A4 Paper Sheet Cutting and Wrapping Machine

Hangzhou Royall Import & Export Co., Ltd.- Classification:Single-blade Cutter

- Driven Type:Pneumatic

- Type:Living Paper Cutting Machine

- Blade Material:Metal

- Computerized:Computerized

- Paper Roll Width:Gross Width 860mm, Net Width 840mm

Base Info

- Model NO.:RYHM-A4

- Production Speed:8-12ream,Min.

- Paper Roll′s Diameter:Max.1500mm. Min.600mm

- Paper Core′s Diameter:3"(76.2mm)or 6"(152.4mm) or According to The Clien

- Packing Paper Grade:High-Grade Copy Paper; High-Grade Office Paper; Hi

- Paper Weight:60-100G,M2

- Sheet Length:297mm ( Specially Design for A4 Paper, The Cutting

- Ream Amount:500 Sheets Max. Height: 45-55mm

- Cutting Accuracy:About 0.2mm

- Cutting Condition:No Variation of The Speed, No Break, Cut All The P

- Transport Package:Wooden Pallet, or Steel Pallet

- Specification:CE

- Trademark:ROYAL

- Origin:China

- Production Capacity:5sets,Month

Description

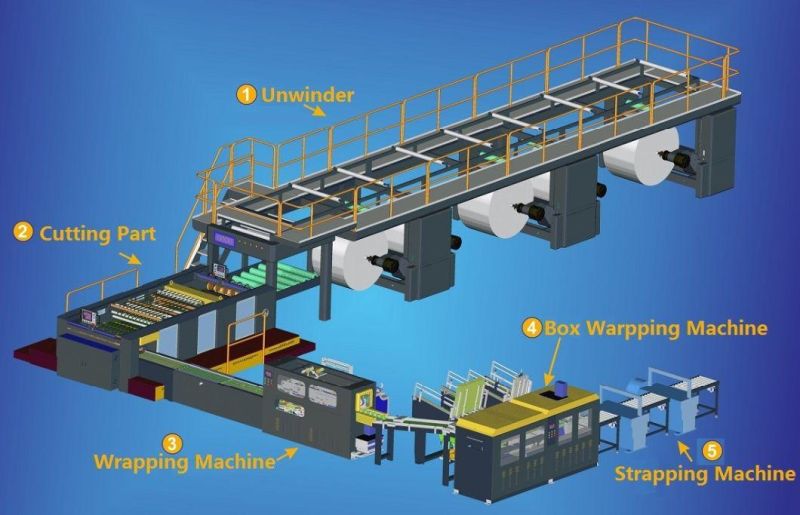

A-2 .Standard Configuration

A-2-1. Unwind Stand (1set)

A-1 Type: RYHM-1

A-2-2 High precision cutting knife system

A-2 Type: High precision cutting knife system

Upper slitting knife take by air pressure and spring. Lower knife connect with bear drive(the diameter is 180mm ) and move with spring. The upper and lower round knife is made by SKH.The lower slitting knife (diameter is 200mm) and drive with in-phase belts. The lower slitting knife is 5 groups, each group have two knife edge.

A-2-3 Transporting System

A-3.Type: Transporting system

transport belt corresponding pressure paper, automatic tension and

close system.

A-2-4 Paper collecting system

A-4 Type: Paper collecting system

1) Automatic device for paper stack up and down

2) Jogging device and clap paper tidy. Control by air vat, when design sheet, the cylinder up and down by cut paper bar. After transport paper to belt, transport to the pack table cross.

B. RYHM-1B Wrapping Machine

B-1. Main Technical Parameters:

B-2. Configuration:

C. All the machine is controlled by PLC.

Included the following function: speed control, paper count, paper ream output, fault alarm and automatic stop (Indicate fault code shown on the panel screen).

D. Prepare items by buyer

1) The civil engineering and substructure of this machine

2) The machine main power wiring and electric line setting work out of this machine control box.

3) Air pressure source and pipe for this machine.

4) The suspend and unload work at scene.

E. Other terms

This machine design by the newest technical and technology development, so in the ruler of not effect the production and quality, we remain the right to modify and change.

*****************************************************************We have more than 20 years' experience in manufacturing corrugated cardboard production machine field.

Top quality, Competitive price, Timely delivery and Heart-to-heart service.

Your Best Partner in China!!