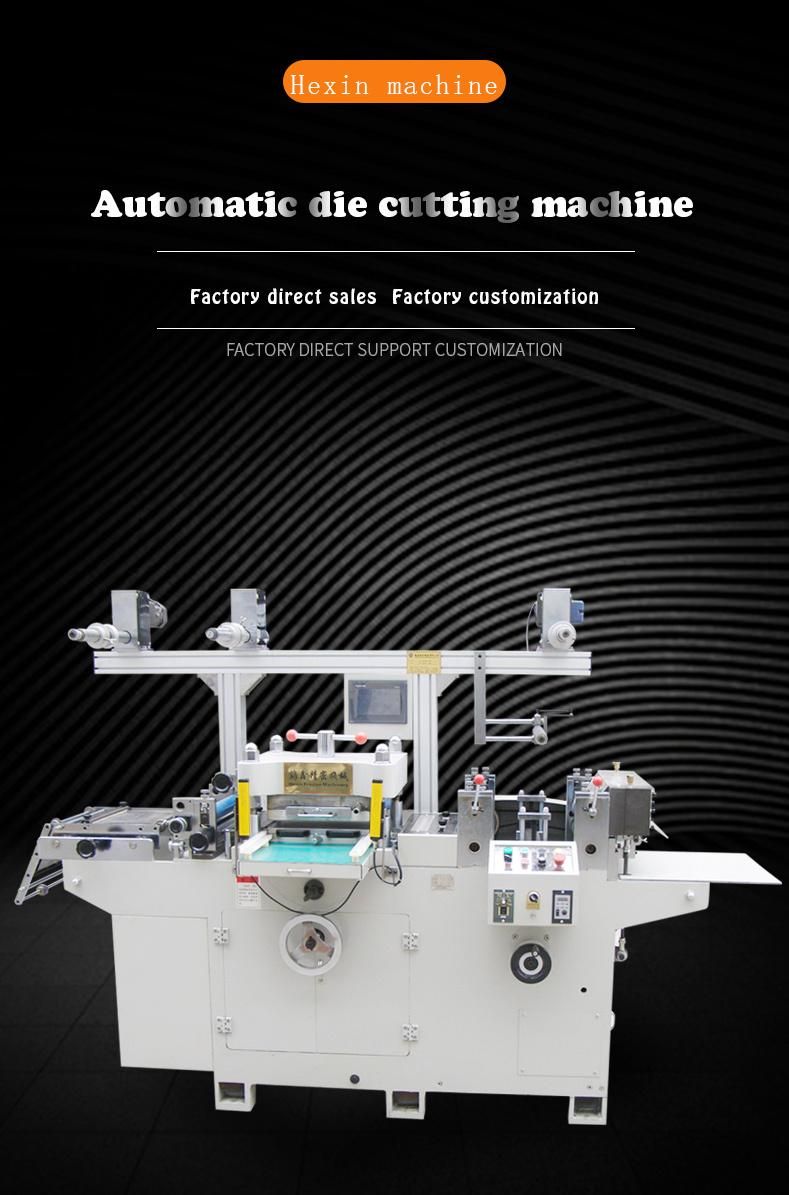

Insulating Materials and Creasing Hexin Die Cutting Automatic Die-Cutting Machine

Kunshan Hexin Precise Machinery Co., Ltd.- After-sales Service:Online

- Warranty:1year

- Species:Die Cutting and Creasing Machine

- Imprinting Type:Platen

- Placing Form of Template:Horizontal

- Die Cutting Tool:Steel Plate

Base Info

- Model NO.:HX-320B

- Computerized:Computerized

- Automatic Grade:Automatic

- Application:Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials

- Model:Hx-320b

- Cutting Speed:20-200t,Min

- Max. Unwinding Diameter:450mm

- Max Web Width:320mm

- Max Mould Cutting Area:0.10mm

- Orientation Accuracy:4kw

- Motor:4kw

- Machine Weight:2800kg

- Measurement:2600*1050*1800mm

- Transport Package:Plywood Case

- Specification:CE ISO

- Trademark:HEXIN

- Origin:China Jiangsu

- Production Capacity:200 Sets, Month

Description

Basic Info.

