Roll to Roll High Precision Three Axises Automatic CCD Visual Alignment Die Cutting Machine for Circuits

Shenzhen Vility Automatic Machinery Co., Ltd.- After-sales Service:Video Support or Go Overseas

- Warranty:1 Year

- Species:Die Cutting and Creasing Machine

- Imprinting Type:Platen

- Placing Form of Template:Vertical

- Die Cutting Tool:Steel Blade

Base Info

- Model NO.:VT450CR

- Computerized:Computerized

- Automatic Grade:Automatic

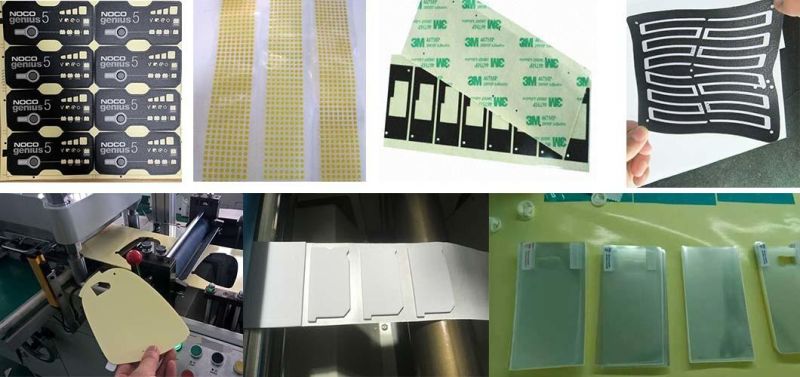

- Application:Paper Packaging Materials, Stickers Products, Heat Insulation Material, Insulating Materials, Dust-proof Material

- Control System:PLC

- Motor:Servo Motor

- Degree of Automation:Fully Automatic

- Feature:High Precision

- MOQ:1 Set

- Shipment Term:Fob Shenzhen

- Axis Number:3

- Weight:2000kg

- Power:1.5kw

- CCD Positioning Accuracy:0.02mm

- Punching Accuracy:0.04mm

- Air Consumption:2.6L , Cycle

- Punching Speed:5000 P , H

- Voltage:380V

- Material:Label, Stickers, Panels, Film

- Transport Package:Polywood

- Specification:L1500 * W900 * H1750mm

- Trademark:Vility

- Origin:China

- HS Code:8441100000

- Production Capacity:30,Month

Description

Membrane switch, conductive film, Mobile phone panel, PVC, FPC, PET film, foil and other roll maerial and so on.

1. The XYθ alignment platform and CCD are fixed on the die-cutting machine, so that the alignment is stable and the jitter is small.

2. The material is fixed on the loading suction platform, easy to operate.

3. The punching precision is completely controlled by CCD and the positioning is accurate.

4. Man-machine interface control + button switch, can set a variety of functions and parameters, easy to operate.

5. Safety pressure plate, photoelectric switch, emergency stop button, comprehensive safety protection.

6. CCD automatic positioning punching, can automatically adjust the CCD field of view according to the size of the material.

7. The CCD automatically calculates the spatial position of the material and the mold according to the Mark point on the material, and instructs the motor to control the adjustment platform X, Y, θ, and automatic punching.

8. After the equipment is adjusted, the punching will be completed automatically, the number of punching can be automatically set, and an alarm device is installed to facilitate management.

9. Can be customized according to customer requirements to meet different requirements.

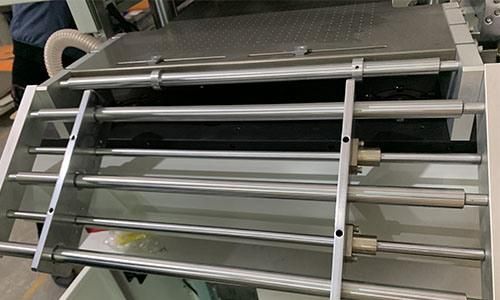

Feeding Frame:

It adopts high quality 304 stainlesss steel, its surface smooth, protect material from scratching.

The entire feed frame is moval according to customer material.

The material is fixed on the loading suction platform, easy to operate.

