Automatic PP or PE Film Window Patching Machine

Tangshan Jiasun Import and Export Co., Ltd.- Model:Xltc1020

- Max Paper Size(mm):1080*630

- Min Paper Size(mm):140*140

- Max. Film Size(mm):410*300

- Min.Film Size(mm):80*60

- Film Thickness(mm):0.05-0.2

Base Info

- Model NO.:XLTC 1020

- Max.Working Speed:8000s,H

- Transport Package:Pallet

- Specification:CE

- Trademark:XLTC

- Origin:China

- HS Code:8441309000

- Production Capacity:150 Sets,Year

Description

Basic Info.

Model NO. XLTC 1020 Max.Working Speed 8000s/H Transport Package Pallet Specification CE Trademark XLTC Origin China HS Code 8441309000 Production Capacity 150 Sets/YearProduct Description

1.Specification:| Model | XLTC-1020 (Single Line) |

| Max.Paper Size(mm) | 1080*630 |

| Min.Paper Size(mm) | 140*140 |

| Max. Film Size(mm) | 410*300 |

| Min.Film Size(mm) | 80*60 |

| Film Thickness(mm) | 0.05-0.20 |

| Max.Working Speed | 6000s/h |

| Cardboard | 200-500g/m2 |

| Corrugated Paper | ≤3mm |

| Total Power | 9Kw |

| Total Weight | 2650kg |

| Overall Dimensions(mm) | 5000*1960*1750 |

| (When the roller pull out) | 5000*3160*1750 |

The machine has passed the ISO9001 Quality System Certificate and conform the European CE safety standard.

3.Features by parts:

- Paper Feeding Part:

Perfect for the cardboard and corrugated.

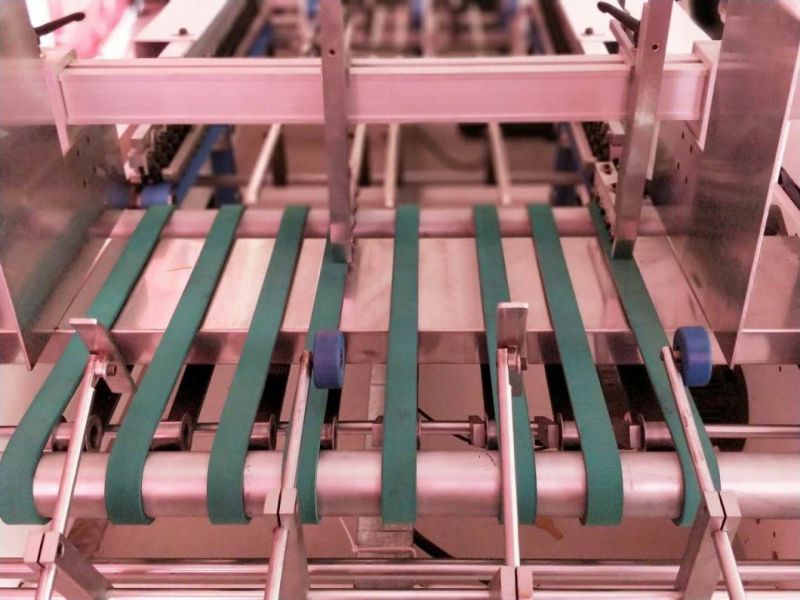

2.Conveying PartsThe paper conveying parts installed the four conveying chains with the four pushing blocks,it can be adjusted according to the paper shape.It is equipped with the 4 photosensor,detect the paper reaching condition,counting , paper jammed detection.

3.Gluing PartsThe gluing parts adopt the adjustable parts gluing structure, it is convenient for adjustable according to the paper requirement and the gluing position, save the gluing quantity, it is easy for pulling out the gluing parts ,convenient for washing. The gluing roller stopped the gluing when

stopped the machine.And the conveying parts dropped automatically, the gluing is not easy to print on the conveyor belts.

