Die-Cutting Machine Flat Knife Die Cutting Machine One Line CNC Can Laminate

JiangSu Weixiangrui Intelligent Equipment Technology Co., Ltd.- After-sales Service:Over Sea After Sale Service

- Warranty:1 Year

- Species:Die Cutting and Creasing Machine

- Imprinting Type:Platen

- Placing Form of Template:Horizontal

- Die Cutting Tool:Metal Mold

Base Info

- Model NO.:WXR-300,350

- Computerized:Computerized

- Automatic Grade:Automatic

- Application:Stickers Products, Heat Insulation Material, Insulating Materials

- Transport Package:Wooden Case

- Origin:China

Description

Feature

1. PLC program control, touch screen operation, the fastest speed can reach 18,000 times/hour.

2. Machine design: feeding frame adopts fine-tuning arc design, the use of adjustment is more convenient and fast, die-cutting position adopts hole positioning lock, will not cause die-cutting products shift, die-cutting more precise, the discharging part adopts small hole set, the machine has the advantages of high precision, pressure stability, low noise, fast speed and so on.

3. Die cutting part: can install engraving die, wood die, plastic plate die, etching die, QDC die, can easily achieve two sets of punching, die cutting part is equipped with safety light curtain protection device, to ensure the safety of operators.

4. Automatic oil supply system, ensure the durability of the machine easy to wear parts.

5. Can be operated before and after online, die cutting punching complex products.

Applicable Material

Electrical special rubber pad, silica gel pad, Velcro, conductive adhesive, strong double-sided adhesive, 3M, SONY special adhesive, adhesive products, light source, air filter, protective film, optical film, black and white glue, Myla, easy pull glue, foam glue, IT industry film switch, automotive manufacturing industry used in the adhesive products die-cutting punching type.

Optional Configurations

1. Hot stamping

2. Punching

3. Laminating

4. Adding conveyor belt

5. Full-cut for die cutting

After-service

1. Warranty for machine: 12months.

2. After-service: A reply within 24 hours.

3. A free training in our factory available before delivering machines.

Packaging and shipping

Fix machine on the pallet by screws,make sure safety during transportation.

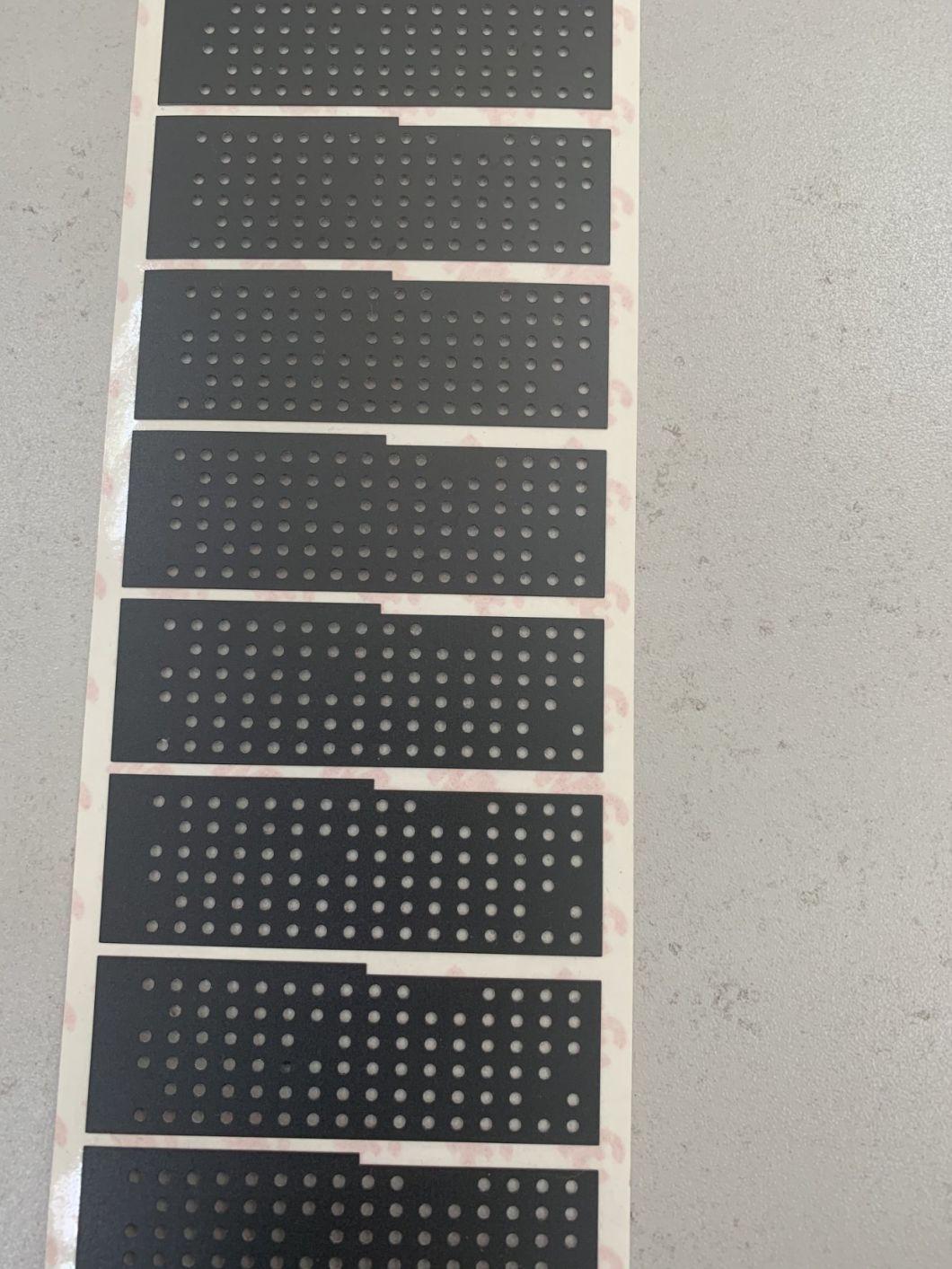

Die cut samples

Related products

Why us

Jiangsu WeiXiangRui Intelligent Equipment Technology Co.,Ltd, integrate produce, sales,R&D as one automatic Industry enterprise. our company have enagged in die cut area over 10 years. Mainly products include: slitting machine, full Automatic Cutting machine,laminating machine,..also customize personal customize service. Our products combined with Germany,Finland, Hungary etc country's high procession technology and quality ,more prizes from our clients our products widely use in electronic . IT, packaging .medicine ,car industry,printing etc industries. Our products have advantages below

A:strong expansibility.upgrade system or customize machine according to customers' requirements.

B:Modular design: more convenience and powerful.

C:machine parts characters :use the high quality raw material, worldwide famous brand,Long using lifetime and high stability.

D:machine process :according international standard process.Quenching tempering internal /external procession grinding.

CNC ,wine cutting ,milling ,drilling ,ensured each part procession And durable.