Model NO. HX-320B Computerized Computerized Automatic Grade Automatic Application Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials Model Hx-320b Cutting Speed 20-200t/Min Max. Unwinding Diameter 450mm Max Web Width 320mm Max Mould Cutting Area 0.10mm Orientation Accuracy 4kw Motor 4kw Machine Weight 2800kg Measurement 2600*1050*1800mm Transport Package Plywood Case Specification CE ISO Trademark HEXIN Origin China Jiangsu Production Capacity 200 Sets/ MonthProduct Description

Printed Label Aluminum Foil Plastic Die Cutting Machine Automatic foam Paper vinyl Sticker Rubber Laminate Flat label Die Cutting Machine price

Automatic foam Paper vinyl Sticker Rubber Laminate Flat label Die Cutting Machine price This machine integrates multi-layer lamination and partial lamination, and the discharge-film-die cutting-waste

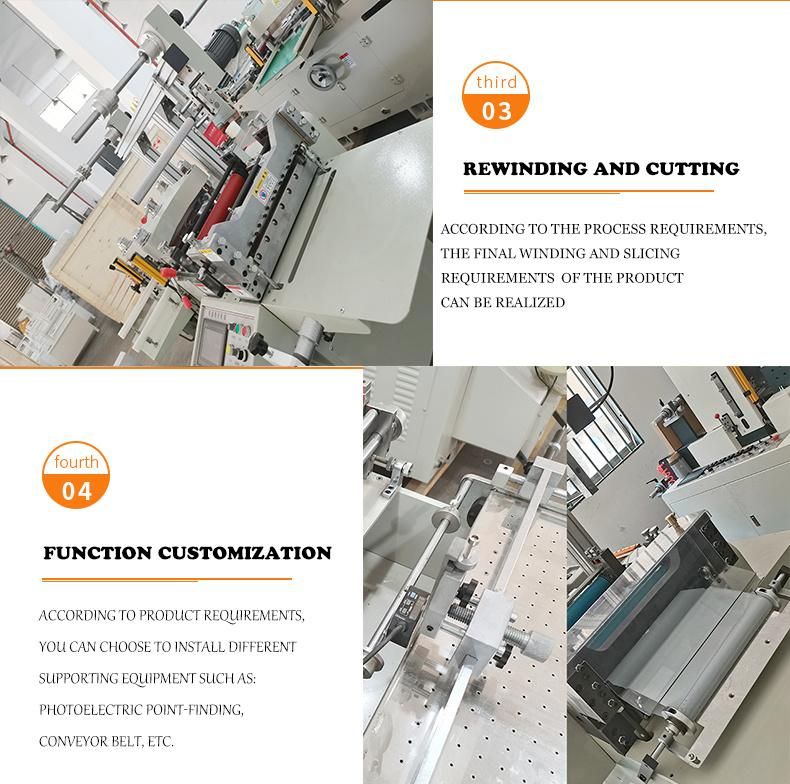

This machine integrates multi-layer lamination and partial lamination, and the discharge-film-die cutting-wastedischarge-slicing-rewinding is controlled by a computer at one time.Features:

Multi-function in ONE machine: Laminating / partial laminating+unwinding+laminating+die cutting +discharging sheet

cutting/rewinding

Photo Cell if necessary .Sucking device during material feeding process

Waste discharge shaft. Sheet cutting station

Rewinding station .Safety curtain device

Optional function: Conveyor belt device for full-cut use

Application:

