Manual Hot Foil Stamping Machine for Paper, PVC, Cardboard, etc

ZHEJIANG GUANGYA MACHINERY CO., LTD.- Classification:Continuous Stamping Machine

- Plate Type:Letterpress

- Color & Page:Mutil Color

- Suitable Material:Paper

- Automatic Grade:Semi-Automatic

- Application:Leather Heat Transfer, Business Card, Plastic Flexible Packaging, Arts and Crafts, Labels and Tags, Cap

Base Info

- Model NO.:TYMC-203

- Usage:Label Printer, Paper Printer

- Hot Stamping Pressure Factor:Hot Stamping Temperature

- Decisive Factor:Pressure

- Type:Heat Press Machine

- Function:Die Cutting and Gilding

- Transport Package:Wooden Case

- Specification:1960mm*1760mm*2060mm

- Trademark:Shiwei

- Origin:China

- HS Code:84439119

- Production Capacity:20 Sets Per Month

Description

Basic Info.

Model NO. TYMC-203 Usage Label Printer, Paper Printer Hot Stamping Pressure Factor Hot Stamping Temperature Decisive Factor Pressure Type Heat Press Machine Function Die Cutting and Gilding Transport Package Wooden Case Specification 1960mm*1760mm*2060mm Trademark Shiwei Origin China HS Code 84439119 Production Capacity 20 Sets Per MonthProduct Description

1.Product DescriptionHot Stamping Foil Printing Machine is a kind of special equipment used for thermo-printing and creasing various products, such as cardboard, leather and plastic etc.

It is suitable for thermo-printing various paper products with electrochemical aluminum and also used as a creasing and die cutting machine for mould cutting and creasing cardboard cases and boxes. Concave-convex thermo-printing of various high-grade and fine printed products can also be conducted on this machine for obtaining stereoscopic exquisite and beautiful packing and decorating products.

The machine is controlled by a chip microprocessor. with the foil-feeding rubber roller of electrochemical aluminum driven by the separately set length and leapfrog parameters to make the most effective using of electrochemical aluminum. The purpose of this model is to ensure that the system runs stably and reliably so that the machine can be maintained easily and simply.

Introduction

1.TYMC series hot foil stamping and die cutting machine is very versatile, with the functions of hot stamping, die cutting,creasing and concave-convex forming and so on.

2. The display system with LCD screen greatly improves the productivity.

3. All the casting are treated with annealing. it will reduce the wear of machine.

4. This machine adopts PLC microcomputer control from Japan, stepper motor drive for reliable operation and convenient adjustment

5. The hot plate divided into 4 zones, and each zone can be adjusted independently.Fast heating, low-energy, constantly temperature control, real-time temperature display which will ensure high product quality.

TYMC 203 Factory real show

Basic specification

| Max.effective plate area: | 930mm*660mm |

| Max.gilding size: | 930mm*660mm |

| Group of foil feeding roller: | 3 |

| Max. length of foil feeding: | 660mm |

| Leapfogging Scope: | 0-99 |

| Heating plate zones: | 5 |

| Heating plate power: | 12.5kw |

| Total power: | 16.5kw |

| Main motor power: | 4kw, 4 pole |

| Working speed: | 25±2 sheets/min |

| Weight of machine: | 2600kg |

| Dimension: | 1960mm*1760mm*2060mm |

2.Sample

3.Payment &packaging&shipping

1) Payment: TT, 30% as deposit,balance 70% before shipment.

2) Packaging: Wooden case

3)Shipping: by sea

4.Why choose us

5.FAQ

1. Q: Are you a factory or trading company?

A: We are a factory,manufacturer.

2. Q: What certificate do you have?

A: We have ISO9001 and CE certificate.

3. Q: How dose your factory do regarding quality control?

A: We have a special QC department in charge of product's quality.

4. Q: How long is the warranty period?

A: All of our products have one year warranty.

5. Q: What's the main market of your company?

A: we have customers all over the world.

6. Q: What is your delivery time?

A: Normally, It needs about 45 days. The exact time depends on production management.

7. Q: Can we visit your machine operation in your factory?

A: We have sample of machine in our workshop, you can visit our factory to test our service and quality of

machine.

8.Q: Where is your factory located? How can we visit there?

A: Our factory located in Baihai New Zone,Pingyang County,Zhejiang province,China. You can by air to

Wenzhou Airport and by High-speed rain to Ruian Station. We will arrange to pick up you.

We are welcome all friends to visit us for future cooperation!

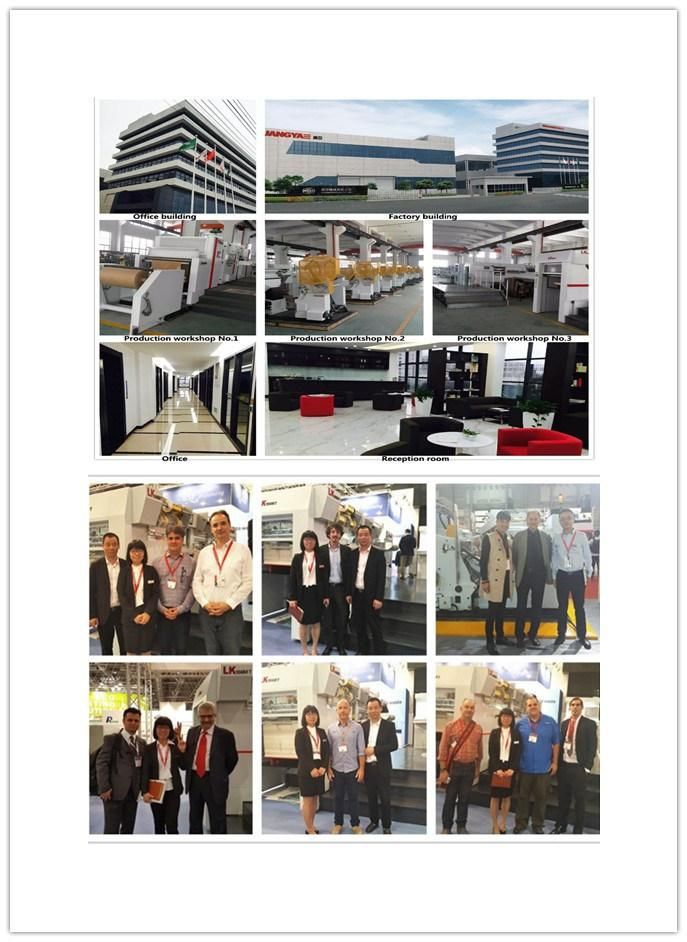

6.Company profile & Exhibiton

Zhejiang Guangya Machinery Co.,Ltd is a professional manufacturers of hot foil stamping and die cutting machine with long history.Since its establish we have always insisting on the policy of Achieved success by quality,Integrity is base,also pay attention to new product development and continual improvement.On designing machine, we adopt high and new technology from home and abroad.Our products is very popular in domestic market and already exported to over 70counteirs or region such as Europe,North America,Middle East and so on.

7.Contact person