High Speed and High Interface Offset UV Curing Tunnel Drying Machine

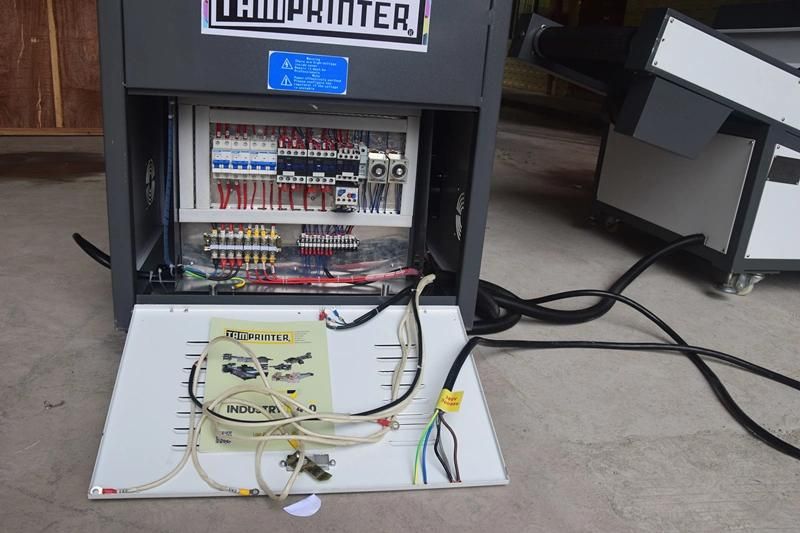

Shenzhen Tamprinter Printing Machinery Co., Ltd.- Power:380V 3phase

- UV Lamp:4PCS*8kw

- Insert Width:1100mm

- Distance From Belt to Ground:820mm

- Dimensions:400*135*145cm

- Offset Print Speed:6500 PCS,H

Base Info

- Model NO.:TM-UV-F3

- Type:UV Dryer

- Transport Package:Plywood Case,Wooden Case,as Required

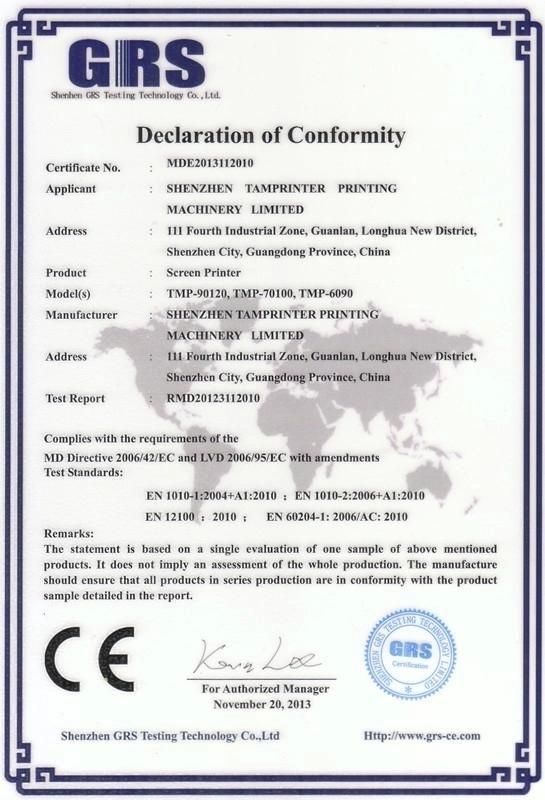

- Specification:CE

- Trademark:Tamprinter

- Origin:China(Mainland)

- HS Code:8443911900

- Production Capacity:50sets,Month

Description

Type

(mm)

(Kg)

(pcs/h)

Insert width(mm): ?

Distance from belt to ground: ?

Weight(Kg): ?

Electric control box size Body size: ?

Offset print speed (pcs/h): ?

Dimension: outline size customized according to your offset printing machine,

Butt paper receiving port width height and depth size etc., then to determine the size of UV machine. you must provide 2D drawing.

UV drying equipment can be redesigned according to your specific requirements.

Features:

(1) With teflon or stainless street net, trasmit speed steady and can be adjusted (0-70m).

(2) With two UV lighting tubes, can turn on the light according to the need.

(3) Wink-dry make the surface of the stocks high hardness and rub resistance.

(4) Tunneling-based make the whole machine light barrier good and without harm.

(5) Equipped with powerful nether induced draught system and big intake airway, can absorb the stock on the mesh belt hard.

(6) Can be used with production line and other equipment easily.

Quality, special design, and advantages of main parts:

(1)Adopt imported UV light tube, and have long useful time, and more stable wavelength.

(2)Adopting glisten film made in Germany and installing specially designed focused lampshade can promote UV energy effectively, and make the solidifying ability of the machine stronger.

(3)Exclusive design of ultralow temperature of irradiated area makes printing heat sensitive paper, film, and 0.05mm thin film not become deformed, and reprint exact.

(4)The machine adopts specially designed heat removal system, drops off UV heat, and also does not lower UV energy, makes materials stable, does not float, stop, trap in the light chest

(5)Light source is divided into bright light, middle light, and dim light, unattached switch allocating energy-saving leakage transformator produced by the factory make the energy of UV light exert to the highest-level, meanwhile save electric power changes.

(6)The machine is equipped with transformer and overtemperature protection device of lighting tube.

(7)Divided design (fuselage is separated from mainframe) is easy to operate, and can be pushed.

(8)The machine prints with printing machine at the same time: discharge velocity of rapid solidifying is 70m per minute(mph 6000 pieces of paper).

(9)The machine has many types, and can be made to order according to the requirements of customers, the solidifying speed is 5-70m/min and can be adjusted.

About Us:

Tamprinter Printing Machinery Group Limited

As one of the most professional special printer supplier of Plastic Field in China,we have supplied OEM service for the domestic counterparts since 2003. OEM products have been achieved CE certification.

Due to business expansion, Tamprinter printing machinery limited International trade department have been separated from the parent company in March 2013.

Key products : Pad printer, Screen printer, UV curing machine, Heat transfer machine.

Advantages:

1. All the electrical components and control system are from Germany and Japan, guarantee the stable quality of the print.

2. Multipurpose microcomputer operating panel and touch screen operation can easily achieve man-machine dialogue.

3. As high quality steel frame structure and High temperature of the lacquer that bake, so that our printer is light and solid, beautiful and practical.

Applications

It mainly applies to the printing process and pre-postpress of plastic and hardware products .Our equipment is also applicable to other material as glass, ceramic, wood, leather, cloth, etc.

Involved in the industry:

Electronics, toys, gifts, clothing, stationery, cosmetics, washing products, chemicals, food, health product, pharmaceutical and packaging etc.

Market Area:

More than 80 countries. Encluding Europe, the United States, Canada, Southeast Asia, the Middle East, etc. We cooperate with Omron, Emerson and Ruigao light, which are the world famous enterprises.

Our company's certifican and honor.

Welcome to contact us if you have any question!

other type