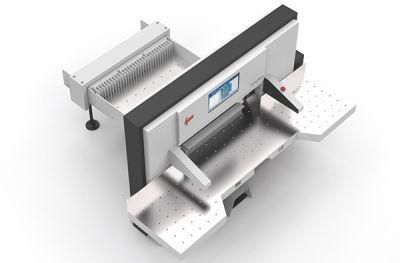

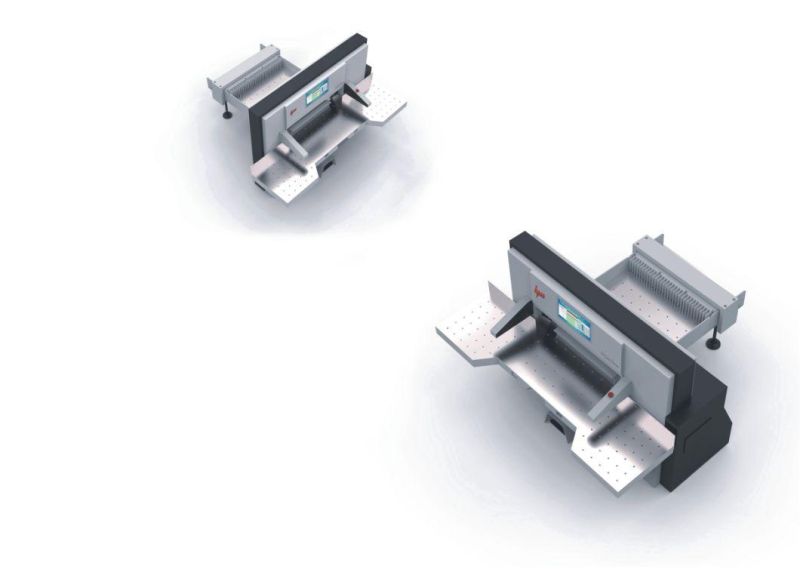

Automatic High Speed Intelligent Guillotine Program Control Hydraulic Heavy Paper Cutting Machine P

Zhejiang Huayue Packing Machinery Co., Ltd.- Classification:Single-blade Cutter

- Driven Type:Hydraulic

- Type:Industrial Cutter

- Blade Material:HSS

- Computerized:Computerized

- Full Touch Screen:15.6inch

Base Info

- Model NO.:SQZK78,92,115,130,137(G)

- Size:137cm

- Colour:Gray

- Max. Backgauge Speed( M/Min):38m,Min

- Language:Eight Languages Can Choose

- Transport Package:Fumigated Wooden Case

- Specification:92,115,130,137,168,188cm

- Trademark:HPM

- Origin:China

- HS Code:84411000

- Production Capacity:1000 Unit,Year

Description

Basic Info.

Model NO. SQZK78/92/115/130/137(G) Size 137cm Colour Gray Max. Backgauge Speed( M/Min) 38m/Min Language Eight Languages Can Choose Transport Package Fumigated Wooden Case Specification 92/115/130/137/168/188cm Trademark HPM Origin China HS Code 84411000 Production Capacity 1000 Unit/YearProduct Description

HPM M15 Program Control Paper Cutter

Computer System

1. The up-to-date 15.6" Widescreen LCD, full touch screen; Siemens PLC control.

2. Eight languages to choose.

3. Metric system and British system two units, show the dimensions of the front knife and the back knife.

4. Step less speed adjustment function with latest technology , to make the cutting speed from 30 to 48 times within 1 minute , no need to change knife angle for different cutting material.

5. Position resolution of backgauge is 0.01mm, closed-loop control, the locating error is less 0.01mm; No need to adjust locating error. Max. backgauge speed is 30-38m/min. 20-30 m/min . 15-20 m/min. 12-15 m/min .(four class to adjust).

6. The program storage capacity is 300 programs. Every program can store 299 items cutting sizes. The storage memory has a maximum of 40 years.

