A4 Paper Cutting and Packing Machines Online

Hangzhou Royall Import & Export Co., Ltd.- After-sales Service:Life Time

- Warranty:1 Year

- Classification:Double-blade Cutter

- Driven Type:Electric

- Type:Industrial Cutter

- Blade Material:Stainless Steel

Base Info

- Model NO.:RYCP-A4E5

- Computerized:Computerized

- Thickness of Cutting Paper:60-550g

- Cutting Precision:The Cutting Length 1000mm:+,-0.5mm

- Max. Speed:8-12 Reams,Min

- Transport Package:Hard Export Packaging

- Specification:ce

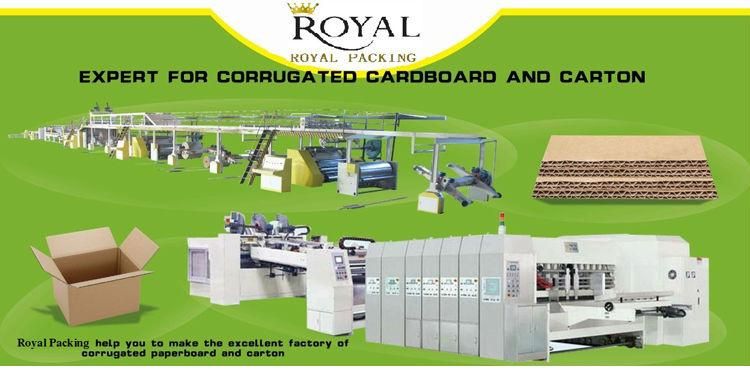

- Trademark:ROYAL PACKING

- Origin:China

- Production Capacity:1000-10000

Description

2. Paper roll with no breakage

3. Qualified paper .

(LxWx H)

(LxWx H)

Performance and Characteristics:

1. Non-shaft paper rising shelves of the ground controlling system------ Two sets

2. Advanced tension controlling system ------ Four sets.

3.Four sets of anti-warping mechanisms------Four sets.

4. Longitudinal cutting knife groups------Five sets.

5. Simultaneous cross-cutting knife groups-----One set.

6. High-speed paper feeding system----- One sets

7. Low-speed paper feeding system----- One sets

8. Waste paper automatically discharging system-----One set.

9. Making papers in order of 2D oscillation, srew rod lifting device of paper reams collecting system------One set.

10. PLC reams of paper counting device------One set.

Paper reams longitudinally and transverse discharging equipment-----One set.

PLC error alarm machine haulting system and PLC controlling equipment ------One set.

Conveying belt------One set.

Paper separator by cam rising------One set.

Paper splicer by cam rising------One set.

SPARE PARTS LIST

Earlier running, earlier Booming!