Silicon Rubber Conductive Fabric Diffuser Sheeting Machine

Kunshan Hexin Precise Machinery Co., Ltd.- Warranty:1year

- Classification:Double-blade Cutter

Base Info

- Model NO.:HX-360Y

- Driven Type:Electric

- Type:Industrial Cutter

- Blade Material:Stainless Steel

- Computerized:Computerized

- Model:Hx-360d

- Voltage:220V,380V

- Power:1HP

- N.W.:260kg

- Gw.:280kg

- Cutting Length:0.1-9999.9mm

- Cutting Width:1-360mm

- Measurement:780*920*1070mm

- Transport Package:Plywood Case

- Specification:CE ISO

- Trademark:HEXIN

- Origin:China Jiangsu

- Production Capacity:200 Sets, Month

- Package size per unit product:150.00cm * 100.00cm * 150.00cm

- Gross weight per unit product:230.000kg

Description

Basic Info.

Model NO. HX-360Y Driven Type Electric Type Industrial Cutter Blade Material Stainless Steel Computerized Computerized Model Hx-360d Voltage 220V/380V Power 1HP N.W. 260kg Gw. 280kg Cutting Length 0.1-9999.9mm Cutting Width 1-360mm Measurement 780*920*1070mm Transport Package Plywood Case Specification CE ISO Trademark HEXIN Origin China Jiangsu Production Capacity 200 Sets/ MonthPackaging & Delivery

Package size per unit product 150.00cm * 100.00cm * 150.00cm Gross weight per unit product 230.000kgProduct Description