7. With USB, transmit data, to convenient operator make programming and arrangement via PC.

8. Equipped with fault diagnostics and non-repeat safety guards.it can detect all the position switch state and dynamic prompt switch failure.make the machine more convenient maintenance.

9. The backgauge is driven by a Panasonic servo-motor with four speed levels.

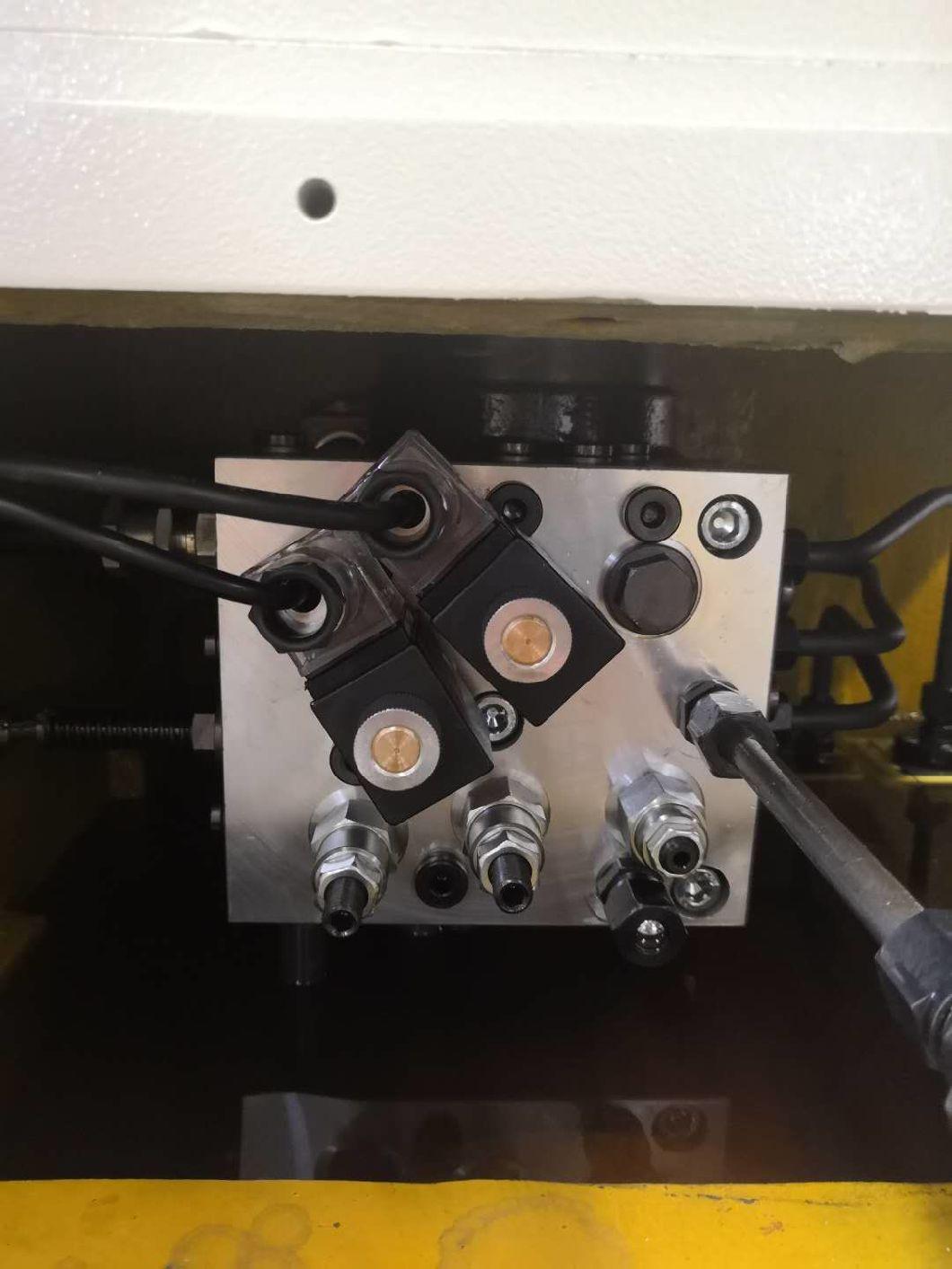

10. Use Italy oil pump and hydraulic system.

11. With automatic pushing paper function, the distance can be adjusted.

12. Adjustable time delay for knife activation, accurate and convenient.

13. Uses icons to show operational functions, which are simple and user friendly.

14. With full automatic cutting function. The backgauge and knife movements can be monitored on the screen.

Machine Performance

1. Knife-seat guiding structure with sliding block type, cam type for adjusting-knife mechanism.

2. Clamp press paper stack through hydraulic system, the spring re-position.

3. Worm gear drive mechanism, hydraulic clutch, mechanical brake.

4. Hydraulic system adopts Germany advanced technology, the hydraulic units are ISO approved, Italy oil pump.

5. One-piece, slot less and chrome-plated cast iron work table is sturdy and easy to maintain.

6.Import ball screw with double linear guides to drive backgauge.

7.High safety infrared protection device according to CE standard.

8.Main electronic units are from French TE and Japanese ORMON famous international brands.

Configuration Listing

| No | Name | Brand, specification & model | Origin of brand |

| 1. | Background LCD | 15.6''Color touch Interface | Taiwan |

| 2. | Control center | Siemens PLC (CPU224) | Germany |

| 3. | Backgauge position motor | PANASONIC servo motor | Japan |

