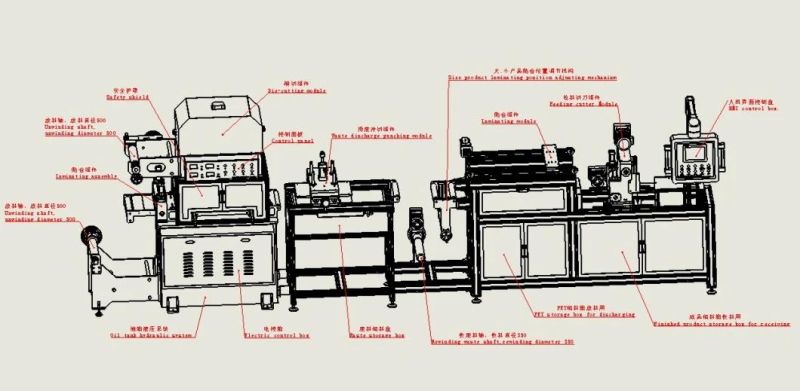

Adhesive Roll Tape Hydraulic Press

Kunshan Dapeng Precision Machinery Co., Ltd.- Species:Die Cutting and Creasing Machine

- Imprinting Type:Platen

- Placing Form of Template:Horizontal

- Die Cutting Tool:Steel Plate

- Computerized:Computerized

- Automatic Grade:Automatic

Base Info

- Model NO.:DP-400DC

- Application:Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material

- Name:Hydraulic Press Die Cutting Machine

- Max Feeding Width:400mm

- Die Cutting Area:400*500mm

- Cutting Force:18 Tons

- Unwinding Shaft Type:3 Inch Air Shaft

- Transport Package:Wooden Case, Die Cutting Machine

- Specification:CE

- Trademark:DP

- Origin:Kunshan, Jiangsu, China.

- HS Code:8477800000

- Production Capacity:10 Sets,Year

Description

Product Pictures:

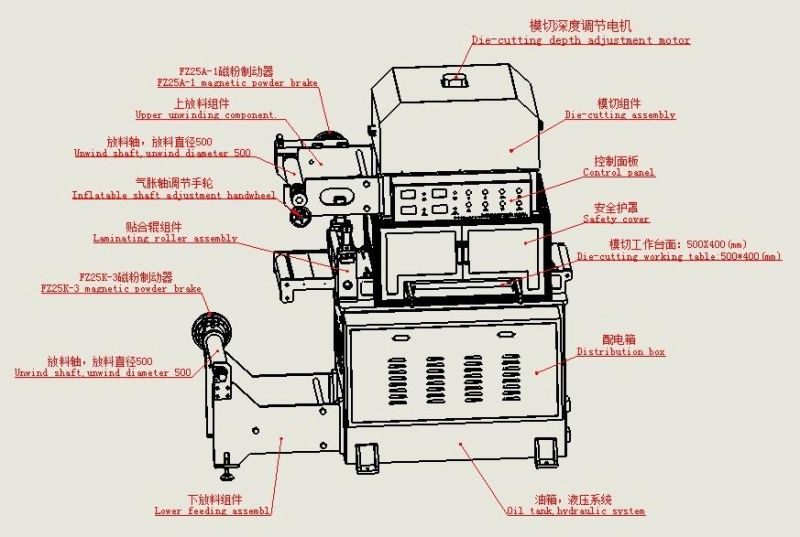

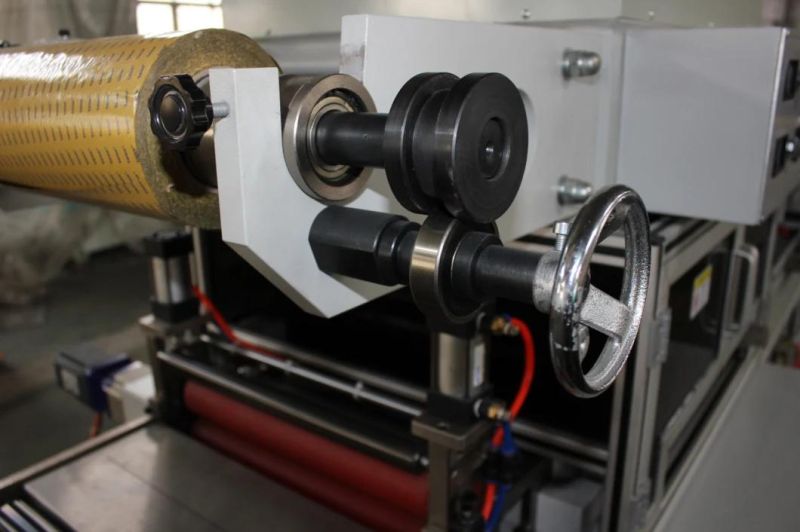

1.Die cutting components: Unwinding:3 inch inflatable unwinding shaft,unwinding diameter 500MM, magnetic powder brake to control the tension.