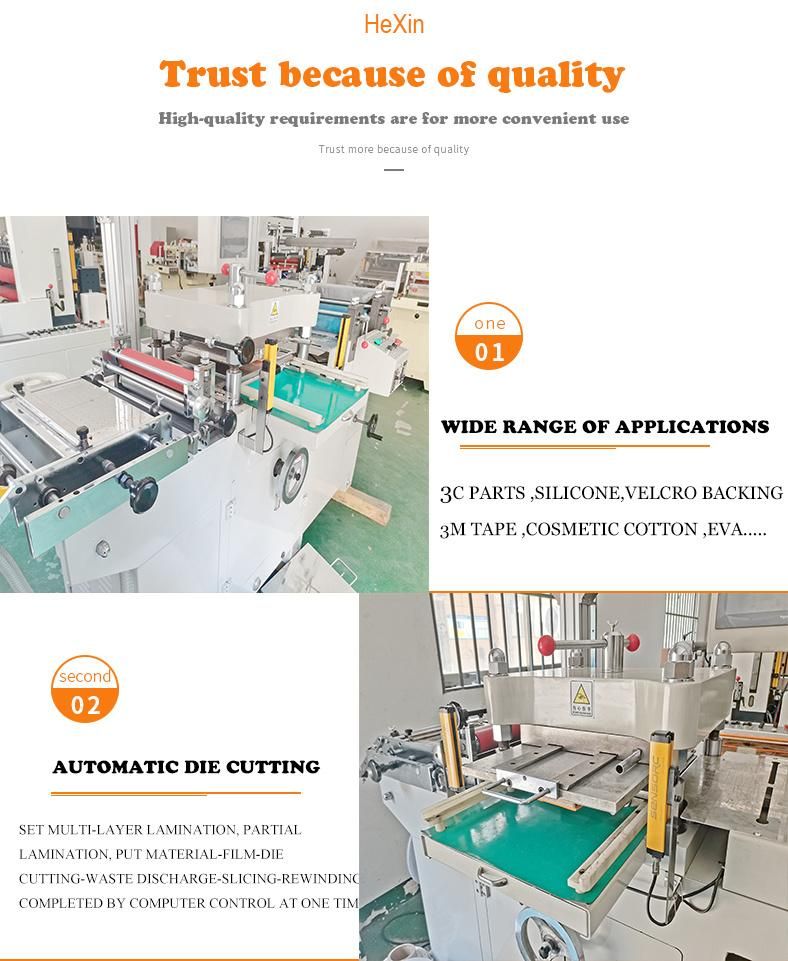

Glue-based products: 3C parts, foot pad, silicone, velcro backing, conductive tape, double-side tape,3M tape and all kinds of glue-based products.

Dustproof materials: cosmetic cotton, camera cotton, high density sponge, filtering sponge, dustproof filter, non-woven fabric,etc.

Shockproof materials: EVA tape, rubber cushion, PORON cushion,3M, flame-resistant EVA, EPDM,etc.

Insulation/shielding materials : EMI Shielding material, fireproof paper, aluminum foil, copper foil, PVC,PET, k paper, sponge sheath, pearl cotton sheath and so on.

Heat-conductive/ heat-proof materials : silicon sheet, transparent mica, fiber cloth, heat insulation cotton and so on.