| 4. | Pick-up | Autonics | Korea |

| 5. | Limit switch | TE | France |

| 6. | Guarding motor | TE | France |

| 7. | Air switch | TE | France |

| 8. | AC Contactor | TE | France |

| 9. | Miniature relay | OMRON | Japan |

| 10. | Switching power supply | TE | France |

| 11. | Power switch | Moeller | Germany |

| 12. | Ball screw | High accurate | Taiwan |

| 13. | Linear guider | High accurate double linear guides | Taiwan |

| 14. | Hydraulic system | Double gear pump | Italy |

| 15. | Bearing | NSK | Japan |

| 16. | Work Table | Slotless and plated chromium work table | China |

| 17 | HSS knife | Kanefusa | Japan |

Technical Parameter

| Model | Unit | 92 | 115 | 130 | 137 | 168 |

| Max.Cutting Width | cm | 92 | 115 | 130 | 137 | 168 |

| inch | 36.2 | 45.3 | 51.2 | 53.9 | 66.1 | |

| Max.Cutting Length | cm | 92 | 115 | 130 | 145 | 168 |

| inch | 36.2 | 45.3 | 51.2 | 57.1 | 66.1 | |

| Max. Cutting Height | mm | 120 | 165 | 165 | 165 | 165 |

| inch | 4.7 | 6.5 | 6.5 | 6.5 | 6.5 | |

| Min. Cutting Size (without false clam pplate) | mm | 25 | 30 | 30 | 30 | 30 |

| inch | 1 | 1.2 | 1.2 | 1.2 | 1.2 | |

| Min. Cutting Size (with false clamp plate) | mm | 90 | 90 | 90 | 90 | 90 |

| inch | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | |

| Front Table Length | cm | 63.2 | 71.5 | 73 | 73 | 75 |

| inch | 24.9 | 28.1 | 28.7 | 28.7 | 29.5 | |

| Max.Clamp Pressure | N | 30000 | 40000 | 40000 | 45000 | 60000 |

| Max. Cutting Speed | time/min | 42 | 43 | 43 | 43 | 43 |

| Main Motor | KW | 3 | 4 | 4 | 4 | 8.5 |

| Net Weight | Kg | 2300 | 3700 | 3900 | 4100 | 6200 |

| Gross Weight | Kg | 2500 | 4100 | 4300 | 4500 | 7000 |

| Packing Size(L×W×H) | cm | 228×140×188 | 285×190×210 | 285×190×210 | 310×190×210 | 360×205×220 |