Automatic High Speed Cardboard to Cardboard Laminator Machine (BKJ1307)

Tangshan Jiasun Import and Export Co., Ltd.- Type:Packaging Machine

- Driven Type:Electric

- Automatic Grade:Automatic

- Packaging Material:Metal

- Packaging Type:Pallet

- Application:Cardboard

Base Info

- Model NO.:BKJ1307

- Max. Sheet Size:1270*720

- Min Paper Size:500X380

- Thickness of Face Paper:100-800

- Thickness of Bottom Paper:200-2000

- Speed:150meters,Hour

- Precision:Within 0.5mm

- Power:3~380V(50Hz)

- Operation Space:3000X13500

- Total Length:10500

- Total Weight:9000kg

- Transport Package:Plastic Film

- Specification:ISO9001 & CE

- Trademark:JUXING

- Origin:China

- HS Code:8439300000

- Production Capacity:10 Set,Month

Description

Basic Info.

Model NO. BKJ1307 Max. Sheet Size 1270*720 Min Paper Size 500X380 Thickness of Face Paper 100-800 Thickness of Bottom Paper 200-2000 Speed 150meters/Hour Precision Within 0.5mm Power 3~380V(50Hz) Operation Space 3000X13500 Total Length 10500 Total Weight 9000kg Transport Package Plastic Film Specification ISO9001 & CE Trademark JUXING Origin China HS Code 8439300000 Production Capacity 10 Set/MonthProduct Description

- Specifications

| Model | BKJ 1307 | BKJ1310 | BKJ1410 |

| Max. Sheet Size (WxL) | 1270mmx720mm | 1270mmx1000mm | 1410mmx1410mm |

| Min. Sheet Size (WxL) | 500mmx380mm | 500mmx400mm | 500mmx400mm |

| Thickness of Upper Paper | 100~800g/ | 100~800g/ | 100~800g/ |

| Thickness of Bottom Paper | 200~2000g/ | 200~2000g/ | 200~2000g/ |

| Max. Speed | 150Meters/Min | 120Meters/Min | 120Meters/Min |

| Lamination Precision | ±0.5mm | ±0.5mm | ±0.5mm |

| Total Weight | 9000kg | 9000kg | 11000kg |

| Total Length | 10500 | 10500 | 12000 |

| Operation Space | 3000x13500 | 3000x13500 | 3000x13500 |

| Power | 3~380V(50Hz) | 3~380V(50Hz) | 3~380V(50Hz) |

- Main features of the machine

- High precision: ±0.5mm which can make the latter process more easy to achieve.

- High speed: 150 pieces per minutes

- Wide range of application: 100-800g face paper and 200-2000g bottom paper can be used on the machine.

- Glue saving: it can save 5g/m2 with the unique anilox roller

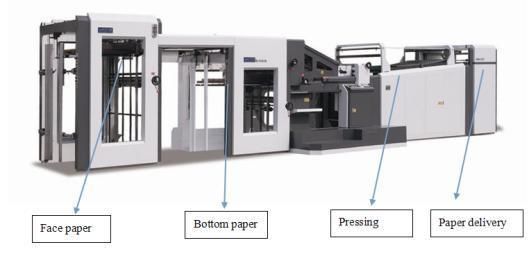

- Introduction of The Machine:

- Function of the machine:

- Structure:

Lower Feeder: 200-2000 gsm paper

Compressor: Compress the laminated paper and conveying them to the piling part.

Paper piling part: To pile the laminated paper

Gluing Part: To glue on the bottom paper

Registration Part: To ensure precise paper lamination.

Features By Part;

a) Feeding part

The machine adopts mature high speed feeding structure with simple operation, easy

maintenance which can fit to various kinds of paper.

- Four sucking and five forwarding which can do feeding of thin paper and wrapped paper.

- Double sucking rubber and single rubber forwarding which can avoid effectively double paper.

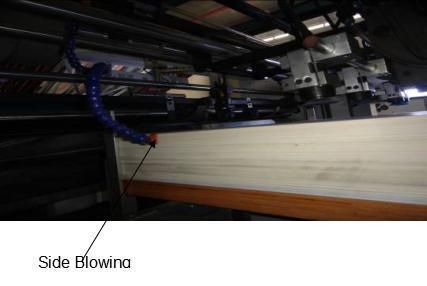

- Equipped with two blower to ensure paper separation smoothly.

- Side blower

- Registration Adjustment:

- For the in lamination, you can adjust the wheel according to the number it shows.

- The registration of lamination can be done when the paper is running. When fine adjustment is needed, you can only press related button to do the adjustment.

- The registration of the piling can be achieved by pressing the related buttons on the panel.

- Both of the pressure and glue volume adjustment is easy to achieve by turning the adjustment wheel. You can record down the number in case you have the same paper size latter.

- Three pressing belt to ensure smooth running of the paper

- Special pressing roller to insure high precision

- Paper Jam detector is equipped after lamination.

- To protect paper roller with the roller, 6 anti-roll device is equipped with the machine.

- Two washing rollers are equipped with the machine, one is under gluing roller and one is under pressing roller to keep clean of the paper

- Anilox roller makes the glue consumption even and less ( PVA is test for 30 gsm)

- Bearings are NSK

- Good Vacuum Pump

- Siemens Motor

- Taiwan Chengpang Reducer

- Man-machine interface

- Main Cabinet

- Baumer Detector

- PLC

- Paper after lamination:

- Machine Dimension

| L*W*H | |

| Main 1 | 1500x2450x2350 |

| Main 2 | 5200x2450x2200 |

| Compressing part | 4100x2000x2150 |

- Other information:

- The above price is based on FOB Tianjin, China.

- The enclosed pictures are just for reference, kindly please make the specification and object as the standard.

- As for the overseas installation, the customer shall pay each installation person 50.00USD per day and bear the costs of air trip tickets, food and accommodation.

- The fabrication period is within 120 days and the installation period within around 15 days after the advance payment received.

- 30% advance payment paid by T/T before fabrication and 70% balance payment before delivery.

- The machine above needs a 40HQ container.