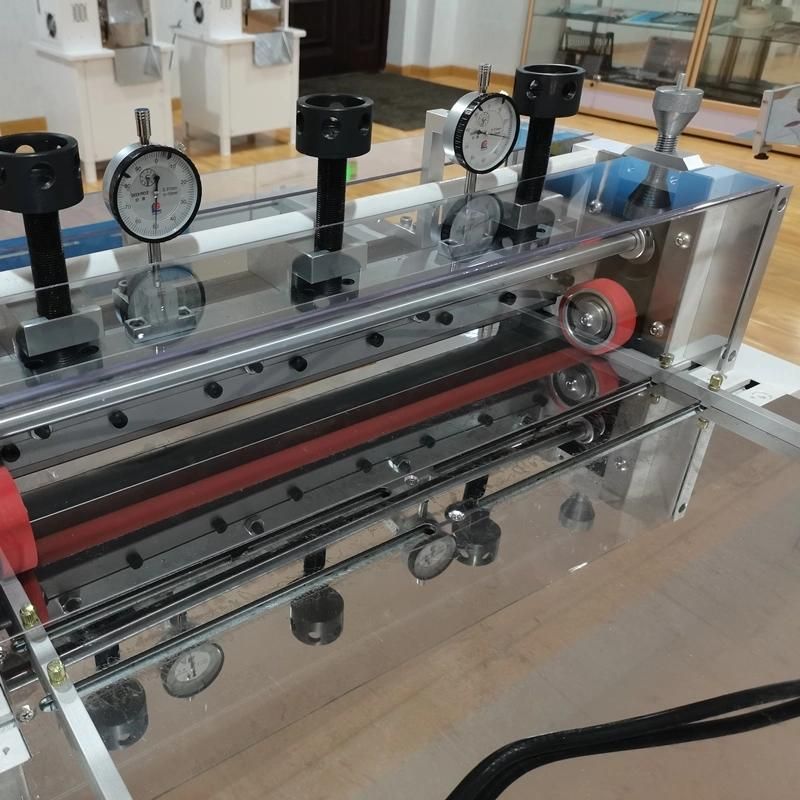

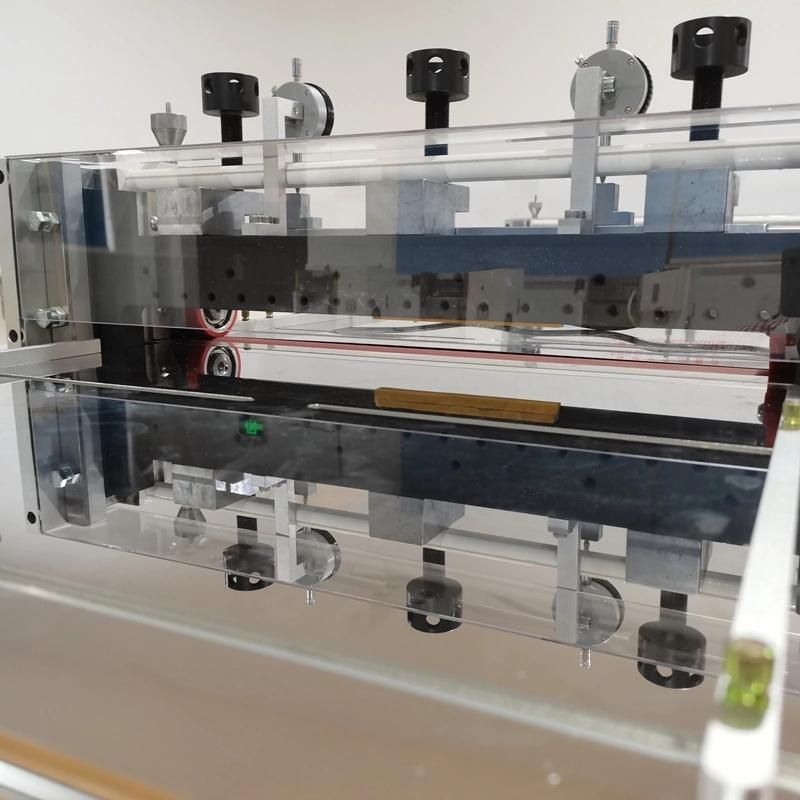

Silicon Rubber Conductive Fabric Diffuser Sheeting Machine

Brief introduction

This machine is designed for pre-printed material, like label, sticker, reflective strap, paper, PET, PC, etc. It adopts an imported photoelectric sensor to achieve precise cutting.

Samples Show

This cutting machine can cut more than following material:

SpecificationParameters:

Model | HX-360y |

Voltage | 220/380V |

Power | 750W |

N.W. | 260kg |

GW. | 280kg |

Cutting Length | 0.1~9999.9mm |

Cutting Width | 1~360mm |

Measurement | 780x920x1070mm |

Machine Features:

1. Max material width: 360mm;

2. Tolerance: 0.05mm, Precision: 0.1mm;

3. Material thickness range: 0.5mm-15mm;

4. Both kiss cut and full cut are available, full cut is for standard machine, and kiss cut is an option;

5. This printed paper roll to sheet cutting machine employs a man-machine interface and PLC system to control;

6. This printed paper roll to sheet cutting machine adopts an imported photoelectric sensor and suction device to achieve precise cutting;

7. This printed paper roll to sheet cutting machine can preset cutting length, speed, and quantity, and it will memorize them when it runs next time;

8. This printed paper roll to sheet cutting machine adopts a servo motor to make sure accuracy;

9. Operation is easy with a touch screen.

Configuration sheet:

Touch Screen | WEINVIEW | Made in Taiwan |

Programmable Controller | MITSUBISHI | Made in Japan |

Servo Driver | DELTA | Made in Taiwan |

Servo Motor | DELTA | Made in Taiwan |

Motor of cutting knife | SL | Made in Taiwan |

AC Contactor | SNAIDER | Made in China |

Solid State Relay 20A | OMRON | Made in Japan |

Photoelectric sensor | PANASONNIC SUNX | Made in Japan |

Options:

1.Kiss cut knife

2. Hot cutting knife

3. Conveyor belt

4. Unwinding machine

5. Fixture

1. We are a factory, and the price is favorable.

2. We have strict QC system.

3. We offer a free after-sales service for one year.

4. Our engineers are available to service machinery overseas.

5. Our machines have been sold to over 40 countries.

Machine show

1. Q: Are you a factory or trading company?

A: We are a factory and manufacturer

2. Q: Where is your factory located in ? How can I visit there?

A: Our factory is located in Kunshan which is very near from Shanghai, and our detailed address is: Factory 9, No. 157, Wulian Road, Yushan Town,

Kunshan, Suzhou, Jiangsu, China. If you fly to Shanghai hongqiao airport or Pudong airport, we can pick you up by car from there. We welcome all our clients, home and abroad, to visit us.

3. Q: what are your main products?

A: Our main products are belt cutting machines, slitting machines, sheeting machines, laminating machines and die cutting machines.

4.Q: Which industries can use your machines ?

A: All industries need to cut (include full cutting and kiss-cutting), slit, laminate, die cut raw materials can use our machines.

5.Q: How to control the quality in your factory ?

A: Quality is priority. We control the quality of our products strictly, from the incoming materials to the finished products. Our factory has obtained CE & ISO Certification

6. Q:If there are no machines available from your list, could we customize non-standard machines from you ?

A: Yes, we have our own professional design engineers, and can customize products according to your requirements.