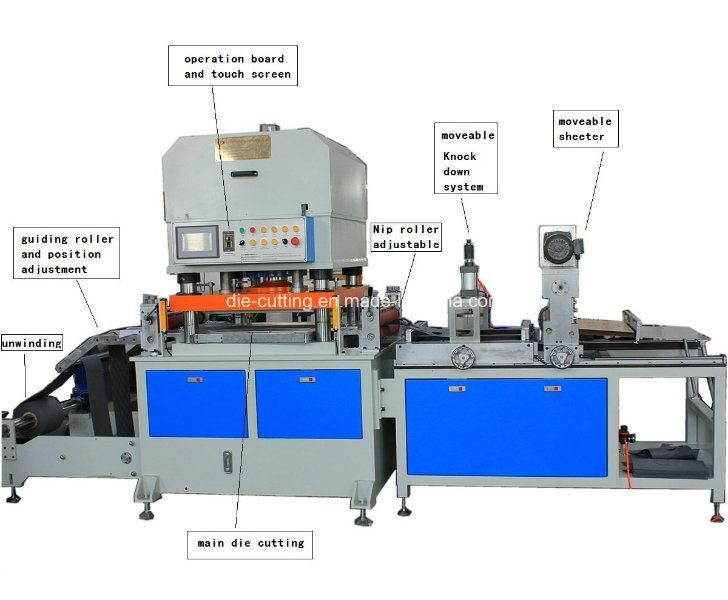

40 Ton EMI Gasket Die Cutting Machine

Kunshan Dapeng Precision Machinery Co., Ltd.- Species:Round Applanation Die Cutting Machine

- Imprinting Type:Platen

- Placing Form of Template:Horizontal

- Die Cutting Tool:Laser Die Cut Mold,Wooden Knife Mold,Steel Mold

- Computerized:Computerized

- Automatic Grade:Automatic

Base Info

- Model NO.:DP-40Tons

- Application:Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials, Earthquake Products

- Cutting Size:650X600mm,800X600mm

- Color:Can Be Choosed ( Grey,Blude , White etc)

- Cutting Pressure:40 Ton

- Feeding Width:650mm

- Driven Motor:7.5kw

- Transport Package:Wooden Case

- Specification:650X600mm 100*800mm etc

- Trademark:DAPENG

- Origin:Jiangsu Suzhou

- HS Code:844110000

- Production Capacity:30 Set Every Month

Description

Basic Info.

Model NO. DP-40Tons Application Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material, EMI Shielding Materials, Earthquake Products Cutting Size 650X600mm/800X600mm Color Can Be Choosed ( Grey/Blude / White etc) Cutting Pressure 40 Ton Feeding Width 650mm Driven Motor 7.5kw Transport Package Wooden Case Specification 650X600mm 100*800mm etc Trademark DAPENG Origin Jiangsu Suzhou HS Code 844110000 Production Capacity 30 Set Every MonthProduct Description

Best selling high efficiency hydraulic die cutting machineFeature:

1. Special body mechanism design

2. Electric control system adopts the world famous brand PLC and man-machine interface control

3. Hydraulic control system adopts quick loop

4. With the hydraulic motor drive, noise reduction, speed stability 2012 best selling high efficiency hydraulic die cutting machine for shoes

5. The machine adopts the imported sigle-chip microcomputer control of feeding. Accurate precision, simple operation; Can set the feed length and number.

6. Infrared safety electric eye system and mult-function security devices to ensure safety.

7. Adopt imported hydraulic system, low noise. And two-stage function of the presure is adjusted so that accurate and stable pressure. Automatic feeding to 3-4 times the efficiency of higher than the general press, and staff savings.

8. Use of hydrulic motors, reduce noise and rotation stability.

Application

Used for cutting pvc, fabric, cardboard, rubber, sponge, bag, non woven, and other non-metallic materials in various industries;

Extremely suitable for cutting multiple layers of material at one time;

| Model | Working Area | Max Tonnage | Max Feeding Width | Drive Motor | Weight | Outline Dimension | Position Accuracy | Power |

| DP-650 | 650mm*600mm | 40t | 650mm | 7.5HP/5.5KW | 3 Ton | 1940mm*1500mm*1790mm | ±0.01 mm | 380V 50HZ |

| DP-650 | 850mm*600mm | 40t | 850mm | 10HP/7.5KW | 3.4Ton | 2140mm*1500mm*1790mm | ±0.01 mm | 380V 50HZ |

| DP-650 | 1000mm*800mm | 80t | 1000mm | 15HP/11..2KW | 4.5Ton | 2290mm*1500mm*1790mm | ±0.01 mm | 380V 50HZ |

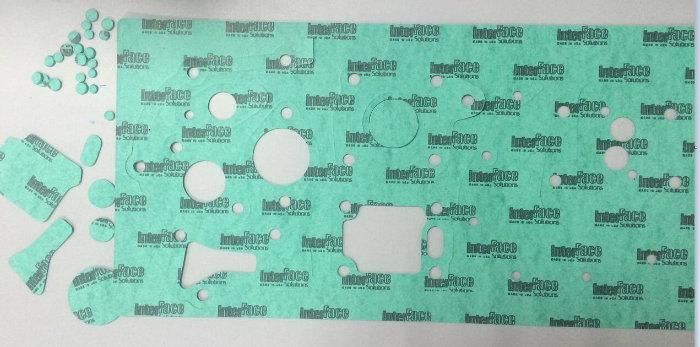

Sample :