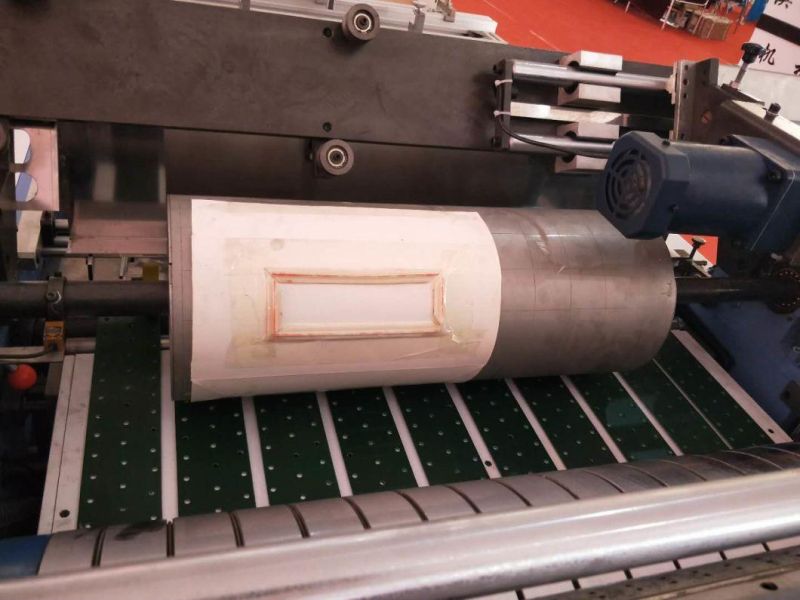

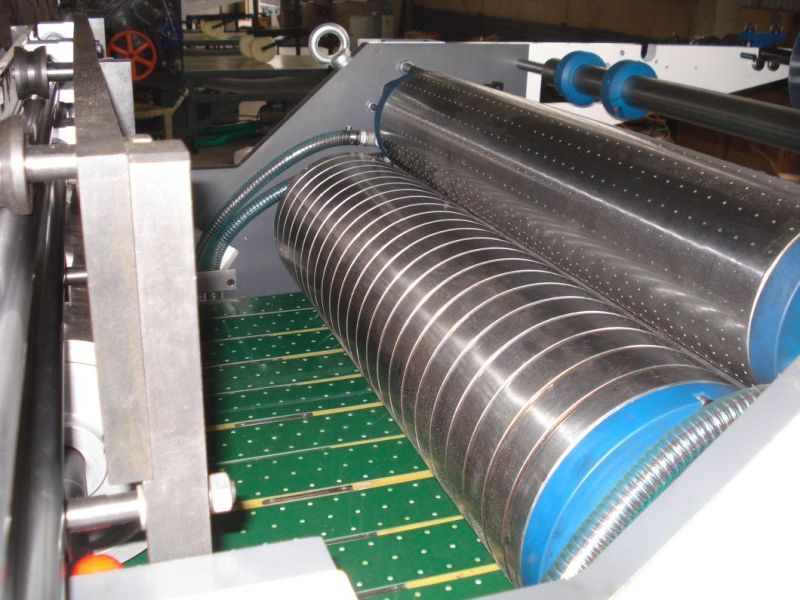

The upper roller is the cutting film roller with the two blade, one the upper blade, the other is the lower blade, finishing the cutting of the film.

The below roller is the suction roller ,the film is patched on the suction roller

Servo film adjustment :easy and convenient to adjust the film,time saving.

4.Paper Delivery partsThe patching products conveying to the paper delivery plate, finish the paper accumulation and collection

Paper delivery parts can be adjust separated.

- Electrical Components

| No. | Name | Brand |

| 1 | Intermediate Relay | OMRON |

| 2 | Breaker | SCHNEIDER(France) |

| 3 | Photoelectric Switch | OMRON(Japan) |

| 4 | Bearing(Main Parts) | SKF(Switerland) |

| 5 | Transformer | TENGEN |

| 6 | Frequency Converter | DELTA |

| 7 | Principle Logic Controller | VIGOR |

| 8 | Servo Motor/Driver | TECO |

| 9 | Vacuum Pump | TONGYOU(ZHEJIANG) |

| 10 | Three Phase Motor | JSCC AUTOMATIC (XIAMEN) LTD. |

| 11 | Rubber Roller Motor | ZHEJIANG JIAXUE(Joint Venture) |

- Spare Parts List

| No. | Name | Quantity |

| 1 | Rubber Line | 16 |

| 2 | Spring | 10 |

| 3 | Paper Feeding Belts | 8 |

| 4 | Paper Feeding Perforating Belts | 11 |

| 5 | Harmonic Gear Sets | 1 |

| 6 | Photoelectric Switch | 1 |

Note: The above spare parts and quantity in the table are free of cost, but if the buyer needs to add the quantity of any spare part please pay for them.