Hot Melt Adhesive Bottom Sewing Machine

Wenzhou Qianfeng International Trade Co., Ltd.- Sewing Bag Width:800mm

- Bag Bottom Folding Width:16-25mm

- Production Speed:25-40PCS,Min

- Main Power:3kw

- Heating Power:1.5kw

- Installing Dimension:5000*1500*1300mm

Base Info

- Model NO.:QF-RRJ

- Machine Weight:1000kgs

- Conditaion:New

- Hs:8452219000

- Transport Package:as Your Reqeust

- Specification:GSG

- Trademark:Qianfeng

- Origin:Wenzhou, Zhejiang

- HS Code:8452219000

- Production Capacity:300 Set Per Month

Description

Basic Info.

Model NO. QF-RRJ Machine Weight 1000kgs Conditaion New Hs 8452219000 Transport Package as Your Reqeust Specification GSG Trademark Qianfeng Origin Wenzhou, Zhejiang HS Code 8452219000 Production Capacity 300 Set Per MonthProduct Description

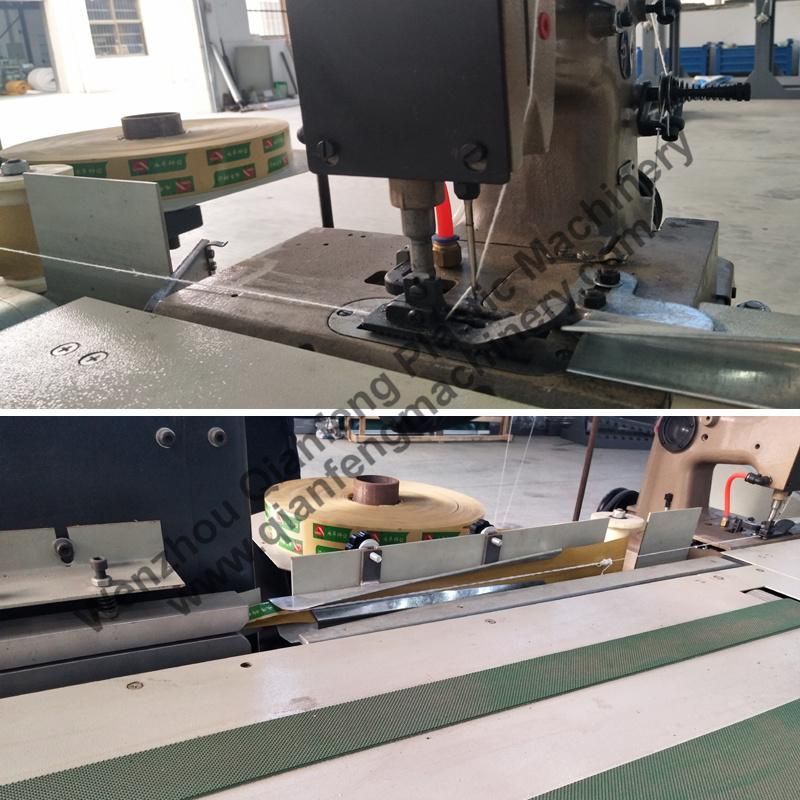

Hot Melt Adhesive Bottom Sewing Machine For Plastic and Paper Bag

Main Technical Parameters:

| Model | QF-RRJ |

| Production speed | 25-40PCS/Min |

| Heating power | 1.5kw |

| Main power | 3kw |

| Machine Weight | 1000kgs |

| Installing dimension | 5000*1500*1300mm |

Peformance And Characteristics:

This new machine is suitable for sealing the bottom of paper bag, woven bag, paper and plastic laminated bag. It is manual feeding, automatic sewing, wrap paper tape, press, cut paper, automatic stack and counting function. The sealing of bag is better after sewing, wrap paper tape and press.

