cross beam structure. This structure is much more solid and it won't get crushed due to high pressure (especially for big models)  | The ball screw is driven by double servo to ensure the high product precision By using the Ball-Screw and LM Rail Drive Systems, blanking precision with smooth and quiet operation is realized. |