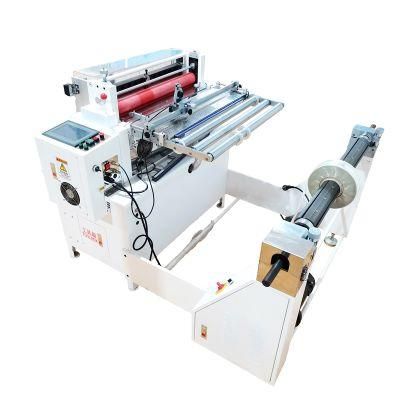

Automatic Non Woven Fabric Roll to Sheet Cutting Machine

Kunshan Hexin Precise Machinery Co., Ltd.- After-sales Service:Online

- Warranty:1year

- Classification:Double-blade Cutter

- Driven Type:Mechanical

- Type:Industrial Cutter

- Blade Material:Stainless Steel

Base Info

- Model NO.:HX-600B

- Computerized:Computerized

- Voltage:380V

- Power:1470W

- N.G:320kg

- Cutting Length:0.1-9999.9mm

- Cutting Width:1-600mm

- Cutting Precision:0.05mm

- Cutting Speed:125cut ,Min

- Measurement:1500*1300*1200mm

- Transport Package:Plywood Case

- Specification:CE ISO

- Trademark:Hexin

- Origin:Kunshan City, Jiangsu Province, China

- HS Code:845150000

- Production Capacity:100 Sets Per Month

Description

Basic Info.

Model NO. HX-600B Computerized Computerized Voltage 380V Power 1470W N.G 320kg Cutting Length 0.1-9999.9mm Cutting Width 1-600mm Cutting Precision 0.05mm Cutting Speed 125cut /Min Measurement 1500*1300*1200mm Transport Package Plywood Case Specification CE ISO Trademark Hexin Origin Kunshan City, Jiangsu Province, China HS Code 845150000 Production Capacity 100 Sets Per MonthProduct Description

Automatic non woven fabric roll to sheet cutting machine

Product Description

1.This machine emplys servo motor to feed material, count NO. automatically and accurately.

2.PLC control system is Mitsubishi, can set any length,quantity,speed, etc.

3.Equipped with automatic unwinding system and air shaft, which will be easy to load and unload.

4.Cutting speed is 125cut/min

5.Roll to sheet( sheet precision is ± 0.05mm. )

6.Cutting width is 1-600mm.

Technical Parameters

Model | HX-600B |

Cutting Length | 0.1~9999.9mm |

Cutting Width | 1~600mm |

Power | 1500W |

Voltage | 380V |

N.W. | 320kg |

Measurement | 1500x1300x1200mm |

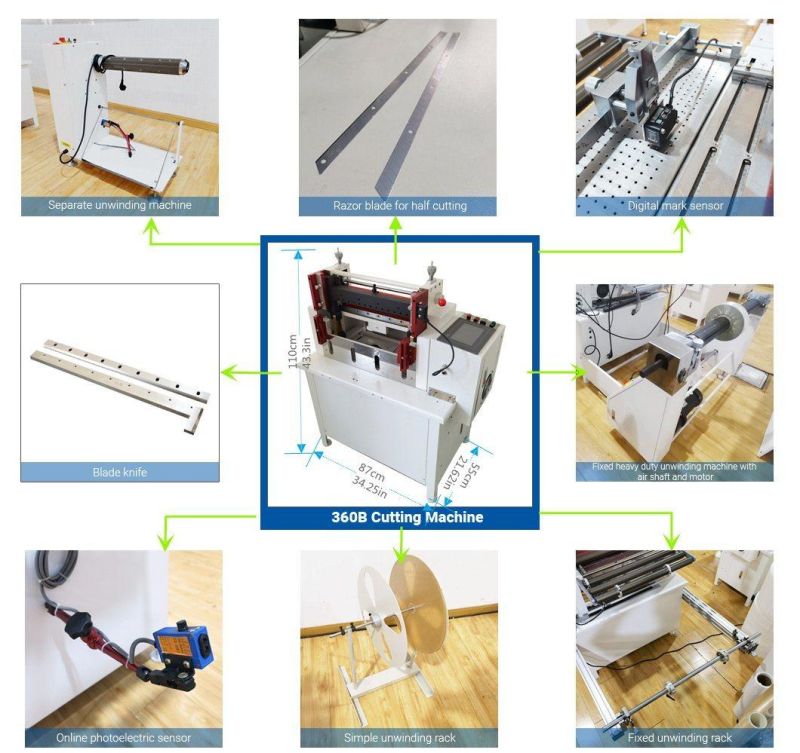

Machine Features

1. Max material width: 600mm;

2. Tolerence: 0.05mm, Precision:±0.05mm;

3. Material thickness range: 0.5mm-15mm;

4. Cutting speed:125 cut/min;

5. Both kiss-cut and complete cut are available;

6. Complete cut is for standard machine, and kiss-cut is an option;

7. A conbination of PLC and servo motor.

8. An air shaft as the loading shaft;

9. Two accessories, static eliminator and conveyor belt, for you choose

10. Automatic unwinding function;

11. Cutting length is accurate;

12. Operation is easy;

13. Waste rate is low;

14. Diverse functions satisfy your various requirements;

15. We offer superior-quality products and best service for you;

16. As a high-tech manufacturer, we possess veteran engineers and professional sales team;

17. Manufacturing experience: 10 years;

18. Export experience: 5 years.

Application

Size cutting for flannelette, metal foil, PET, PC, PVC, PCB, FPC, lithium battery film, and all kinds of material in roll form.

Our Service

1. A warranty period of 12 months

2. A prompt reply within 24 hours

3. Free operation training before delivering.

Samples Show

FAQ

1. Q: Are you a manufacturer or trading company?

A:We are a manufacturer.

2. Q: Where is your factory located in? How can I visit there?

A:Our factory is located in Building 9, No. 157, Wulian Road, Yushan Town, Kunshan, Suzhou City, Jiangsu Province, China (Mainland). You can fly to Shanghai airport directly. We warmly welcome all our clients from home and abroad to visit us!

3. Q: What are your main products ?

A: Our main products are slitting machines, sheeting machines, laminating machines and Die cutting machines.

4. Q: Which industries are your machines widely used in ?

A: All industries need to cut (include full cutting and kiss-cutting), slice, laminate, rotary die cut raw materials can use our machines.

5. Q: How does your factory do regarding quality control?

A: Quality is priority. We control the quality of our products strictly, from the incoming materials to the finished products. Our factory has obtained CE & ISO Certification.

Believe us! Select us! Contact us!