Other materials which are suitable for die cutting

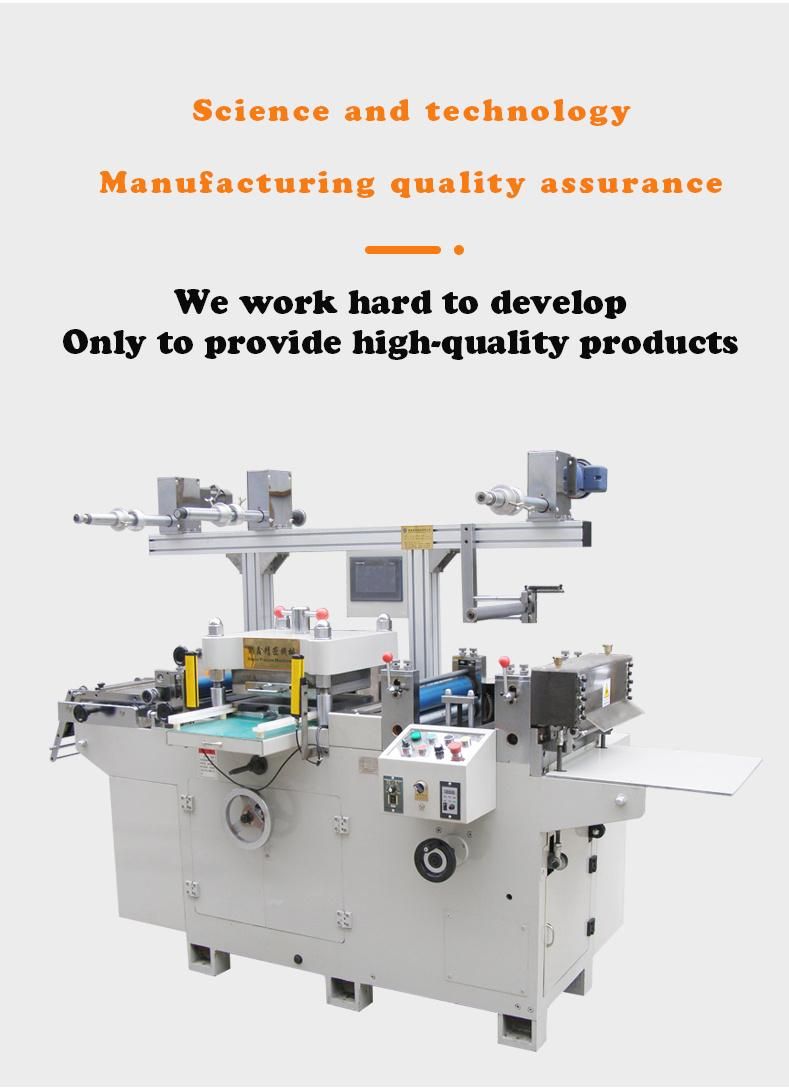

The working principle of the flat die-cutting machine is: the product model that has been opened according to the product drawing in advance is stamped into the specified shape by means of upper and lower stamping. The entire operation process of the die-cutting machine is driven by the servo motor to pull the material to drive the automatic feeder to feed. , Passing through the feed can complete some actions of the film, passing through the die-cutting machine of the die-cutting machine, draining the waste of the frame, and cutting into pieces to complete some of the entire process. Compared with other die-cutting equipment, the flat die-cutting machine has the advantages of convenient operation, convenient maintenance,easy replacement of die-cutting indentation plates, suitable for materials of different weights, and precise die-cutting, so it has been widely used

The working principle of the flat die-cutting machine is: the product model that has been opened according to the product drawing in advance is stamped into the specified shape by means of upper and lower stamping. The entire operation process of the die-cutting machine is driven by the servo motor to pull the material to drive the automatic feeder to feed. , Passing through the feed can complete some actions of the film, passing through the die-cutting machine of the die-cutting machine, draining the waste of the frame, and cutting into pieces to complete some of the entire process. Compared with other die-cutting equipment, the flat die-cutting machine has the advantages of convenient operation, convenient maintenance,easy replacement of die-cutting indentation plates, suitable for materials of different weights, and precise die-cutting, so it has been widely used Die-cutting machines are also called beer machines and CNC punching machines. They are mainly used for die-cutting (full-break, half-break) and pressing of corresponding non-metallic materials, stickers, EVA,double-sided tape, electronics, mobile phone pads, etc. Marking and bronzing operations, laminating, automatic waste discharge,the die-cutting machine uses steel knives, metal molds, steel wires (or stencils carved from steel plates), and applies certain pressure through the embossing plate to cut the printed products or cardboard into Certain shape. It is an important equipment for post-press packaging processing and shaping.

Die-cutting machines are also called beer machines and CNC punching machines. They are mainly used for die-cutting (full-break, half-break) and pressing of corresponding non-metallic materials, stickers, EVA,double-sided tape, electronics, mobile phone pads, etc. Marking and bronzing operations, laminating, automatic waste discharge,the die-cutting machine uses steel knives, metal molds, steel wires (or stencils carved from steel plates), and applies certain pressure through the embossing plate to cut the printed products or cardboard into Certain shape. It is an important equipment for post-press packaging processing and shaping. The working principle of die-cutting machine is to use steel knives, hardware molds, steel wires (or stencils carved from steel plates) to apply certain pressure through the embossing plate to roll and cut printed products or cardboard into certain shapes.If the entire printed product is press-cut into a single graphic product, it is called die-cutting; if the steel wire is used to make traces on the printed product or leave a bent groove, it is called indentation; Heated to a certain temperature, hot stamping of patterns or fonts with a three-dimensional effect on the surface of the printed product is called hot stamping; if one substrate is used to overlay another substrate, it is called laminating; except for the genuine product, the rest is called To discharge waste; the above can be collectively referred to as die cutting technology.