Unwinding:3 inch inflatable unwinding shaft,unwinding diameter 500MM, magnetic powder brake to control the tension.

by adjust the upper unwind handwheel,the laminating position of the up material can be left and right adjusted slightly.

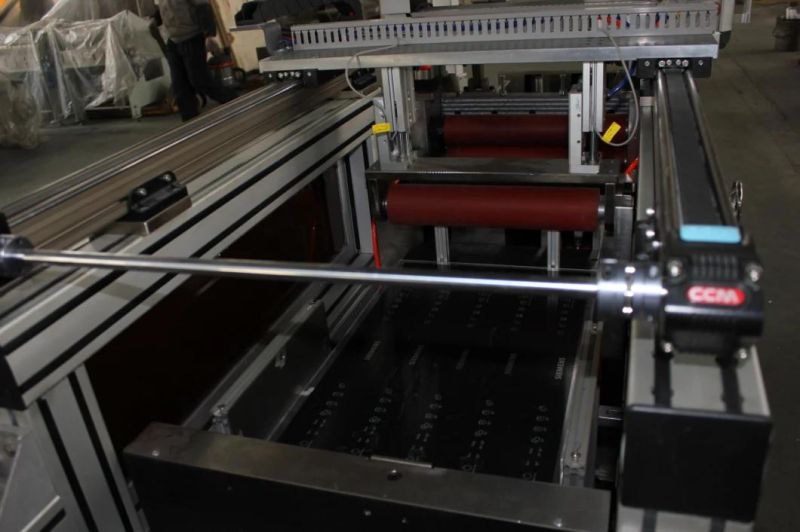

Laminating:Servo motor pull the laminating roller,high precision,the cylinder controls the upper roller up and down.

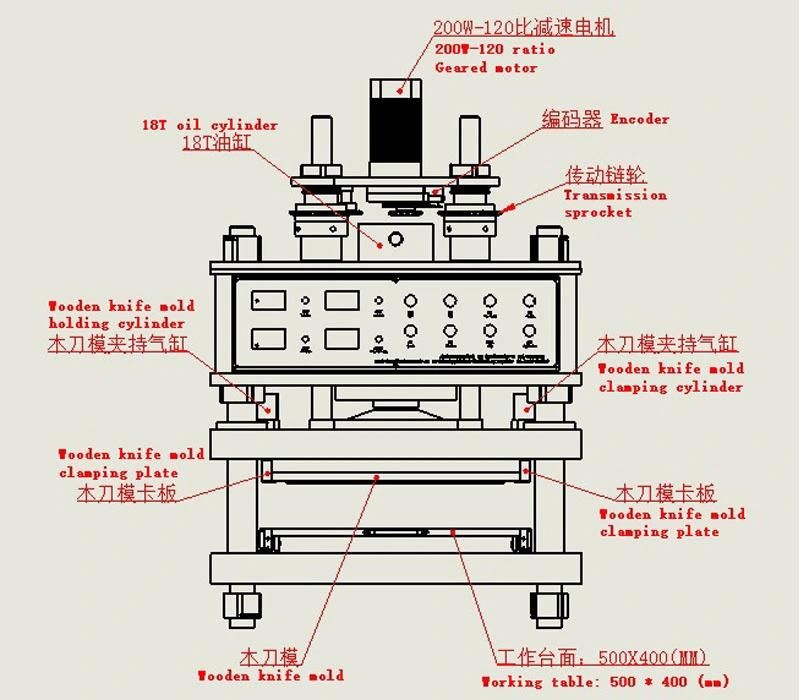

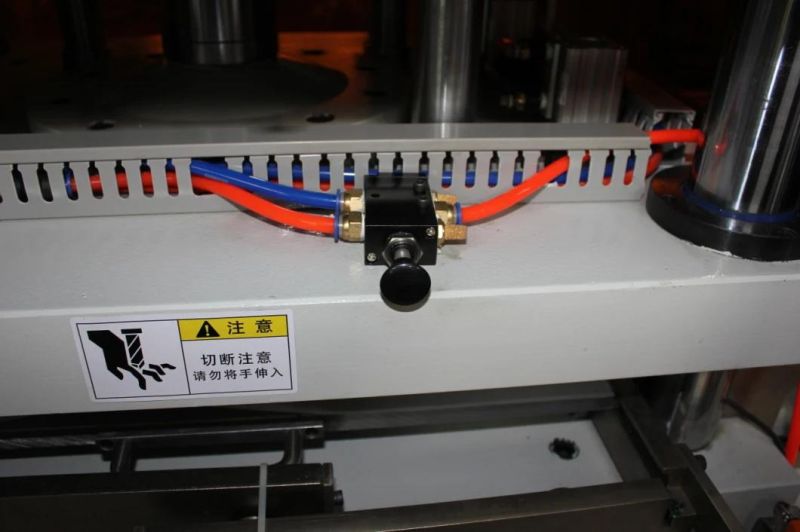

Die cutting:Die cutting using 18T hydraulic cylinder,the die-cutting depth is controlled by 200W-120 reducer motor and encoder, which makes the pressing depth more accurate and convenient to operate,the die-cutting part is equipped with a safety cover,the machine does not operate if the cover door is open or not tightly secured.