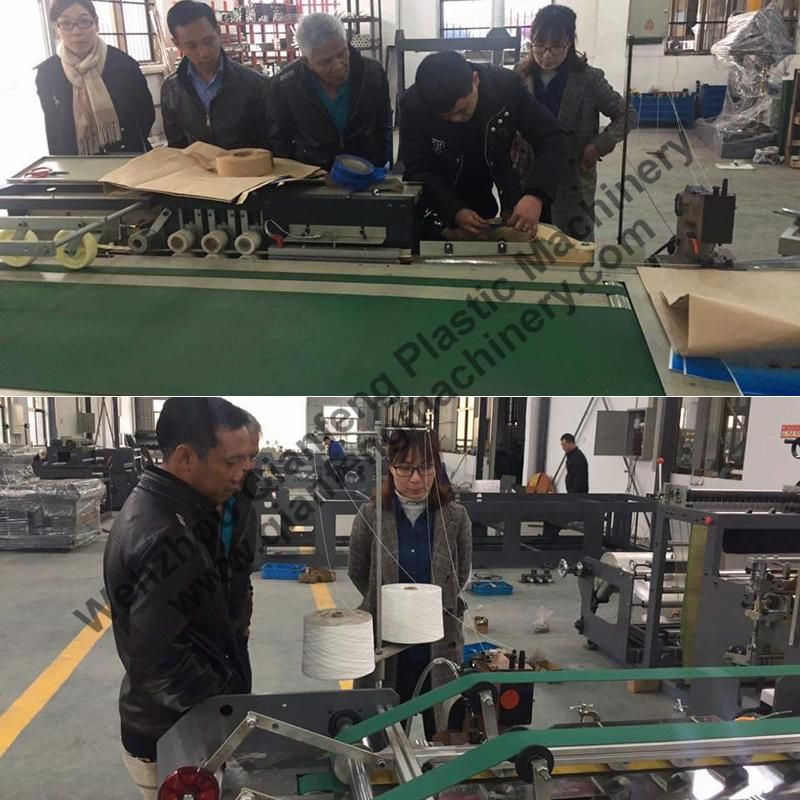

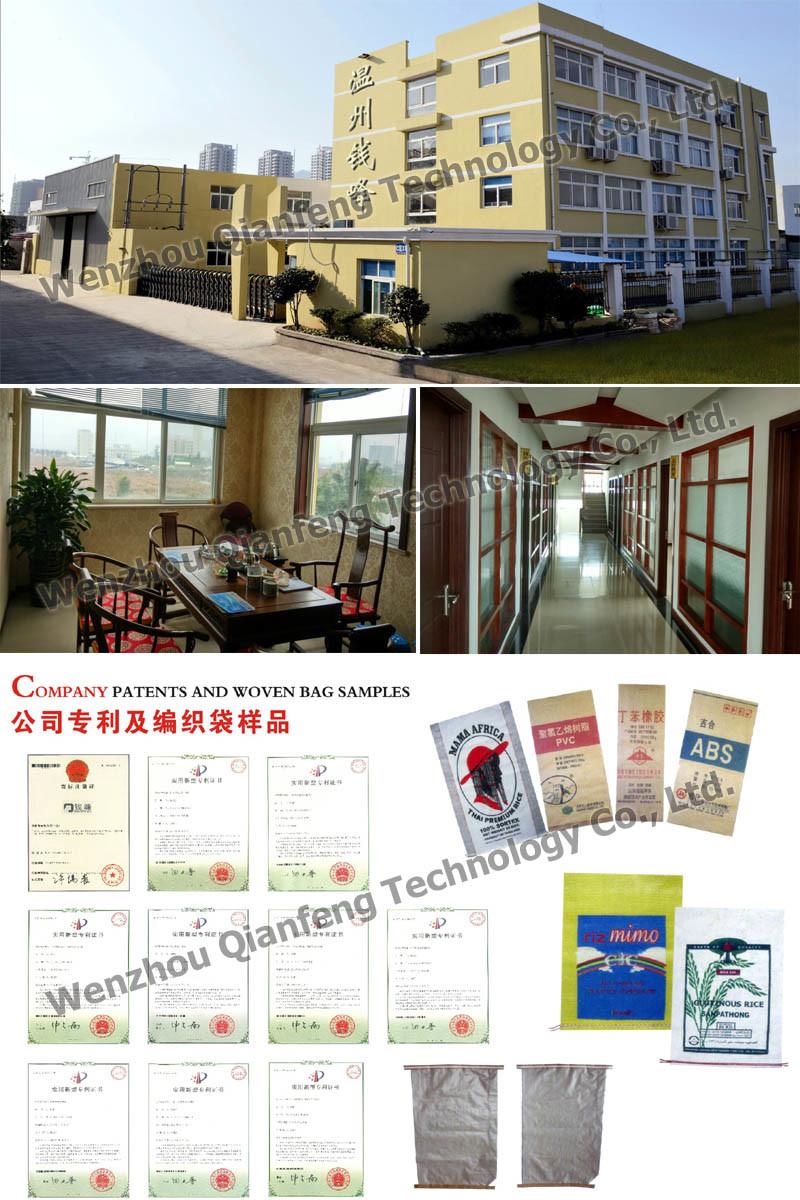

Machine photos and patents:

Old factory:

New factory:

Advantage&Service

1. several senior engineers service in our factory, all the year round, with our best after-sales.

2.Machines with quality guarantee for one year, life-long maintenance.

3.A lot of machines can be monitored via Internet, solve customer requirements immediately

4.Several senior engineers innovate and reform the technology continuous, in order to ensure the quality of mechanical stability.

5.Undertake various non-standard machinery, solve the customers' special requirements

Contact Information

Sales Manager: Rukiya Lam

Address:C37, Economic Development Zone, Aojiang, Pingyang, Wenzhou, Zhejiang, China

Website and Showroom:

wzqianfeng.en.made-in-china.com

http://wzqianfeng.en.made-in-china.com/

Contact us now, expect the cooperation with you!!!!