Die Cutting Machine , also known as cutting machine, CNC punching machine, is mainly used for die-cutting (completely broken) of corresponding non-metallic materials, stickers, EVA, double-sided tape, electronics, mobile phone pads, etc. , Semi-broken),indentation and bronzing operations, laminating, automatic waste removal, die-cutting machine uses steel knives, hardware molds,steel wire (or a template carved from steel plates), and applies a certain pressure through the imprinting plate to print The product or cardboard is rolled and cut into a certain shape. It is an important equipment for post-press packaging processing and forming

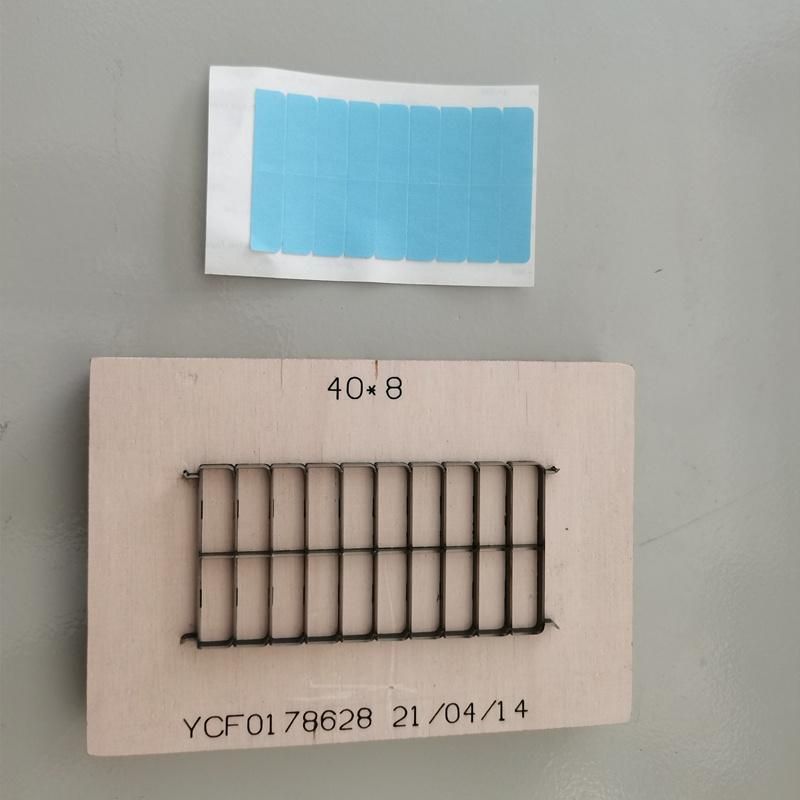

Die Cutting Machine , also known as cutting machine, CNC punching machine, is mainly used for die-cutting (completely broken) of corresponding non-metallic materials, stickers, EVA, double-sided tape, electronics, mobile phone pads, etc. , Semi-broken),indentation and bronzing operations, laminating, automatic waste removal, die-cutting machine uses steel knives, hardware molds,steel wire (or a template carved from steel plates), and applies a certain pressure through the imprinting plate to print The product or cardboard is rolled and cut into a certain shape. It is an important equipment for post-press packaging processing and forming The die-cutting process is the most commonly used process for packaging printed matter. It uses a die-cutting knife to combine the patterns required by the product design to form a die-cutting plate. Under pressure, the printed matter or other ring-packed blanks are rolled into the desired shape or The forming process of the cut marks. The creasing process is to use a crimping knife or a crimping die to make a line mark on the sheet through the action of pressure, or use a rolling wheel to bend and shape the board at a predetermined position. Usually, the die-cutting and creasing process is a process of combining the die-cutting knife and the crimping knife in the same template, and simultaneously performing die-cutting and creasing processing on the die-cutting machine, which is referred to as die-cutting.Process introduction The main process of die-cutting and indentation is:uploading→adjusting pressure→determining the rules→adhesive base material accessories→test pressure die-cutting→formal die-cutting and indentation→removing waste→finished product winding or cutting into pieces→points package

