Automatic Die Cutting Machine for EMI Shield Foam

Kunshan Dapeng Precision Machinery Co., Ltd.- Species:Automatic Die Cutting Machine for EMI Shield Foam

- Imprinting Type:Platen

- Placing Form of Template:Horizontal

- Die Cutting Tool:Metal Mold

- Computerized:Computerized

- Automatic Grade:Automatic

Base Info

- Model NO.:DP-40Tons

- Application:Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials, Earthquake Products

- Cutting Size:650X600mm,800X600mm

- Color:Grey ( Blude , White etc)

- Transport Package:Wooden Case

- Specification:650X600mm 100*800mm etc

- Trademark:DAPENG

- Origin:Jiangsu Suzhou

- HS Code:844110000

- Production Capacity:30 Set Every Month

Description

Basic Info.

Model NO. DP-40Tons Application Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials, Earthquake Products Cutting Size 650X600mm/800X600mm Color Grey ( Blude / White etc) Transport Package Wooden Case Specification 650X600mm 100*800mm etc Trademark DAPENG Origin Jiangsu Suzhou HS Code 844110000 Production Capacity 30 Set Every MonthProduct Description

Automatic Die Cutting Machine for EMI Shield FoamAutomatic Die Cutting Machine USE AND CHARACTERISTICS

1. The machine is applicable to full-broken and or semi-broken continuous cutting operation of nonmetal rolled materials of same specifications and large batches with width smaller than 1000mm by laser wood die cutter.

2. The machine is controlled by PLC, and operated by displayer (text displayer), and is provided with automatic feeding device, which is accurate to locate and saves raw materials.

3. Hydraulic die cutting device is adopted with four-column guiding, large pressure, accurate die cutting and stable operation.

4. Belt type conveying is adopted. The materials are input from one end of machine and after die cutting and mark pressing, output from the other end of machine. He workers need only to pick up the finished materials, which has greatly enhanced production efficiency.

5. The operation surface of cutting area is installed with photoelectric protection device, which can guarantee personal safety of operators.

6. The feeding part of the machine is allocated with tension control device, which makes materials maintain tension status during transportation and prevents materials from running off center.

Products of special specifications can be customized.

Application

Used for cutting pvc, fabric, cardboard, rubber, sponge, bag, non woven, and other non-metallic materials in various industries;

Extremely suitable for cutting multiple layers of material at one time;

| Model | Working Area | Max Tonnage | Max Feeding Width | Drive Motor | Weight | Outline Dimension | Position Accuracy | Power |

| DP-650 | 650mm*600mm | 40t | 650mm | 7.5HP/5.5KW | 3 Ton | 1940mm*1500mm*1790mm | ±0.01 mm | 380V 50HZ |

| DP-650 | 850mm*600mm | 40t | 850mm | 10HP/7.5KW | 3.4Ton | 2140mm*1500mm*1790mm | ±0.01 mm | 380V 50HZ |

| DP-650 | 1000mm*800mm | 80t | 1000mm | 15HP/11..2KW | 4.5Ton | 2290mm*1500mm*1790mm | ±0.01 mm | 380V 50HZ |

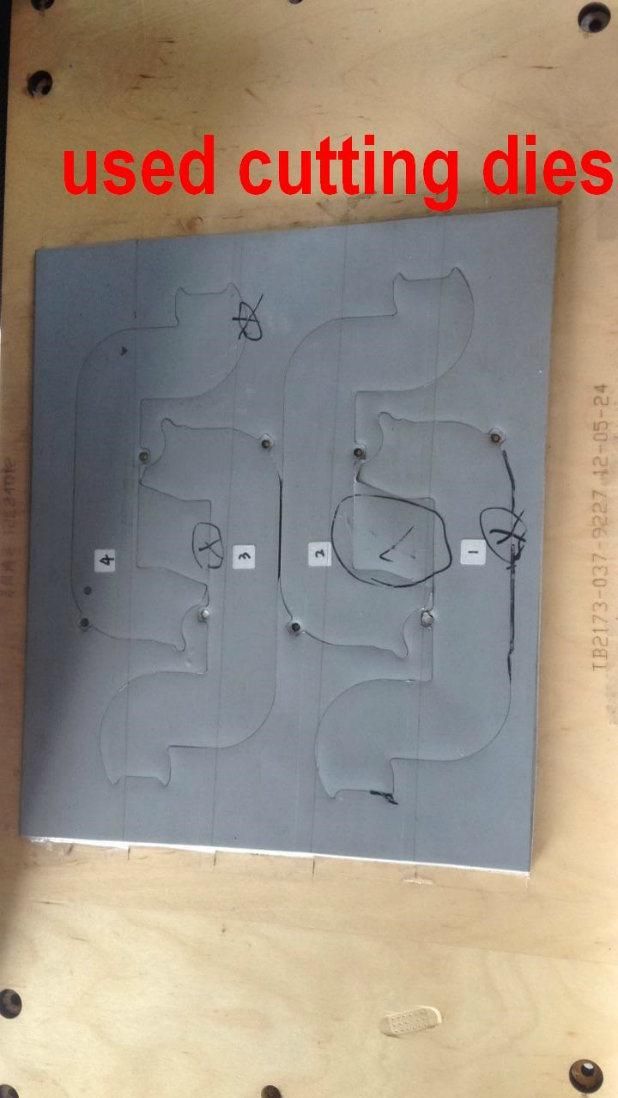

Mould sample :

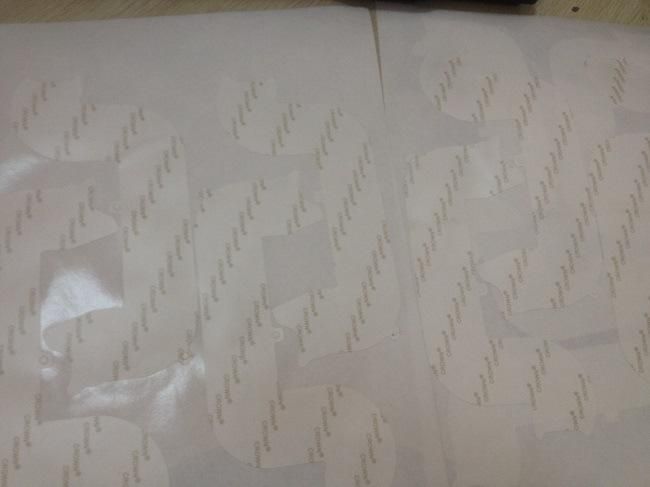

products sample

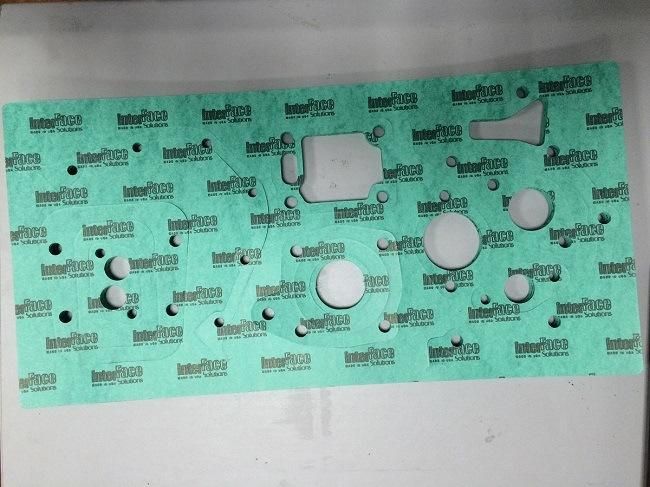

Gaskets sample :