Alignment XYθ platform

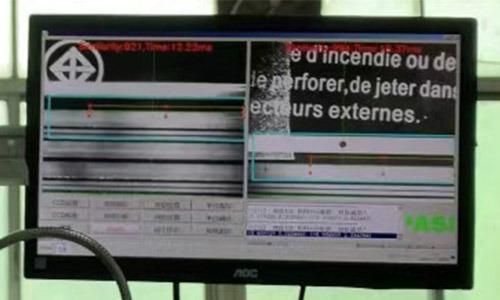

CCD Vision Alignment:

CCD automatic positioning punching, can automatically adjust the CCD field of view according to the size of the material.

The CCD automatically calculates the spatial position of the material and the mold according to the MARK point on the material, and instructs the motor to control the movement of the adjustment platform XYθ to automatically punch.

Cutting method: knife/steel mold.

The quaternion CCD vision flat knife die-cutting machine system is developed for high-precision die-cutting products with complex processes.

According to the size of the target and the accuracy requirements for die-cutting quality, the number of cameras in the vision system is determined. Use multiple cameras to locate the target feature (MARK point, edge, corner information, etc.), and use visual guidance technology to determine the relative position of the die and the material to be cut, and adjust the product so that it is flush with the die, then process die cutting.

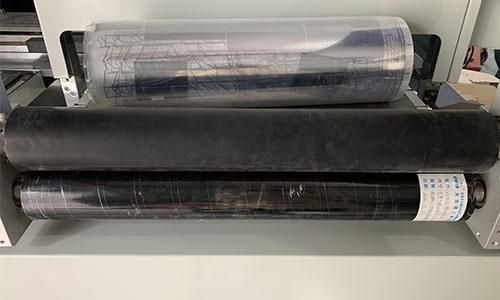

Pulling Roller:

Silicone roller has good wear resistance, not easy to age, anti-static, moisture-proof and self-adhesive dust removal.

It also has high resilience, high temperature resistance, and wear resistance characteristics.

Each time the die-cutting machine punches, the pulling roller will pull a jump distance of the product, and the unwinding machine then unwinds. Ensure the working efficiency of punching.

PLC + Touch Screen Control Panel:

All of machines were packed by wooden, it protect the machines from hitting. We've exported machines to Europe, Southeast Asia, Southeast etc. Representitive companies have CCL, SJS, Excel, Cymmetrik, Saule S.A, ect.

1.10 years professional production experience in printing punching machinery industry.

2.5000 m^2 production workshop, strong production capacity.

3.Professional senior engineer develop the best solution.

4.Strict quality control system, CE certificate available.

5.Main components adopt imported international famous brand.

6.Timely delivery, half of an hour to shenzhen port.

7.Professional after-sale service, Email will be reply in 24 hours.

8.Site installation or video support and commissioning in your factory

9.We got many machine development patents, software system can be upgrated by free in lifelong.

10.All of our machines can have one year guarantee and lifelong maintenance.

11.Giving a free technical training for your employees.

* Lifelong maintenance

* Spare parts

* Video technical and online support

* Field maintenance and repair service

* Engineers available to service machinery overseas.

Shenzhen Vility Automation Machinery Co., Ltd,established in 2010, is located in Baoan District, Shenzhen, where high-tech industries are concentrated in R & D and production, Covers an area of 5000 square meters and has around over 10 years history and experience of making machinery. People-oriented, technological progress and service-oriented are the company's development guidelines. VILITY is composed of two groups of words, Victory & Ability, Victory & Quality, and contains our corporate spirit to win with strength and win with quality.

Vility has total 3 workshops so far, about 60 workers, established sales department, purchasing department, R&D department, production department and after-sales department. Our production capacity is about 30 sets per month.

Q1: Are you manufacturer or trade company?

A1: We're manufacturer in shenzhen China, who have factory with about 5000m2 square area, warmly welcome to visit our factory at any time!

Q2: What's the leadtime?

A2: Usually production leadtime is 30-45 days after everything confirmed and getting payment. For standard size machine, leadtime 30 days is enough.

Q3: How do you give us training?

A3: We will provide video training and operation manuals, if it is necessary, our engineer will go to overseas for service.

Q4: How about the machine installation?

A4: Basically, when customer received machines, just need to connect them together, connect power and air, but we still provide video guidance and installation manual, or video on-site support.

Q5: Do you supply spare parts?

A5: Yes, we also can supply spare parts with machine.

Q6: What is the payment term and shipping term?

A6: Our payment term is 100% TT, 50% deposit, balance 50% need to be paid off before shipping. Shipping term is FOB shenzhen.

Q7: What is the speed of service in case of machine will not work?

A7: If customer have any problem, you could call us or leave message to us, we will response at first time(7*24 hours).