China Manufacturer Operating Easily Automatic Paper Facial Tissue Folding Machine

Liuzhou Zode Machinery Sci-Tech Co., Ltd.- After-sales Service:Engineers Available to Service Machinery Overseas,

- Warranty:1 Years

- Classification:Professional Folding Machine

- Folding Type:Double Parallel Fold

- Paper Inputting Type:Continuous Feeding

- Type:Paper Folding Machine

Base Info

- Model NO.:ZD-B-90

- Computerized:Computerized

- Automatic Grade:Automatic

- Folding Mechanism:Hinge Roll

- Structure:Folding

- Model No.:Zd-B-90

- Production Speed:120 Meter,Min.

- Power:3 Phase, 380V,50Hz,

- Machine Weight:Machine Weight

- Overall Dimension:6000*2300*1920 mm

- Host Power:7.5 Kw

- Vacuum System:22 Kw Roots Vacuum System

- Controller:Frequency Control

- Cutting System:Point Cut by Pneumatic Type

- Color:White or Custom

- Transport Package:Packed in Wooden Cases

- Specification:3513mm*3023mm*1650mm

- Trademark:zode

- Origin:China

- HS Code:8422303090

- Production Capacity:20 Set,Sets Per Month

Description

1) Adopt PLC & HMI control system, easy to operate,

2) Each unit is driven by independent motor, could easily adjust web tension of each position

3) Independent wall-type back-stand, structure is simpler and stronger, easy to clean.

this model is designed to produce `link type head of next sheet will come out the box. And this machine can produce either embossed or without embossed for customers' selection. It has a feature of tight structure, easy operation, stable operation and elaborate designed.

We can make the machine with 4lines 5 lines and 6 lines.Production Lines generally use 6 lines and7 lines.9linse

Main performances and structure features:

1.Packing forms such as automatic feeding, box opening, boxing, batch No. printing, glue spreading, box sealing, etc. are adopted. Featured by compact and reasonable structure, simple operation and adjustment.

2. Servo/step motor, touch screen, PLC control system and man-machine interface display make operation more clear and convenient. With high automation degree, the machine is more user-friendly.

3. The automatic material arranging and conveying mechanism is adopted to facilitate linked production with automatic production line, which can greatly reduce labor cost.and sizes can be realized.

4. The photoelectric eye automatic detection tracking system is adopted. No boxing is made if the bag is empty, so as to save packing materials to the utmost extent.

5. With wide packing range and convenient adjustment, fast switching among various specifications

6. Change of specifications does not need change of molds, but can be realized through adjustment.

7. Automatic stopping is available when the material boxing is not in place, and the main driving motor overload protection device is used, so that the machine is safer and more reliable.

8. According to customer requirements, the upturning type safety protective cover is adopted, which is featured by simple operation and beautiful appearance.

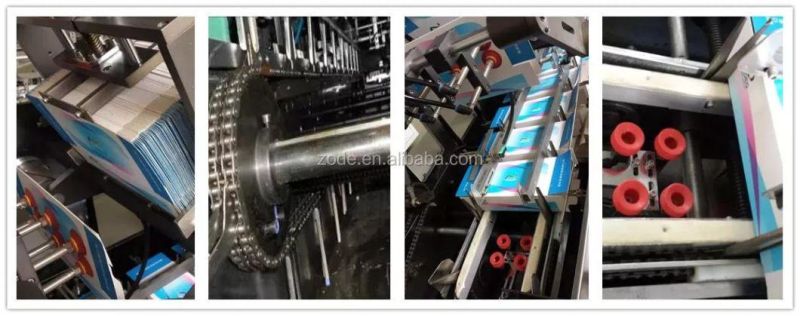

Machine details:

Packing & DeliveryPackaging

Packing & DeliveryPackaging• Cover with plastic film.

• Packed with wood tray or wood case, it depends on the machine model.

Delivery terms:

• 30% with the order as down-payment.

• 70% after machine completion, but before shipment.

• Will finished manufacturing in 60days after received the down-payment.

Our ServiceOur company

Our ServiceOur companyLiuzhou Zode Machinery Sci-Tech Co., Ltd..

Liuzhou Zode Machinery Sci-Tech Co., Ltd. is a a professional high technology company. As a leading manufacturer and exporter of tissue paper machinery in China. Serve the facial tissue converting and packing production line, toilet tissue and kitchen towel rewinding and packing production line, hand towel folding and packing production line around the world. Our main market is Europe and America, Middle East, South America. Fexik Machinery had passed international certification ISO9001 and several national invention patents, with full independent intellectual property rights. Our strength is our powerful research and development team that can rapidly customize unique solutions to meet the ever-changing market demands and special requirements from customers. We can provide solutions to customers from products choosing, designing, installing and training. From upfront engineering to ongoing technical support, our designs are focused on meeting the regulations of human and product safety as well as the environment in every market that we serve.