1060 X 760mm Automatic Die Cutter with Blanking

Hangzhou Ecoographix Digital Technology Co., Ltd.- Warranty:1 Year Warranty Including Spare Parts

- Species:Die Cutting and Creasing Machine

- Imprinting Type:Platen

- Placing Form of Template:Horizontal

- Die Cutting Tool:Steel Blade

- Computerized:Computerized

Base Info

- Model NO.:DS 106

- Automatic Grade:Automatic

- Application:Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials

- Max. Die-Cutting Size:1060 X 746mm

- Max Machine Speed:6500s,H

- Max. Sheet Size:1060 X 760mm

- Min. Sheet Size:400 X 350mm

- Delivery Pile Height:1200mm

- Cutting Plate Thickness:4mm

- Height of Cutting Rules:23.8mm

- Air Supply:0.8-1.0MPa, >= 0.6 M3,Min

- Transport Package:Standard Exporting Package: Polywood Carton

- Specification:7400 x 5600 x 2550mm

- Trademark:EcooGraphix

- Origin:China

- HS Code:844140

- Production Capacity:500 Sets,Year

Description

1124×788 23.8 Max. Pressure (N) 260 x 104 Stock Range Min. Gripper margin (mm) 9 Feeding pile height (mm) Air supply 0.8-1.0MPa, ≥ 0.6 m3/min 22000 ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ Automatic die cutting machine with blanking is the high end cutting machine. This model is special for the customers who want high efficiency cause this model can get the final product after cutting. Shanghai yawa is fully responsible for the quality of automatic die cutting machine with blanking, and we have rich experience and got all good feedback from our customers. ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ ---- ~~~~ Q1: What are your main products? Height of cutting rules (mm) Inter-platen distance 54 CardBoard: 157-2000g/m2 ; E, B flute Max Machine Speed (s/h) 6500 1400 Delivery pile height (mm) 1200 Rated power (kw) 28 Overall dimension (mm) 7400x5600x2550 Weight of machine (kg)

Model: DS 106

Max. Sheet Size: 1060×760mm

Min. Sheet Size: 400×350mm

Max. Die-Cutting Size: 1060×746mm

Cutting plate thickness: 4mm

Inside Chase Size: 1124×788mm

Height of cutting rules: 23.8mm

Inter-platen distance: 54

Max. Pressure: 260 x 104N

Stock Range: CardBoard: 157-2000g/m2 ; E, B flute

Min. Gripper margin: 9mm

Max Machine Speed: 6500s/h

Feeding pile height: 1400mm

Delivery pile height: 1200mm

Rated power: 28kw

Air supply: 0.8-1.0MPa, ≥ 0.6 m3/min

Overall dimension: 7400 x 5600 x 2550mm

Weight of machine: 22000kg

▪ Application

▪ Producing And Packaging

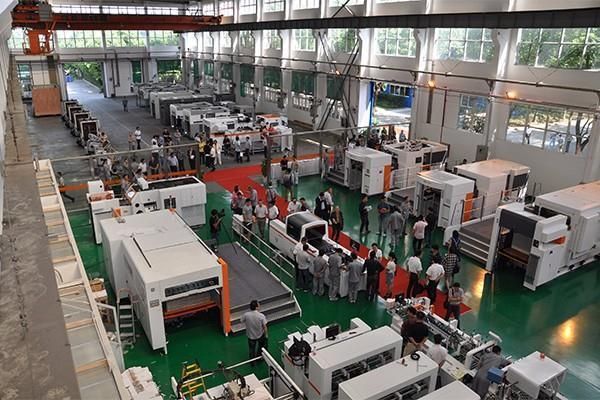

From producing to delivery, we make every details very carefully to guarantee the good product quality and service to customers.

▪ Certificates

▪ FAQ

A: Our main products are the Prepress 4up and 8up Online/Offline Thermal CTP, CTCP, VLF CTP, Flexo CTP, Processor, Offset Plates, Offset Inks, Offset printing blankets, Postpress Packing equipment and so on.

You can get the equipment and consumables all in one and no worry about the after-sales service from our company.

Q2: Where is your factory?

A: Our CTP Processor machine factory is in Shanghai, you are warmly welcomed to visit our factory!

Q3: Is there any certification for your CTP Processor?

A: Yes, all our machines have been certified by SGS and CE.

Q4: Can you also supply the Workflow and RIP?

A: Yes, we can provide the Workflow Brainnew and RIP Compose V12.

Q5: What about the installation and after-sales technician support?

A: Our engineer can go to help the installation and provide the necessary training. The buyer should take the round air plane tickets and service charge and the local accommodation cost. Any problems or questions, we will be at your disposal 7x24 hours.

Among our large amount of CTP installations worldwide, there are also many end users (printers) who have purchased the CTP products from EcooGraphix China directly and EcooGraphix technical service team support these installations remotely with regular onsite visits. These end users Printers all run the CTP systems with full satisfaction due to our robust quality, seamless remote service, thorough training and maintanence. If you are a printer who is considering purchasing directly from EcooGraphix China, there is no hasle on installations, training and after sales service. We guarantee your satisfaction.