Oil tank,hydraulic system:The machine uses 46# anti-wear hydraulic oil, the system uses 5.6KW motor + oil pump, solenoid valve control.

assemble and unassemble the wooden knife mold by the clamping cylinder.

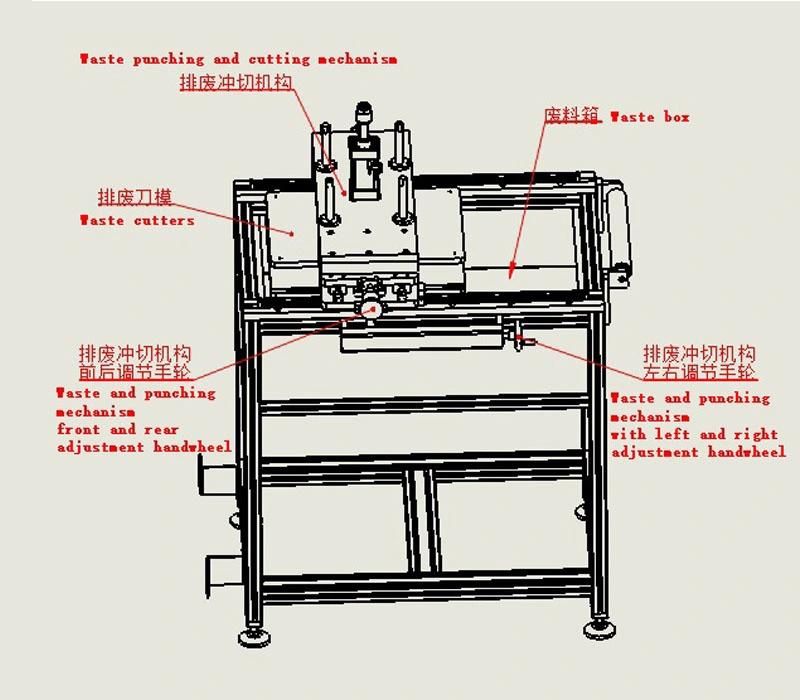

assemble and unassemble the wooden knife mold by the clamping cylinder. 2.Punching device:

2.Punching device: 3.Material storage,laminating,sheet cutting:

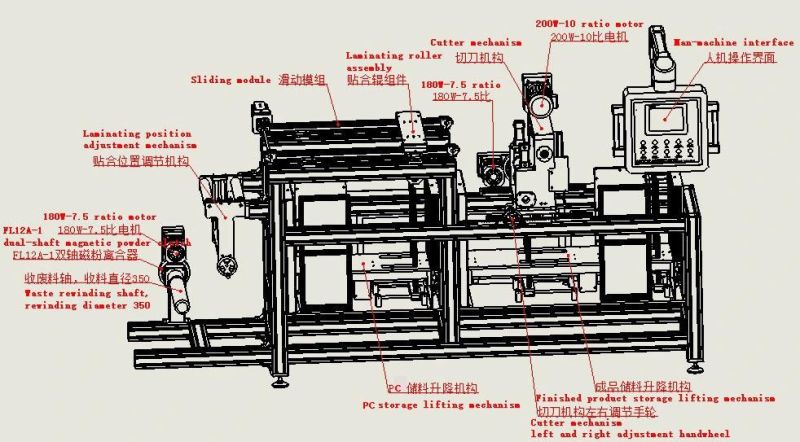

3.Material storage,laminating,sheet cutting: Waste rewind shaft:3 inch inflatable rewind shaft with rewinding diameter of 350MM,the rewinding shaft is driven by a motor and magnetic powder clutch.

Waste rewind shaft:3 inch inflatable rewind shaft with rewinding diameter of 350MM,the rewinding shaft is driven by a motor and magnetic powder clutch.

The laminating uses servo motor to drive the sliding module as the power,Move the laminating roller left and right to laminate the products,high precision.

The laminating roller is powered by a cylinder to up and down.

PC sheet storage lifting mechanism and finished product storage lifting mechanism.

The lifting uses servo motor as the power, gear, rack drive

High precision,accurate positioning,rising and falling datas can be set through the man-machine interface.

Sheet cutting:The cutter mechanism uses 200w-10 ratio motor to drive the eccentric driving wheel through the chain.

The pulling rubber roller are driven by 180w-5 ratio of motor + dual-axis clutch.The tension is adjusted by clutch and controlled by ammeter.

The cutter mechanism can be adjusted left and right by adjusting the handwheel.

SIEMENS driver,other brand is optional

CE certificate: