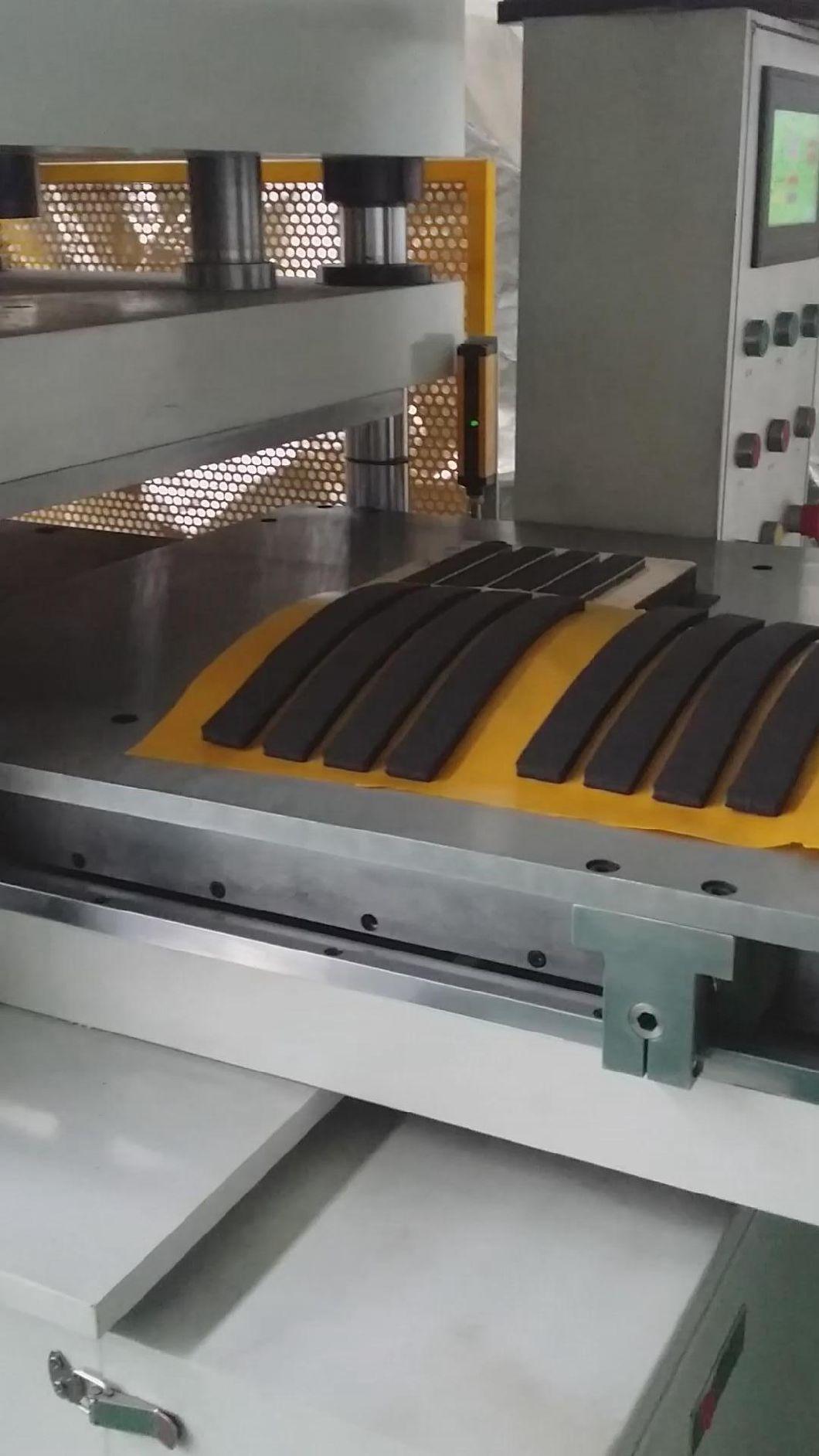

Die Cutting Machine for Sponge/Foam

Kunshan Dapeng Precision Machinery Co., Ltd.- Species:Die Cutting and Creasing Machine

- Imprinting Type:Platen

- Placing Form of Template:Horizontal

- Die Cutting Tool:Steel Plate

- Computerized:Computerized

- Automatic Grade:Automatic

Base Info

- Model NO.:DP-650P

- Application:Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials

- Name:Die Cutting Machine for Sponge,Foam

- Function:Die Cutting

- Cutting Type:Flatbed Die Cutting Machine

- Cutting Speed:20-90 Punches Per Minute.

- Precise:0.10mm

- Working Plane Dimension:650*600mm, 800*600mm, 1000*600mm

- Table Height:110mm

- Max Spacing:100mm

- Max Range:100mm

- Customize:Acceptable

- Transport Package:Wodden Case

- Specification:40t, 60t

- Trademark:Dapeng Machinery

- Origin:Kunshan, Jiangsu, China.

- HS Code:8441100000

- Production Capacity:50 Set,Sets Per Month

Description

Basic Info.

Model NO. DP-650P Application Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials Name Die Cutting Machine for Sponge/Foam Function Die Cutting Cutting Type Flatbed Die Cutting Machine Cutting Speed 20-90 Punches Per Minute. Precise 0.10mm Working Plane Dimension 650*600mm, 800*600mm, 1000*600mm Table Height 110mm Max Spacing 100mm Max Range 100mm Customize Acceptable Transport Package Wodden Case Specification 40t, 60t Trademark Dapeng Machinery Origin Kunshan, Jiangsu, China. HS Code 8441100000 Production Capacity 50 Set/Sets Per MonthProduct Description

Die Cutting Machine for Sponge/Foam

Functional Characteristics:

1.Driven by hydraulic pressure generated by motor, adopts advanced dual oil cylinder and hydraulic circuit,causes low heat while operates at a speed of more than 150mm per second;

2.Hydraulic pressure actuation of 1-14MPA, three-phase alternating current supply, AC380V 50HZ or AC220 60 HZ, total consumptions of electricity of less than 3.7KW(Power supply as per customer request also).

3.The frame adopts integrity welding technology with better regidity and stability of machine while wide convenient operation space;

4.Pressing force, stroke of cutting, dwell time, die height could be adjusted manually comply with practical demand;

5.Intelligent functions: intelligent counter, force measurement monitor, intelligent temperature controller(Customized available).

6.Range of output force: 15ft-100ft.(Optionally).

Main Technical Parameters:

(Technical parameter can be customized according to your special need ):

1.The upper beam and cutting bed are the same size that is large enough for cutting foam .

2.The cutting die can be mounted up or down.

3.The central oil supply automatic lubricating system guarantees machine precision and prolongs service life of machine.

4.Material feed systems can handle rolls or sheet format, automatic or manual operations.

5.Any specifc requirement of production can be custom built.

| Model | Working Area | Max Tonnage | Max spacing | Drive Motor | Weight | Outline Dimension | Position Accuracy | Power |

| DP-650P | 600mm*650mm | 40t | 100mm | 10HP/7.5KW | 2.8 Ton | 1300mm*1200mm*1800 mm | ±0.01 mm | 380V 50HZ |

| DP-650P | 600mm*800mm | 40t | 100mm | 10HP/7.5KW | 3.1Ton | 1300mm*1450mm*1800 mm | ±0.01 mm | 380V 50HZ |

| DP-650P | 600mm*1000mm | 60t | 100mm | 10HP/7.5KW | 4.2Ton | 1300mm*1700mm*1800 mm | ±0.01 mm | 380V 50HZ |

Control Panel :