The die-cutting process is the most commonly used process for packaging printed matter. It uses a die-cutting knife to combine the patterns required by the product design to form a die-cutting plate. Under pressure, the printed matter or other ring-packed blanks are rolled into the desired shape or The forming process of the cut marks. The creasing process is to use a crimping knife or a crimping die to make a line mark on the sheet through the action of pressure, or use a rolling wheel to bend and shape the board at a predetermined position. Usually, the die-cutting and creasing process is a process of combining the die-cutting knife and the crimping knife in the same template, and simultaneously performing die-cutting and creasing processing on the die-cutting machine, which is referred to as die-cutting.Process introduction The main process of die-cutting and indentation is:uploading→adjusting pressure→determining the rules→adhesive base material accessories→test pressure die-cutting→formal die-cutting and indentation→removing waste→finished product winding or cutting into pieces→points package The working principle of the automatic flat-bed die-cutting machine is that the paper feeder feeds the paper into the front gauge and the side position through the paper feeding part, and then the paper is sent to the die-cutting mechanism by the tooth row for secondary positioning and die-cutting. After cutting, it is sent to the waste removal mechanism by the tooth row, and then enters the paper delivery section after the waste removal, thereby completing the die-cutting operation.Touch screen technology,frequency conversion speed regulation technology and programmable controller technology are widely used in the equipment, and the stability and reliability of the equipment have been greatly improved.Data communication between multiple programmable controllers of the die-cutting machine; LCD intelligent operation display screen,human-machine dialogue; use optical fiber sensor to detect the cursor, precise positioning; digital servo; holographic aluminum foil surface tension controlmachine parameters

The working principle of the automatic flat-bed die-cutting machine is that the paper feeder feeds the paper into the front gauge and the side position through the paper feeding part, and then the paper is sent to the die-cutting mechanism by the tooth row for secondary positioning and die-cutting. After cutting, it is sent to the waste removal mechanism by the tooth row, and then enters the paper delivery section after the waste removal, thereby completing the die-cutting operation.Touch screen technology,frequency conversion speed regulation technology and programmable controller technology are widely used in the equipment, and the stability and reliability of the equipment have been greatly improved.Data communication between multiple programmable controllers of the die-cutting machine; LCD intelligent operation display screen,human-machine dialogue; use optical fiber sensor to detect the cursor, precise positioning; digital servo; holographic aluminum foil surface tension controlmachine parameters Model | 320B | 420B |

Cutting speed | 20-200 (t/m) | 20-200 (t/m) |

Max unwinding diameter | 450mm | 450mm |

Max web width | 320mm | 420mm |

Max mould cutting area | 300*300mm | 420x420mm |

Orientation accuracy | ±0.10mm | ±0.10mm |

Motor power | 3kw | 4kw |

Power voltage | 220v±10% | 380v±10% |

Machine weight | 2000kg | 2800kg |

Measurement | 2500x900x1400mm | 2600x1050x1800mm |

Company Information certificationsCE Certification for leather belt cutting machine Our machines meet CE requirement . Conform to the safety, health, environmental protection and consumer protection, and a series of European directives to express requirements . For our products ,please rested assured .Letter of PatentUtility Model Patent Certificate .Thirty years of production experience ,we spent a great deal of time to research new products ,won a number of utility model patent certificates .Some of our product are world first . Our machines are widely applied in laminating, slitting and die cutting for protective materials, sticky materials, insulating materials, conductive materials, electronic materials, printing materials and so on, and sizing cutting for strings, strips, sheets, ropes, lines, belts, rolls, plates ,tubes, fibre, rubber, foam, Mylar, LCD, films, tapes, PET, PVC, PC, metal foils, etc. Our machines can process all kinds of sheet materials, roll materials and so on. we will provide all our customers with reliable products, perfect service in order to create a brilliant future together. Any help , please feel free to contact us.

Company Information certificationsCE Certification for leather belt cutting machine Our machines meet CE requirement . Conform to the safety, health, environmental protection and consumer protection, and a series of European directives to express requirements . For our products ,please rested assured .Letter of PatentUtility Model Patent Certificate .Thirty years of production experience ,we spent a great deal of time to research new products ,won a number of utility model patent certificates .Some of our product are world first . Our machines are widely applied in laminating, slitting and die cutting for protective materials, sticky materials, insulating materials, conductive materials, electronic materials, printing materials and so on, and sizing cutting for strings, strips, sheets, ropes, lines, belts, rolls, plates ,tubes, fibre, rubber, foam, Mylar, LCD, films, tapes, PET, PVC, PC, metal foils, etc. Our machines can process all kinds of sheet materials, roll materials and so on. we will provide all our customers with reliable products, perfect service in order to create a brilliant future together. Any help , please feel free to contact us.